Drying material that is suspended in an airstream is as old as the world itself. The most basic way to dry wood chips from 14-18% to 10% moisture is to direct a heat gun at the inlet of a standard hammer mill with pneumatic transport. A few turns in the stream with the hammers, 3-5 seconds of flying through the pipes, and in the cyclone, excess moisture is removed, producing high quality pellets. The high velocity of the drying agent flow over the particles significantly reduces the necessary drying time.

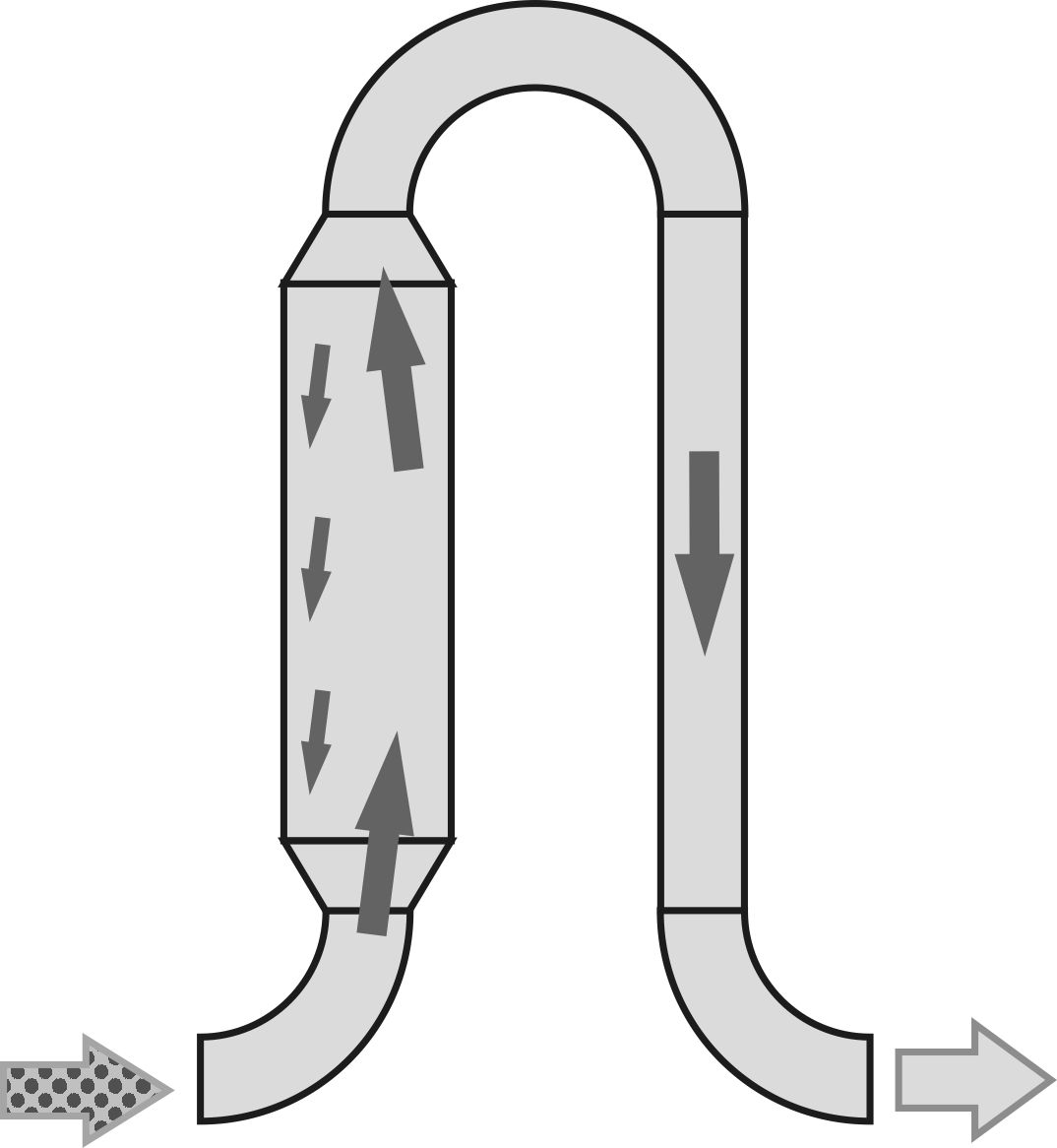

To extend the time particles spend in the hot environment, pipes with varying cross-sections are used. The diameter of the upward flow pipe is roughly twice that of the downward flow pipe. As the flow transitions to a larger diameter, the average speed drops by four times, and the material is shot into a cavity where it slows down due to hot air and creates turbulence. At optimal speeds of the circulating thermal agent, the material can even temporarily settle in the expanding sections only to be picked up again by the incoming stream. This creates a fountain effect with the sawdust, where drier and lighter particles are more likely to exit, while larger and heavier ones continue circulating until they dry and undergo partial fragmentation. Hence, these dryers are also known as aero-fountain dryers. A diameter change in the pipe reduces flow speed by a factor of four, typically from 30 m/s (98 ft/s) to 7 m/s (23 ft/s), and these are averaged values for particle mass. In reality, over half the height of the wide section stream carries at noticeably higher speeds, pushing part of the air in the opposite direction.

To extend the time particles spend in the hot environment, pipes with varying cross-sections are used. The diameter of the upward flow pipe is roughly twice that of the downward flow pipe. As the flow transitions to a larger diameter, the average speed drops by four times, and the material is shot into a cavity where it slows down due to hot air and creates turbulence. At optimal speeds of the circulating thermal agent, the material can even temporarily settle in the expanding sections only to be picked up again by the incoming stream. This creates a fountain effect with the sawdust, where drier and lighter particles are more likely to exit, while larger and heavier ones continue circulating until they dry and undergo partial fragmentation. Hence, these dryers are also known as aero-fountain dryers. A diameter change in the pipe reduces flow speed by a factor of four, typically from 30 m/s (98 ft/s) to 7 m/s (23 ft/s), and these are averaged values for particle mass. In reality, over half the height of the wide section stream carries at noticeably higher speeds, pushing part of the air in the opposite direction.

