It is best to start the setup of the pelletizing line with the pellet mill itself. It usually draws the most attention from clients, and gap adjustments are easier in silence before starting up the dryer and hammer mills. A common issue occurs when setup and startup begin at the start of the line, and there's a rush to adjust the pellet mill when dried material is already entering the conditioning bin. The noise can make communication difficult.

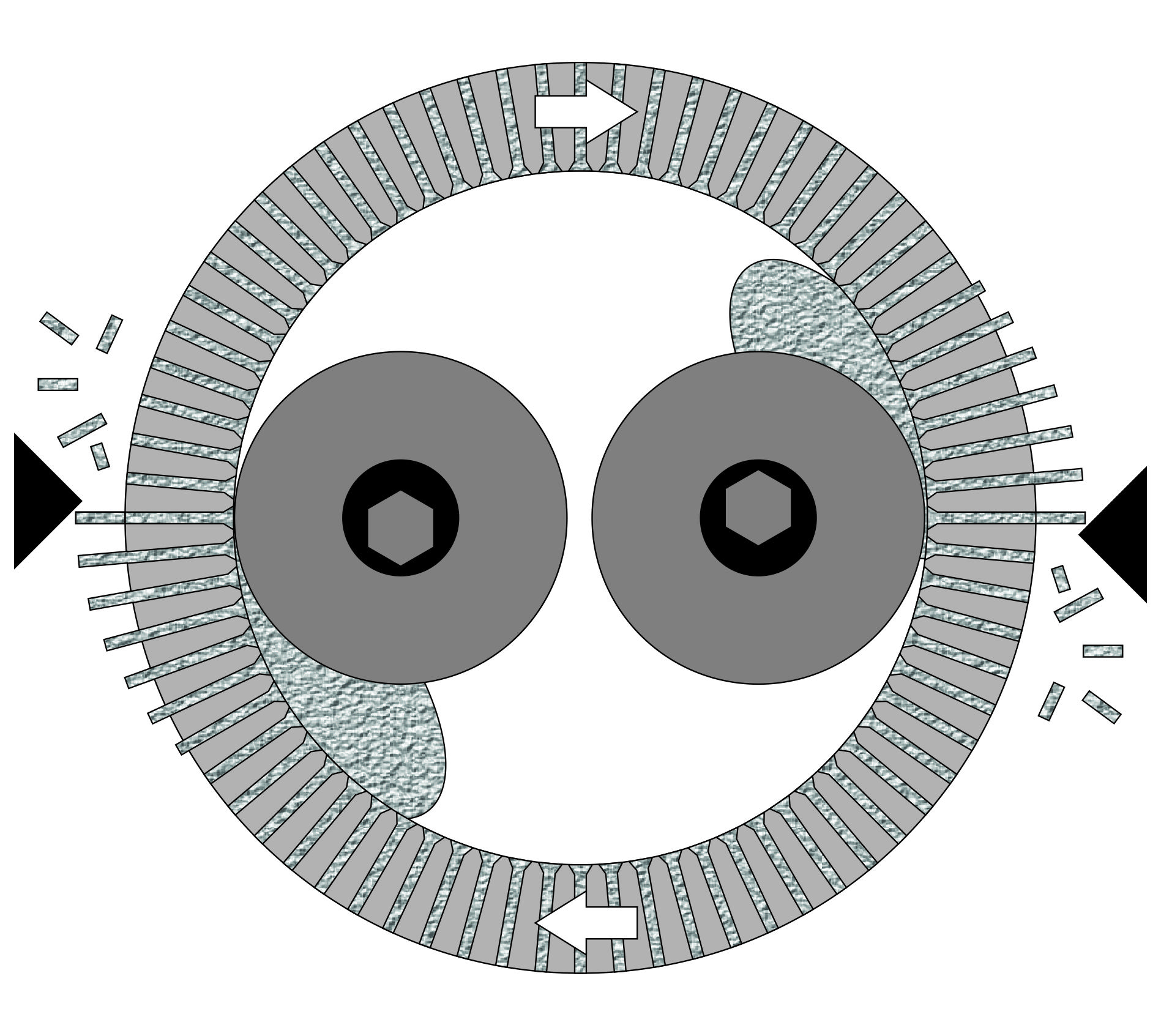

Contact between rollers and the die is a highly negative phenomenon, leading to rapid wear of both surfaces, and in extreme cases, even to galling and damage to the expensive die. With too large a gap, material under pressure flies out from under the ring like mud from a tire, stopping the pressing process. So, where is the sweet spot where you achieve maximum productivity with minimal costs?

