Automated Bag Palletizer

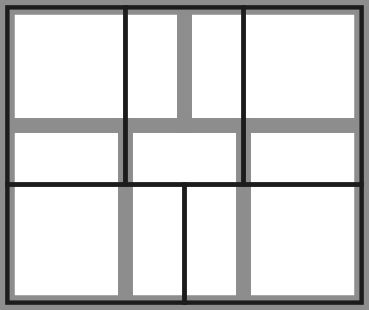

Typically, bags are arranged on a pallet with five in one layer: three in a row, and two across. The next layer is placed in the same manner, but rotated 180 degrees. This resembles brickwork, where each bag is secured between four others, providing stable stacking with a total weight on the pallet of up to 1-1.5 tonnes (2200-3300 pounds). Manual stacking is quite labor-intensive and heavily reliant on the human factor. Early in the shift, the worker might adjust a slightly misaligned bag, but later on, such mistakes might go unnoticed. As a result, in a truckload of two dozen pallets, at least one might fall apart during transportation, damaging the packaging. This considerably increases the unloading time, raises the costs due to loss of product appearance, and can even lead to traffic accidents.

Typically, bags are arranged on a pallet with five in one layer: three in a row, and two across. The next layer is placed in the same manner, but rotated 180 degrees. This resembles brickwork, where each bag is secured between four others, providing stable stacking with a total weight on the pallet of up to 1-1.5 tonnes (2200-3300 pounds). Manual stacking is quite labor-intensive and heavily reliant on the human factor. Early in the shift, the worker might adjust a slightly misaligned bag, but later on, such mistakes might go unnoticed. As a result, in a truckload of two dozen pallets, at least one might fall apart during transportation, damaging the packaging. This considerably increases the unloading time, raises the costs due to loss of product appearance, and can even lead to traffic accidents.

Relatively simple to install and program but expensive, automatic palletizers were manufactured based on the KUKA arm. Since bags weighing 15 kg (33 pounds) are quite heavy for servo motors, medium and senior models of manipulators had to be used. This was justified in the production of relatively expensive feed with high factory throughput, especially in regions with high labor costs.