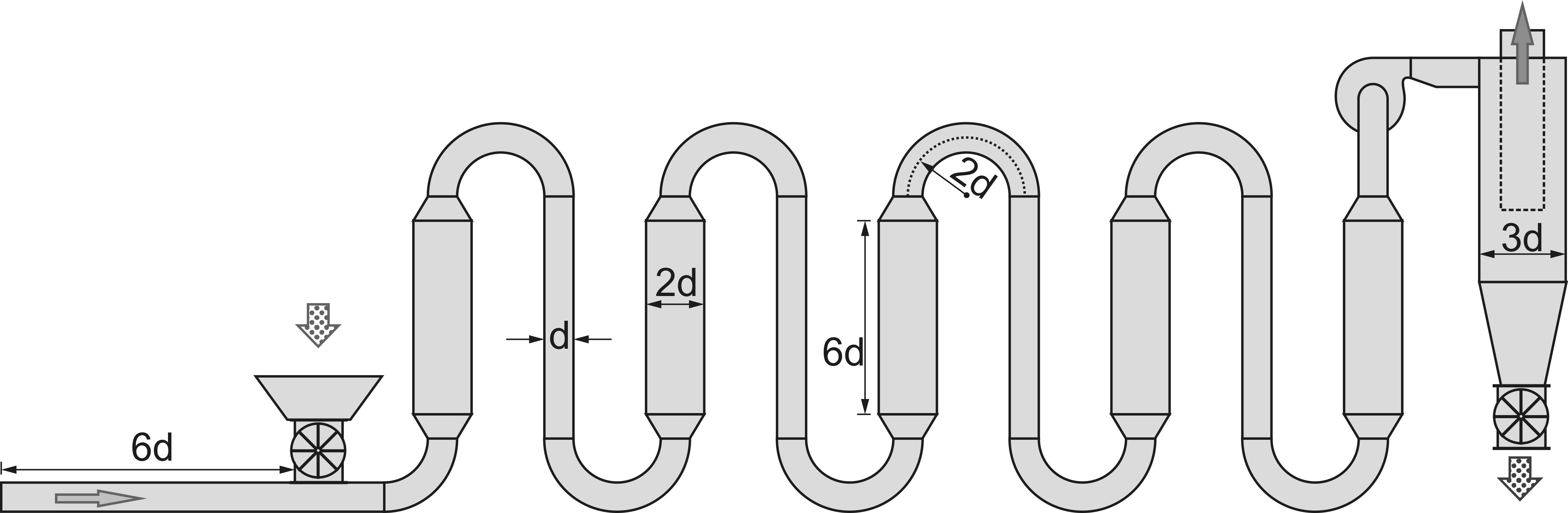

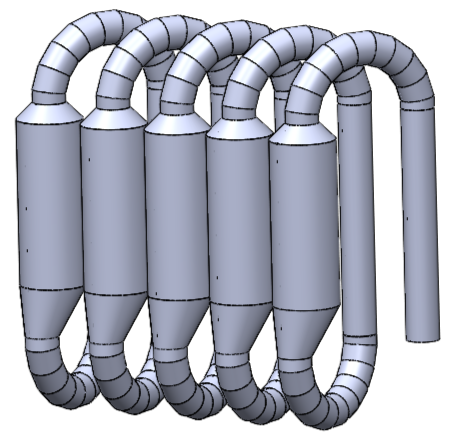

In a few seconds, the thermal agent transfers only a small fraction of its heat. To increase the efficiency of the dryer, depending on the initial moisture content of the material, between three and five "sections" are installed areas with expansions. The floating material in the flow, friction at the bends, and chaotic turbulence not only contribute to increased resistance in the flow but also require two to four times more vacuum on the fan compared to regular airflow with clean air. If the chips float easily and only increase the air mass density and its effective viscosity, gaining fluidity in the flow, then large, wet sawdust tends to clump, stick, and even block the bends. Such a setup is not suitable for drying chips, as the significant differences in aerodynamic properties of the individual wood pieces result in a prolonged delay in the first section, leading to overheating and ignition. To prevent fire, sawdust should be screened to remove chips and bark, which also tends to carry large stones.

The optimal proportions of different parts in the dryer are shown in the figure and are related to the main diameter of the pneumatic transport, where the flow speed is from 15-20 m/s (49-66 ft/s) for chips to 30 m/s (98 ft/s) for wet sawdust. The acceleration section is also necessary here, just like in a regular pneumatic transport system.

The optimal proportions of different parts in the dryer are shown in the figure and are related to the main diameter of the pneumatic transport, where the flow speed is from 15-20 m/s (49-66 ft/s) for chips to 30 m/s (98 ft/s) for wet sawdust. The acceleration section is also necessary here, just like in a regular pneumatic transport system.

