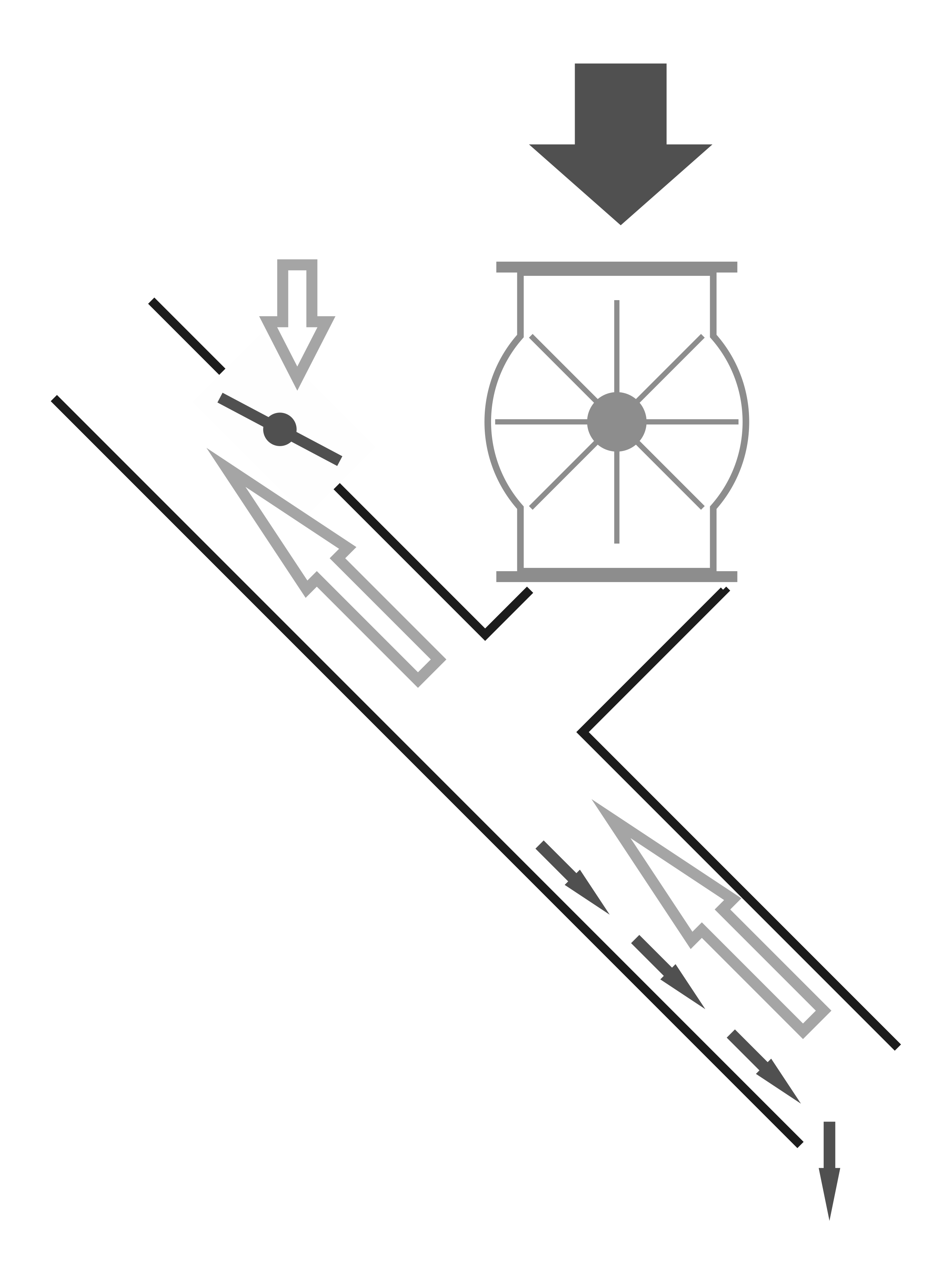

For separating stones and large pieces of wood, there is a simpler solution – separating them based on their floating ability in an airflow. Since the final grinding of dry raw material usually occurs in a large airflow, a special device called an aerodynamic separator is placed at the entrance to the hammer mill. Essentially, this is a rectangular air duct set at an angle of no less than 45° to the horizontal, with the ability to adjust air flow speed through it using a damper installed after the feed pipe along the flow direction. The material feed should be done through a lock hopper or screw to ensure smooth flow and prevent air from being sucked in. By adjusting the damper's position at the top, you can see that when fully open, even sawdust falls down, and when fully closed, stones pass into the hammer mill without delay. The operator selects the optimal position where the falling material contains traces of sawdust and small pieces of bark along with stones.

For separating stones and large pieces of wood, there is a simpler solution – separating them based on their floating ability in an airflow. Since the final grinding of dry raw material usually occurs in a large airflow, a special device called an aerodynamic separator is placed at the entrance to the hammer mill. Essentially, this is a rectangular air duct set at an angle of no less than 45° to the horizontal, with the ability to adjust air flow speed through it using a damper installed after the feed pipe along the flow direction. The material feed should be done through a lock hopper or screw to ensure smooth flow and prevent air from being sucked in. By adjusting the damper's position at the top, you can see that when fully open, even sawdust falls down, and when fully closed, stones pass into the hammer mill without delay. The operator selects the optimal position where the falling material contains traces of sawdust and small pieces of bark along with stones.