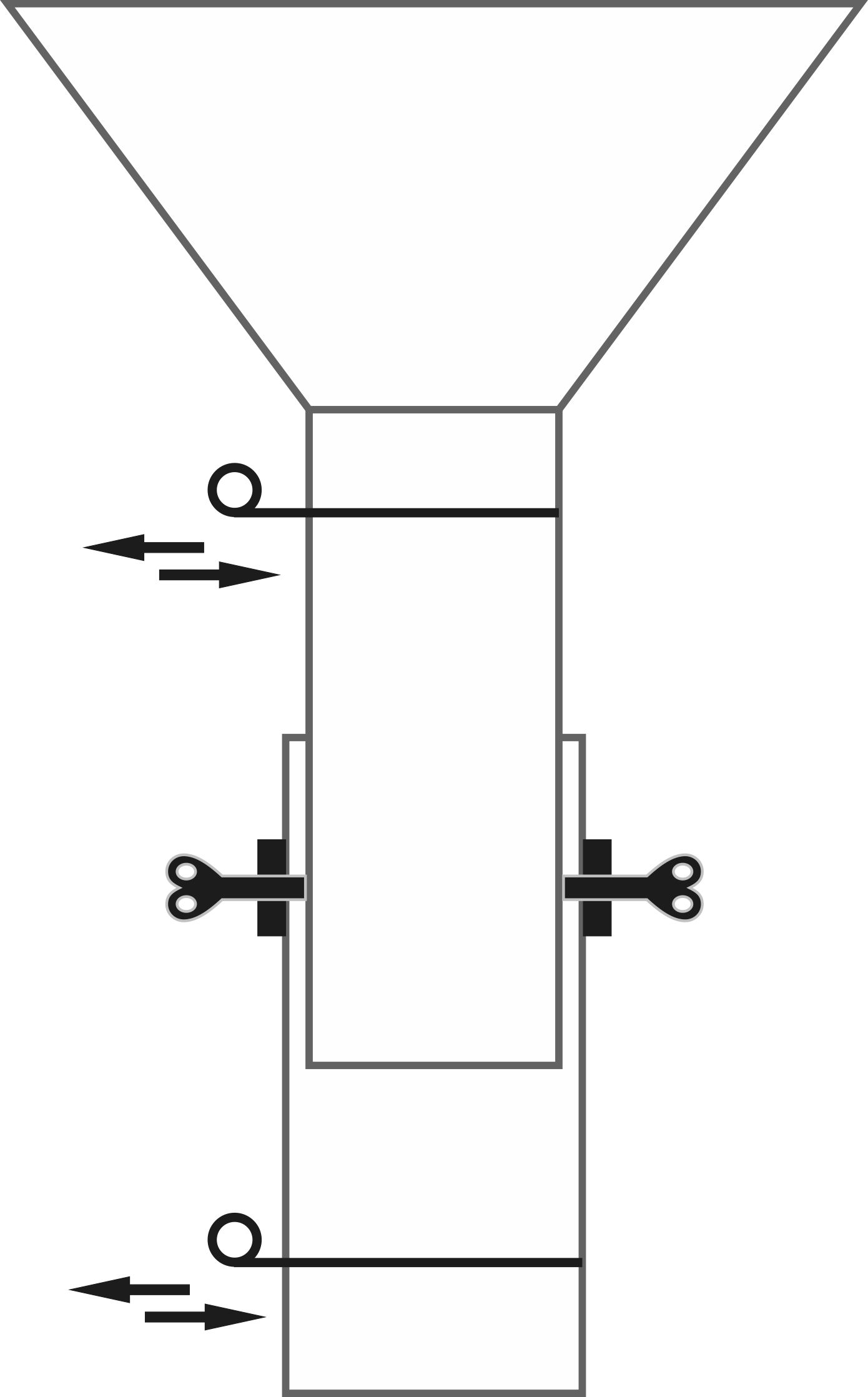

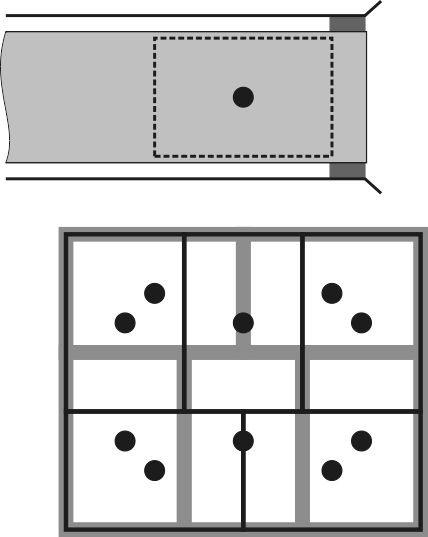

More widely used are automatic palletizers with narrow specialization and simple construction. The manipulator moves in two coordinates across the plane, effectively having eleven destination points. As seen in the diagram, it only has five positions along one coordinate, and five along the other, including the pick-up point from the belt conveyor. Such a trajectory can be managed with simple automation, focused on step-by-step actions. Pneumatic drives are used for bag gripping and 90-degree rotation. The table with the pallet is suspended on powered chains with mechanisms used for forklifts. Initially, the table is raised as close as possible to the manipulator, then lowered after each layer is stacked. The height for each layer can be set using inductive sensors acting as limit switches, reacting to the table edge, interacting with the drives through basic programmable relays. Thus, powerful stepper motors and computer visualization are avoided, and components for the device are cheap and widely available. Such an automated palletizer pays for itself within the first year, is durable, and highly repairable.

More widely used are automatic palletizers with narrow specialization and simple construction. The manipulator moves in two coordinates across the plane, effectively having eleven destination points. As seen in the diagram, it only has five positions along one coordinate, and five along the other, including the pick-up point from the belt conveyor. Such a trajectory can be managed with simple automation, focused on step-by-step actions. Pneumatic drives are used for bag gripping and 90-degree rotation. The table with the pallet is suspended on powered chains with mechanisms used for forklifts. Initially, the table is raised as close as possible to the manipulator, then lowered after each layer is stacked. The height for each layer can be set using inductive sensors acting as limit switches, reacting to the table edge, interacting with the drives through basic programmable relays. Thus, powerful stepper motors and computer visualization are avoided, and components for the device are cheap and widely available. Such an automated palletizer pays for itself within the first year, is durable, and highly repairable.