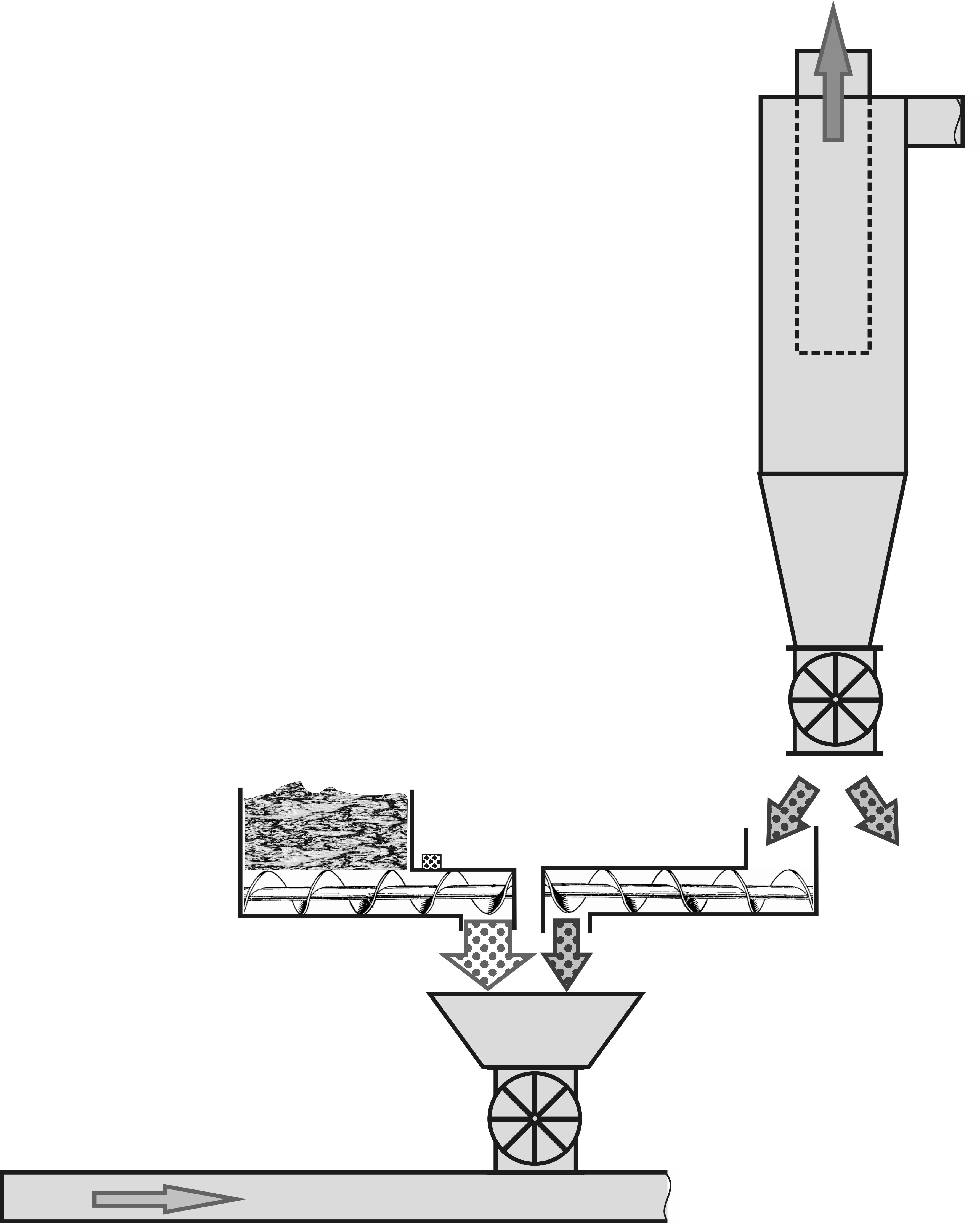

The production rate for the dry product is approximately 1 ton per hour for a "basic" diameter of d=300 mm (12 inches). The allowable moisture content for sawdust in 5 sections is 35-40%. Further extensive increase of the dryer requires thickening the walls of the air ducts and using bands to prevent collapse of wide sections. This leads to a pulsating movement of material. Uneven section loading progresses and can cause complete clumping on the lower conical surfaces, leading to overheating and ignition. Therefore, in cases where moisture content episodically exceeds 35%, it is much safer and simpler to use sawdust recirculation by sending some of the material through another loop. Yes, this will result in particles with varying moisture levels and may reduce pellet quality, though negative effects can be resolved by "curing" the material before pelleting to redistribute moisture, as well as by finer grinding or increasing the working length of the channel in the die of the pellet mill.

The production rate for the dry product is approximately 1 ton per hour for a "basic" diameter of d=300 mm (12 inches). The allowable moisture content for sawdust in 5 sections is 35-40%. Further extensive increase of the dryer requires thickening the walls of the air ducts and using bands to prevent collapse of wide sections. This leads to a pulsating movement of material. Uneven section loading progresses and can cause complete clumping on the lower conical surfaces, leading to overheating and ignition. Therefore, in cases where moisture content episodically exceeds 35%, it is much safer and simpler to use sawdust recirculation by sending some of the material through another loop. Yes, this will result in particles with varying moisture levels and may reduce pellet quality, though negative effects can be resolved by "curing" the material before pelleting to redistribute moisture, as well as by finer grinding or increasing the working length of the channel in the die of the pellet mill.