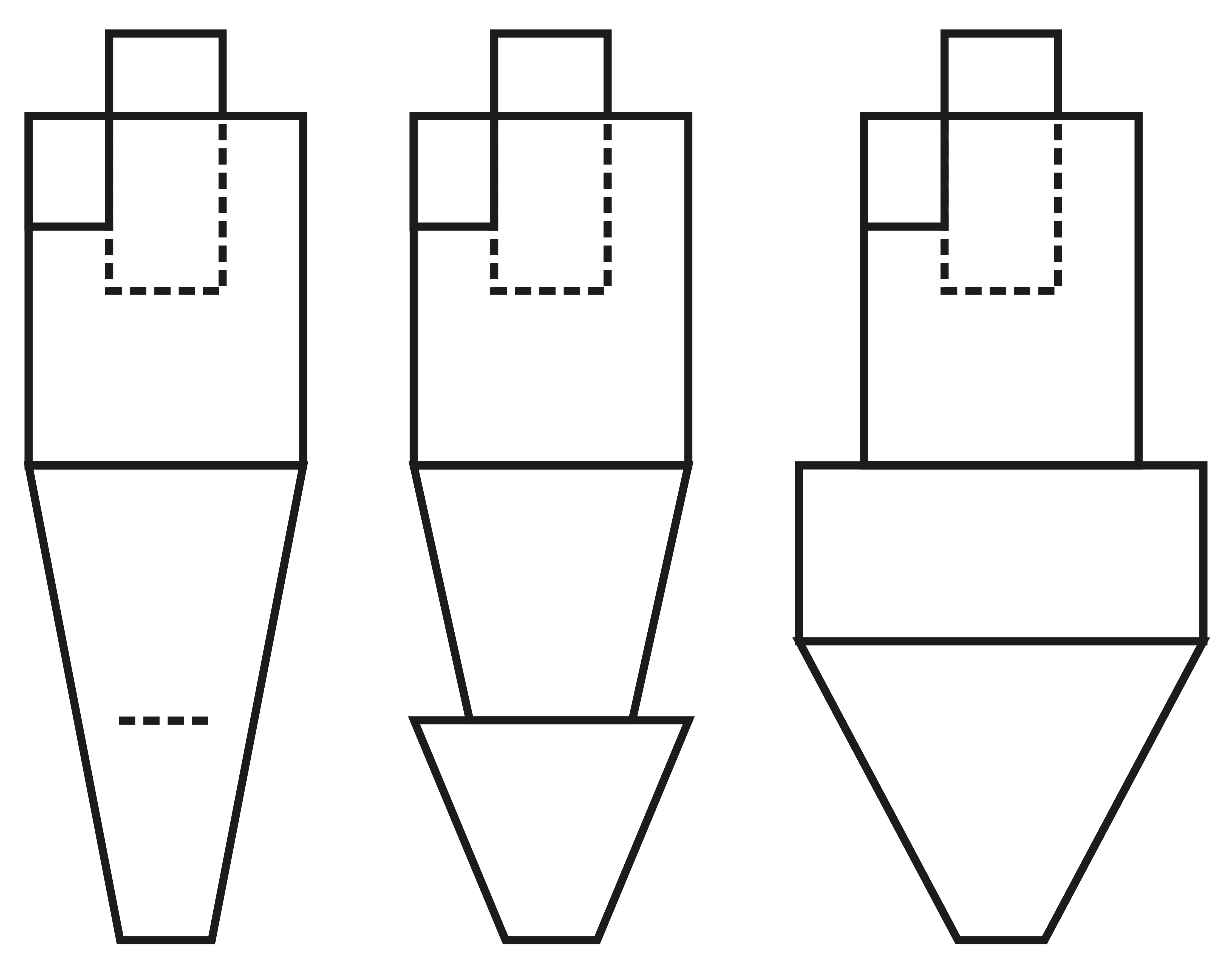

At the dryer drum's exit, a stone separator often is installed, consisting of a pipe with dampers. Large stones, brick fragments, and other large debris capable of lodging in air ducts or damaging the lock hopper roll into it. In operation, the upper damper is open, causing heavy impurities to accumulate on the lower damper. Although sawdust may pack between stones, it's mostly carried away by air vortices. For periodic clearing, the operator closes the top and opens the lower dampers. Due to continuous sawdust presence, such collectors are ineffective for gravel and crushed stone, and barely capture small pieces of bark.

At the dryer drum's exit, a stone separator often is installed, consisting of a pipe with dampers. Large stones, brick fragments, and other large debris capable of lodging in air ducts or damaging the lock hopper roll into it. In operation, the upper damper is open, causing heavy impurities to accumulate on the lower damper. Although sawdust may pack between stones, it's mostly carried away by air vortices. For periodic clearing, the operator closes the top and opens the lower dampers. Due to continuous sawdust presence, such collectors are ineffective for gravel and crushed stone, and barely capture small pieces of bark.

Sometimes these devices use only one damper, which, when briefly opened, allows stones to fall down while sawdust gets whisked away to the cyclone. This design minimizes raw material loss but presents two problems. First, sawdust carries away more small stones and may occasionally toss larger stones back into the air duct. Second, such air suction drastically reduces vacuum in the entire dryer and heat generator tract, possibly causing vacuum sensors to trigger an emergency mode. Due to these drawbacks, such stone separators are used on the cheapest, most basic dryers with wood-burning stoves.