Contact between rollers and the die is a highly negative phenomenon, leading to rapid wear of both surfaces, and in extreme cases, even to galling and damage to the expensive die. With too large a gap, material under pressure flies out from under the ring like mud from a tire, stopping the pressing process. So, where is the sweet spot where you achieve maximum productivity with minimal costs?

It all depends on the type of material, its particle size, and flowability. The easier the material is to pelletize, the larger the gap can be left. For compound feed and MDF dust, the gap is set around 0.6-0.8mm (0.024-0.031 inches), for wood and other biofuels 0.2-0.4mm (0.008-0.016 inches). These are typical cases on properly functioning equipment. Often, realities involve non-ideal geometry of the die, rings, and runouts on the pellet mill shafts. If the die track has a runout of up to 0.3mm (0.012 inches), then the rollers are brought to light contact. Proper adjustment is determined by the sound of tracks lightly rubbing without rollers rotation when the pellet mill is on without feeding material. After 5-10 hours of operation, the die track levels out, allowing a gap to be set to reduce wear rates.

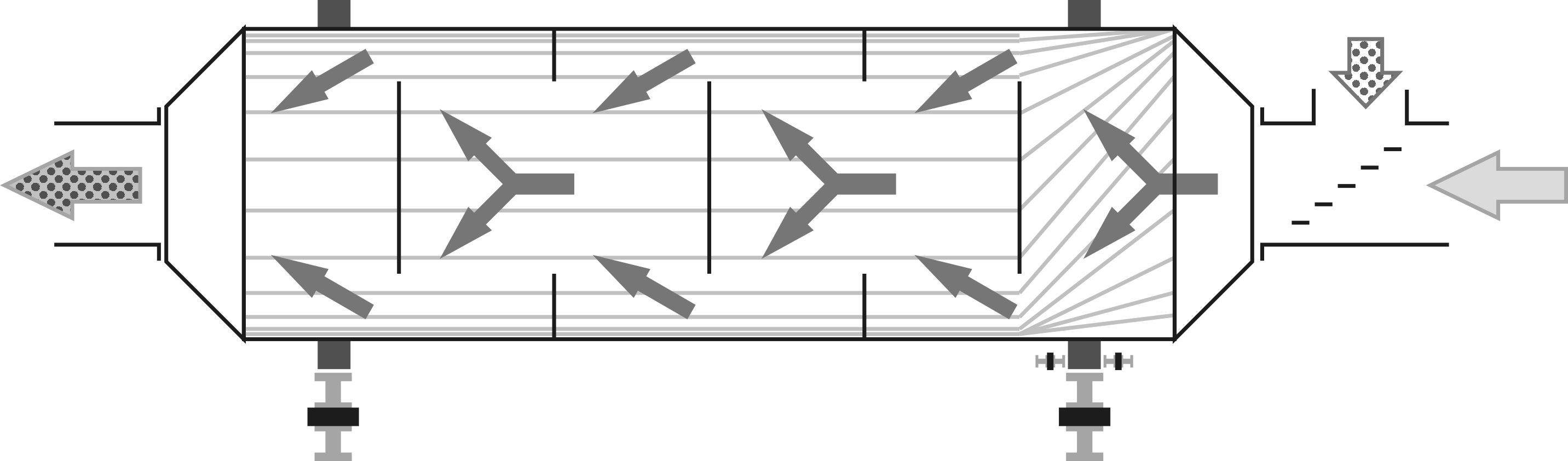

Inspection and preparation of the pellet mill are usually detailed in the operating manual. The preparation order typically includes checking the correct connection of cables, presence of lubricant in the main and auxiliary drive gearboxes, checking the grease supply to rollers and the central bearing, adjustment of sealing between the door and die diffuser, test run for 5-10 minutes with the rollers retracted from the die and checking bearing temperatures, and adjusting gaps between die tracks and rings.

After standard checks, a no-load run should be done to test the safety systems. It is advisable to simulate opening the pellet mill door and triggering the safety systems by unscrewing the proximity sensors. Overheating or overcurrent protection can be simulated by lowering the settings. At this time, check how the control system manages related equipment. For example, in an emergency stop of the main drive, the drives for the mixer and feeder should also be cut off to prevent material from overwhelming the static die. The feeder should stop if the mixer is halted to prevent a clog between them. Similar checks should be conducted on all equipment with multiple technologically interconnected drives.