Automated Pallet Stretch Wrapper

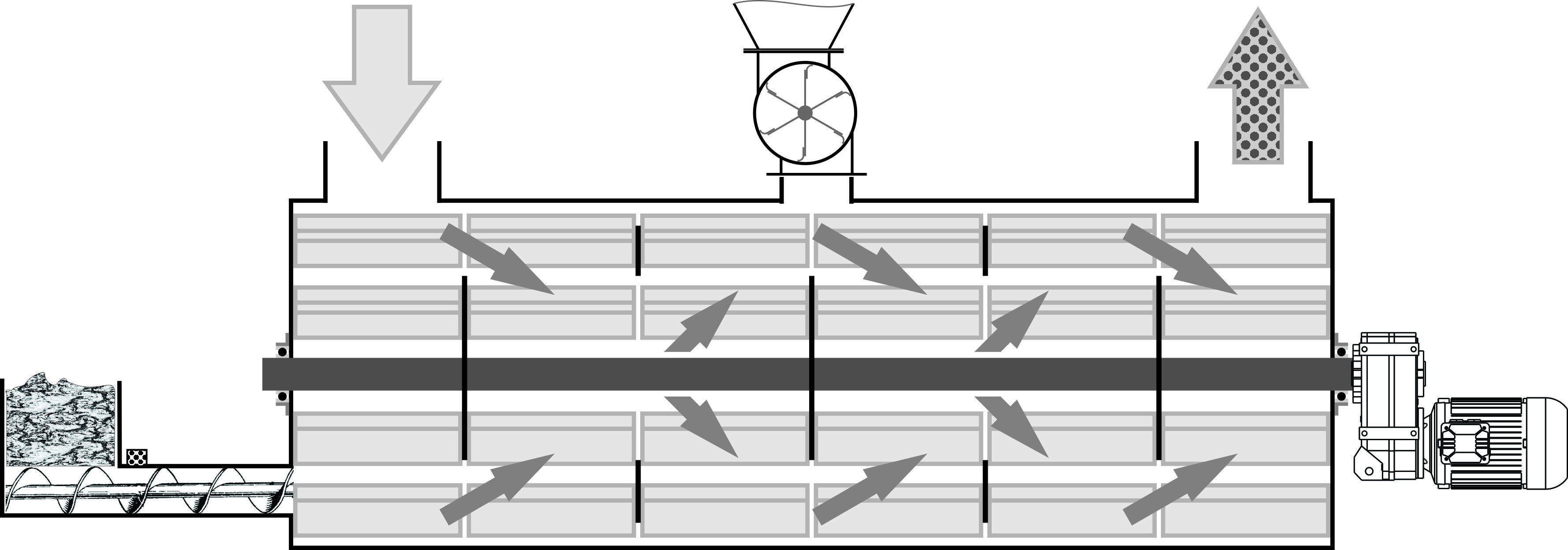

Although thermal shrink film has long been used in the industry to protect goods on pallets from precipitation and provide stability to stacked boxes and bags during transport, biofuel production sites generally do not have such high throughput to bother with automatic sleeve applicators and heating ovens. There is a manual packaging technology using a cover sheet on top and stretch film wrapping. This procedure is quite feasible manually, but there are nuances.

Manual wrapping is usually done with fairly small household rolls, where the film costs 10-30% more per running meter than in industrial rolls weighing 20-30 kg (44-66 pounds). It is physically impossible for most people to use industrial rolls for manual wrapping due to their weight. The interest in the automatic wrapper is not in these percentages. This is because it is possible to adjust the tension on it, so the film consumption can be reduced by two or three times. The ability to stretch without losing strength is particularly evident at temperatures above 20°C (68°F), so the wrapper should be kept in a heated area. If you compare this savings with the cost of the automatic wrapper, it pays for itself within half a year at a price of 3-5 thousand dollars.

Manual wrapping is usually done with fairly small household rolls, where the film costs 10-30% more per running meter than in industrial rolls weighing 20-30 kg (44-66 pounds). It is physically impossible for most people to use industrial rolls for manual wrapping due to their weight. The interest in the automatic wrapper is not in these percentages. This is because it is possible to adjust the tension on it, so the film consumption can be reduced by two or three times. The ability to stretch without losing strength is particularly evident at temperatures above 20°C (68°F), so the wrapper should be kept in a heated area. If you compare this savings with the cost of the automatic wrapper, it pays for itself within half a year at a price of 3-5 thousand dollars.

The maximum tension of the stretch film is limited not only by its ability to suddenly tear from the roll but also by the unevenness of the wrapped surface of the pile of bags. Protruding parts locally increase the load and lead to film tearing, especially at the protruding corners of the bags. Therefore, the bag corner folding device on the automatic packer plays a crucial role in the reliability of the wrapping and the saving of stretch film. This device is usually offered as an option with the packer and costs about 100 dollars without any complications in pneumatics and control automation.