The variety of fabrics used for filters is vast. Therefore, it's best to consult the manufacturer for all the details about using specific fabric. For a simple self-cleaning design, it's advisable to use very thin fabrics with fine and dense fibers. Thin material doesn't become overly rigid when packed with dust and tends to flutter under air currents, allowing the layers of wood dust to fall off easily. To prevent the dust layer from being pressed against the surface from inside, the airflow through the fabric should not exceed 0.15-0.2 m/s (0.49-0.66 ft/s). If the airflow is higher, even forced shaking quickly becomes ineffective, requiring work stoppage for cleaning. This is because the flow velocity through the fibers determines the particles' ability to penetrate and get stuck in the fabric rather than accumulate as a surface layer. Consequently, increased airflow also significantly shortens the lifespan of filter materials.

The variety of fabrics used for filters is vast. Therefore, it's best to consult the manufacturer for all the details about using specific fabric. For a simple self-cleaning design, it's advisable to use very thin fabrics with fine and dense fibers. Thin material doesn't become overly rigid when packed with dust and tends to flutter under air currents, allowing the layers of wood dust to fall off easily. To prevent the dust layer from being pressed against the surface from inside, the airflow through the fabric should not exceed 0.15-0.2 m/s (0.49-0.66 ft/s). If the airflow is higher, even forced shaking quickly becomes ineffective, requiring work stoppage for cleaning. This is because the flow velocity through the fibers determines the particles' ability to penetrate and get stuck in the fabric rather than accumulate as a surface layer. Consequently, increased airflow also significantly shortens the lifespan of filter materials.