The portion of material going for redrying is regulated by the speed of the discharge screw, which must always be lower than the speed of the main screw for material dosing. The chart provides an estimation of how much material will go for additional drying rounds at each extraction percentage.

| Circle Number | Percentage of Material for Redrying | ||

|---|---|---|---|

| 33% | 50% | 67% | |

| 1 | 100 | 100 | 100 |

| 2 | 33.0 | 50.0 | 67.0 |

| 3 | 10.9 | 25.0 | 44.9 |

| 4 | 3.6 | 12.5 | 30.1 |

| 5 | 1.2 | 6.3 | 20.2 |

| 6 | 0.4 | 3.1 | 13.5 |

| 7 | 0.1 | 1.6 | 9.0 |

| 8 | 0.0 | 0.8 | 6.1 |

| Material Flow in Drying Relative to Input | 149.2% | 199.2% | 290.7% |

When collecting only a third of the material for another loop, the amount of sawdust in the flow increases by 1.5 times. Collecting half doubles it, while two-thirds triples it. This must be considered during setup, as the amount of mass in the air proportionally increases the load on the fan. At some point, the total resistance of the dryer could exceed the maximum possible suction of the fan, and section blockage with complete flow obstruction may occur.

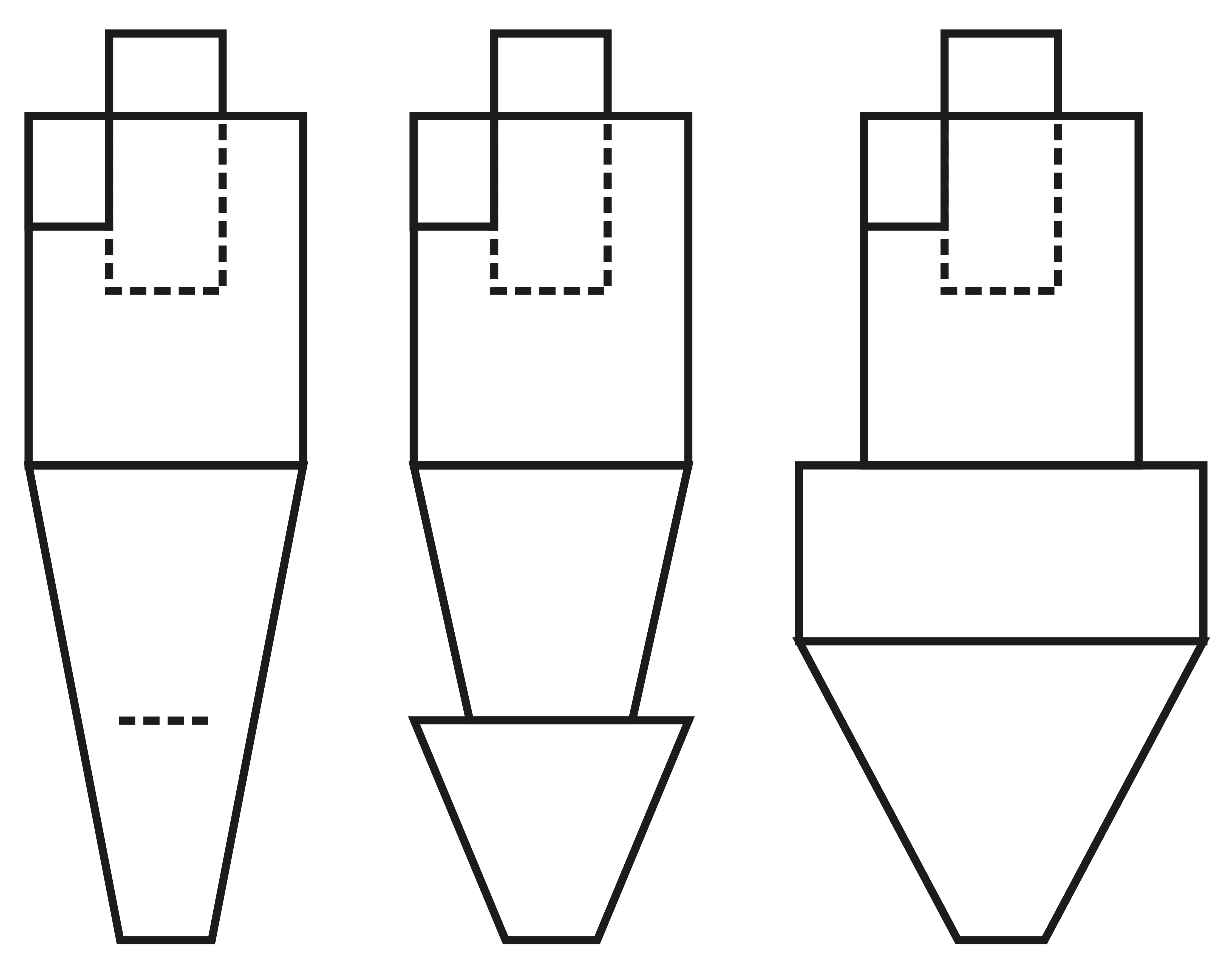

To organize material movement within the section, the lower cones are designed to be inclined. This aids in the maximum separation of wet particles from dry ones by their ability to slide on metal. The absence of a step on the side pressed by centrifugal force as the material exits the flow turn eliminates "dead zones" of clumping. On the opposite side, the broad sloped half of the cone gathers settling, slightly warmed, and dry particles for reintroduction into the flow. The illustration shows an example of compact section arrangement with inclined cones at the bottom.

To organize material movement within the section, the lower cones are designed to be inclined. This aids in the maximum separation of wet particles from dry ones by their ability to slide on metal. The absence of a step on the side pressed by centrifugal force as the material exits the flow turn eliminates "dead zones" of clumping. On the opposite side, the broad sloped half of the cone gathers settling, slightly warmed, and dry particles for reintroduction into the flow. The illustration shows an example of compact section arrangement with inclined cones at the bottom.