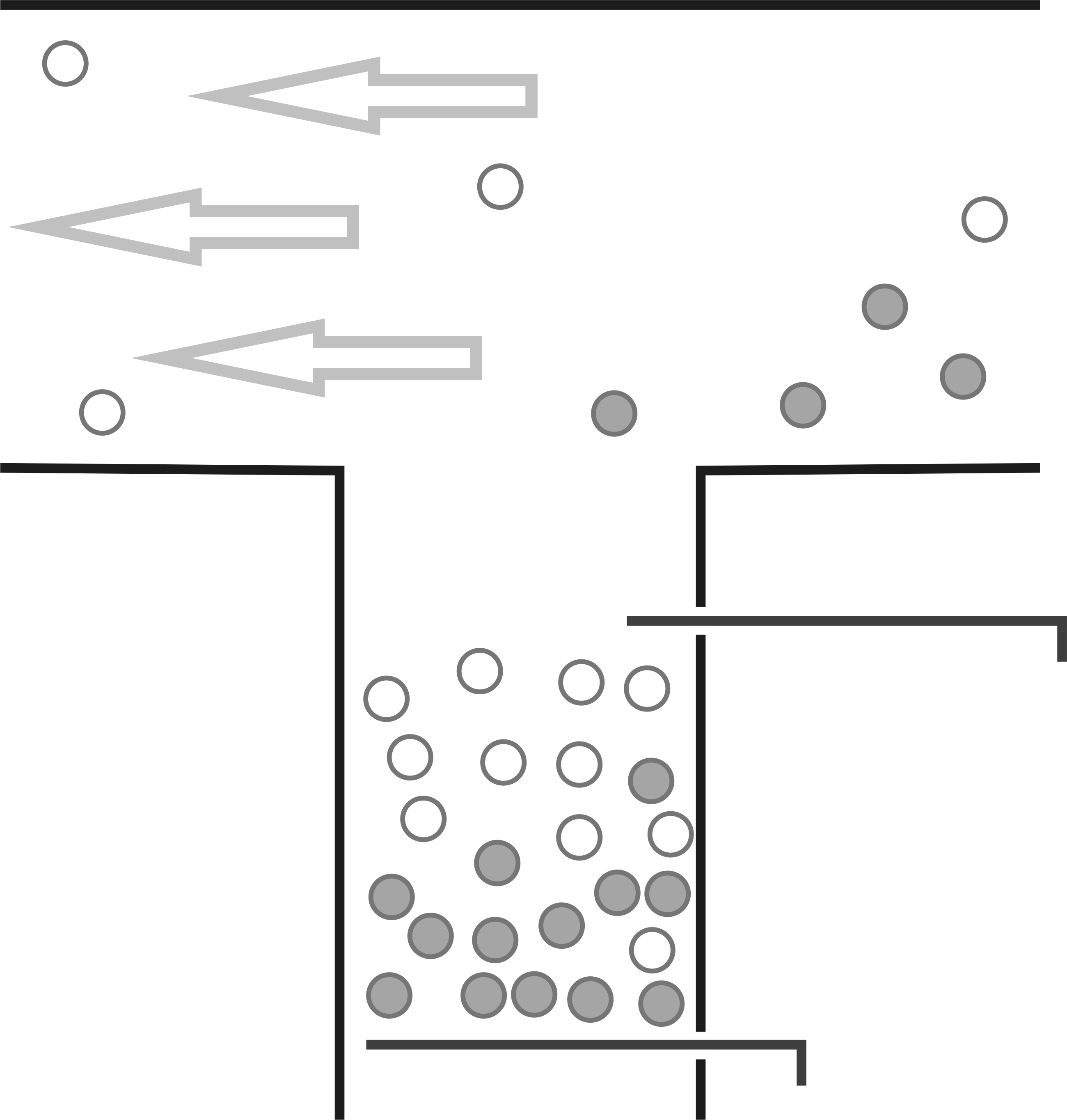

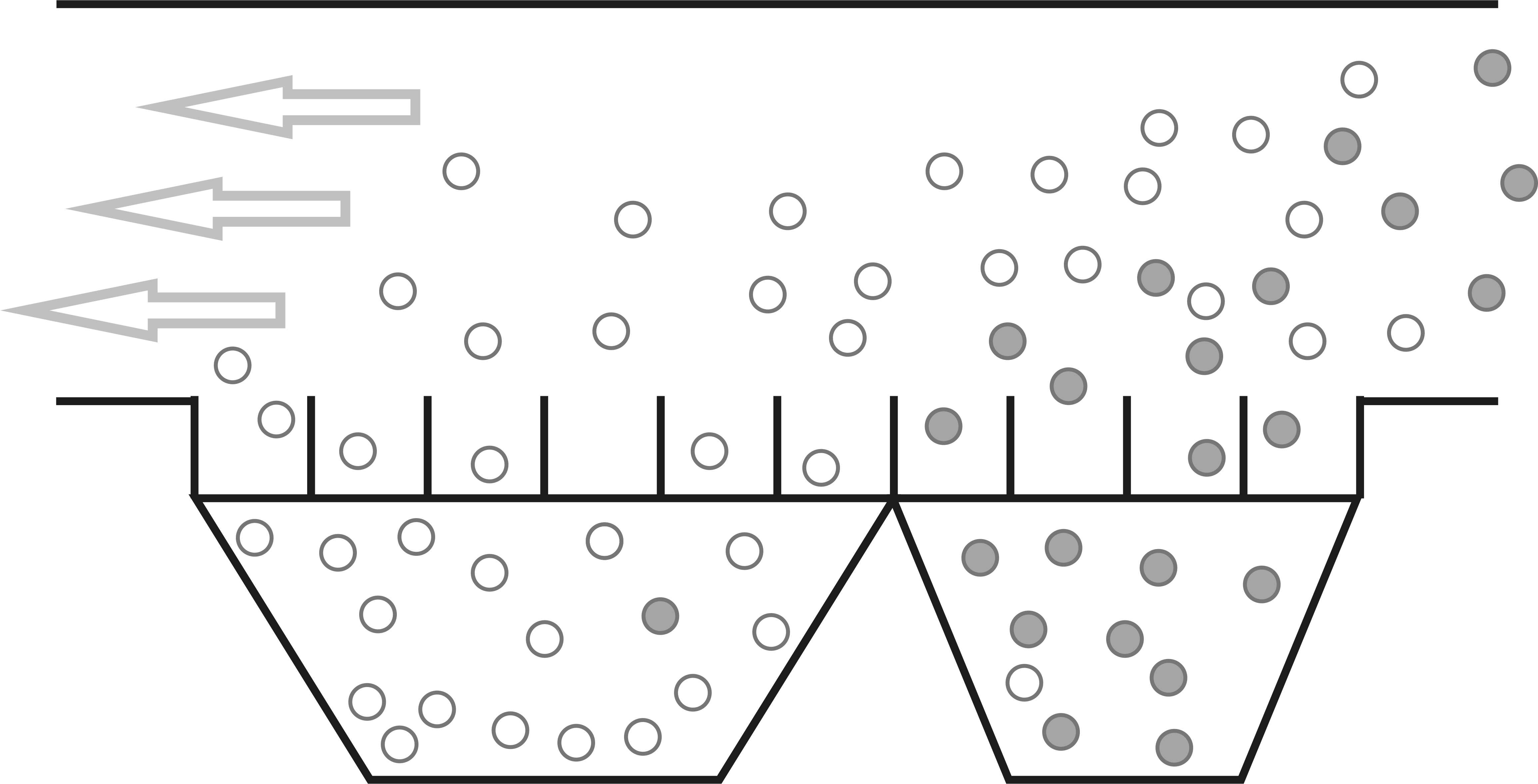

For aerodynamic raw material cleaning, separation chambers working like winnowing machines are sometimes proposed. Raw material is introduced in the horizontal airflow metered, and beneath the winnowing machine are compartments, each leading to separate collectors. The illustration shows a basic version, though there exists a variety of more complex systems worldwide, such as cyclone columns with vanes and louvers at different heights and angles.

For aerodynamic raw material cleaning, separation chambers working like winnowing machines are sometimes proposed. Raw material is introduced in the horizontal airflow metered, and beneath the winnowing machine are compartments, each leading to separate collectors. The illustration shows a basic version, though there exists a variety of more complex systems worldwide, such as cyclone columns with vanes and louvers at different heights and angles.

When the raw material and impurities have stable properties – predictable and slightly varying moisture, fraction, and density – winnowing machines can be tuned for effective operation. However, in biofuel production from wood waste, raw material moisture and impurity fraction vary widely, critically affecting particle floating speed. Thus, adjustments in raw material source equipment, weather fluctuations, and even loader operator experience will continuously require separator recalibration, risking material loss or accidents due to impurities.