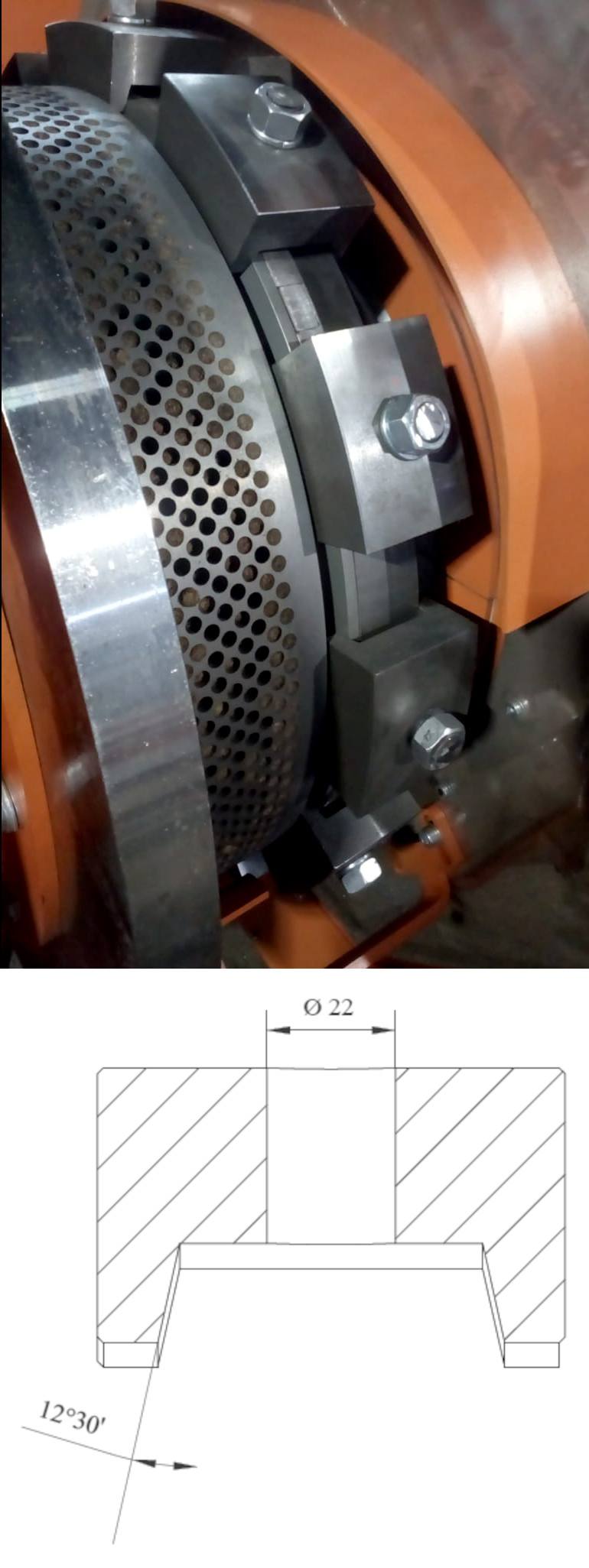

The simplest and most efficient design for an aspiration setup is vertical multi-bag filters, where the air is supplied to an upper box and dust collection occurs through the lower part into bags or is conveyed out through a screw conveyor with an airlock valve. The box and lower hoppers can be exposed to significant air pressure if the filters get clogged, necessitating reinforcements and stretchers along their walls. The effective filtration area usually increases proportionally with a decrease in bag diameter for the same installation dimensions. There is typically a 100 mm (4 inch) gap left between the ducts for ease of attaching their ends with clamps. Therefore, using a bag diameter smaller than 200 mm (8 inches) is not practical, as it increases the cost of the filters and complicates maintenance.

Considering the filters' tendency to ignite and explode quickly, they should be located away from the main equipment, or in a special annex to the workshop, with mandatory fire alarms. As mentioned in the section on buffer hoppers, clogged filters significantly increase air pressure inside cavities, and without separation by an airlock valve, they can lead to a sudden and uncontrolled release of material through the screw feeder. Moreover, a decrease in airflow speed leads to an increase in air temperature, raising the likelihood of the dusty air igniting and exploding. Therefore, for maximum safety, it is strongly recommended to equip filtration installations with both temperature sensors and a spark detection system. The control automation should include inputs for signals that automatically shut down the equipment.

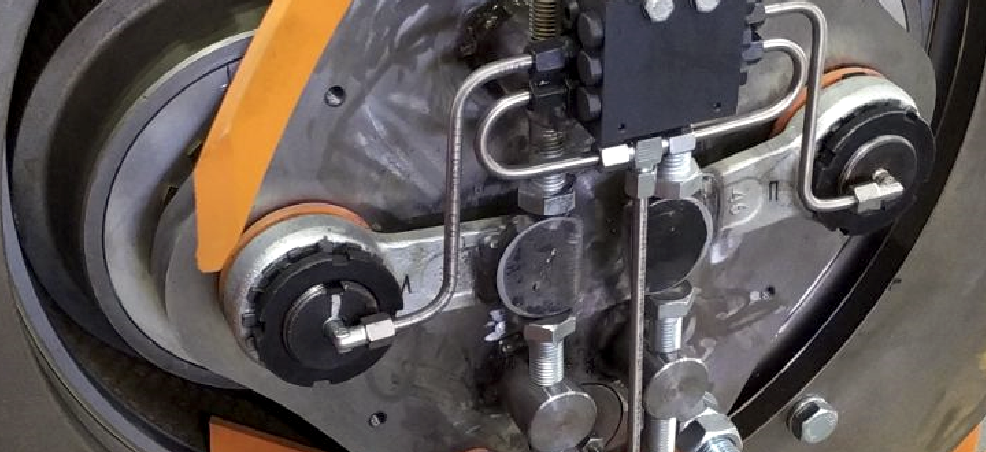

The most expensive version of multi-bag filters includes pneumatic nozzles that direct airflow down into each bag through the cover. The nozzles are grouped according to the number of rows into several pneumatic tubes, each equipped with an electric valve. Air is supplied sequentially to the tubes at a pressure of 6-8 bar (87-116 psi) for 0.5 seconds at intervals of 10-30 minutes. This assists in dislodging the accumulated dust.