The optimal fan power for an installation with a capacity of 1 ton per hour is approximately 22-30 kW (30-40 hp). When processing wood shavings, it will consume about 10-15 kW (13-20 hp), and efficiency losses are minimal. However, for large raw sawdust, almost the entire nominal power may be required. The most cost-effective and relatively reliable option is a product fan running at 2900 rpm with a working wheel diameter of 600 mm (24 inches) and a width of 120 mm (5 inches). To minimize costs, the fan is placed after the dryer, before the cyclone. This allows the cyclone to be utilized with air pressure and a minimal wall thickness. Sometimes, it is possible to modify a grain hammer mill to fit the required airflow, reducing the number of units, and delivering not only dry but also crushed material ready for pelleting. An additional advantage of crushing in a hot airflow is the preservation of high raw material temperatures, which significantly reduces the load on the pellet mill. The most suitable hammer mill for these purposes resembles a product fan, with a sieve mounted around the wheel. The ends of the blades have wear-resistant paddles that act as hammers. Such hammer mills are easily scalable and can be adjusted for different air throughput and pressure based on motor speed, wheel diameter, and width.

The optimal fan power for an installation with a capacity of 1 ton per hour is approximately 22-30 kW (30-40 hp). When processing wood shavings, it will consume about 10-15 kW (13-20 hp), and efficiency losses are minimal. However, for large raw sawdust, almost the entire nominal power may be required. The most cost-effective and relatively reliable option is a product fan running at 2900 rpm with a working wheel diameter of 600 mm (24 inches) and a width of 120 mm (5 inches). To minimize costs, the fan is placed after the dryer, before the cyclone. This allows the cyclone to be utilized with air pressure and a minimal wall thickness. Sometimes, it is possible to modify a grain hammer mill to fit the required airflow, reducing the number of units, and delivering not only dry but also crushed material ready for pelleting. An additional advantage of crushing in a hot airflow is the preservation of high raw material temperatures, which significantly reduces the load on the pellet mill. The most suitable hammer mill for these purposes resembles a product fan, with a sieve mounted around the wheel. The ends of the blades have wear-resistant paddles that act as hammers. Such hammer mills are easily scalable and can be adjusted for different air throughput and pressure based on motor speed, wheel diameter, and width.