Semi-automatic packaging involves using pre-made bags where dosing occurs automatically, while bag placement and removal are done manually. Often, a belt conveyor is installed under the packaging machine, where the bag with pellets is lowered after filling. Along the sides of the conveyor, guides hold the bag upright, and a bag closing machine or sealer is used at the end of the guides. After sealing, a second worker picks up the bag and places it on a pallet. With relatively inexpensive labor and throughput of up to 1 tonne per hour, semi-automatic packaging is quite justified, as the set of machines and equipment costs around 10,000 dollars and requires no complex setup or maintenance.

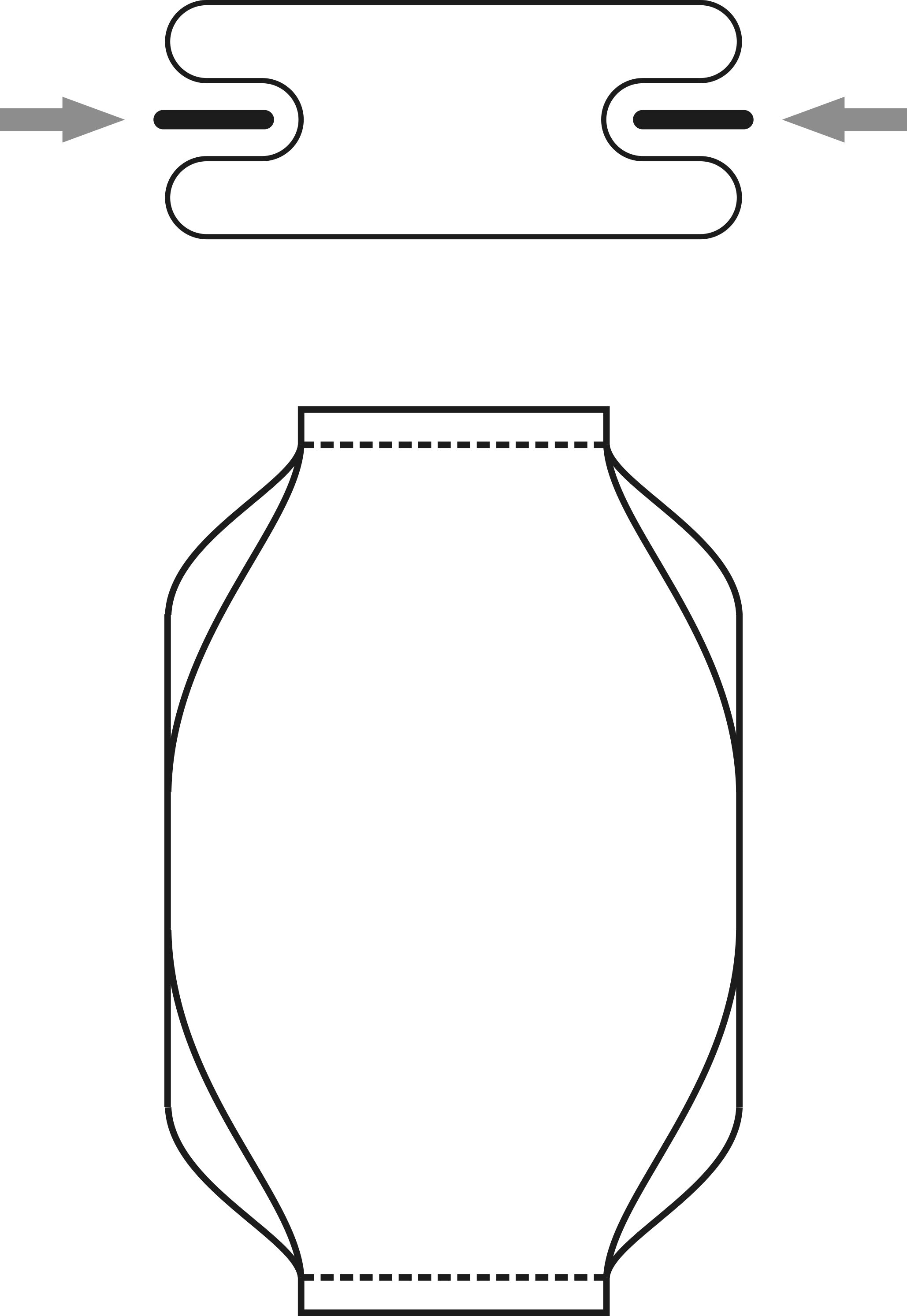

In automatic packaging, bags are formed from a roll-fed film. Typically, polyethylene film is used, which is rolled into a tube and sealed along the seam by hot rollers continuously. As a result, at any moment, the tube is sealed at the bottom, creating a bag with an open top that transitions through guide rollers into the fed film. Through the top, doses of pellets are rhythmically dispensed, and the bag is sealed with a simultaneous cut in the middle of the strip, which simultaneously closes the bottom bag and forms the top of the upper bag. To speed up the process, three feeders are often used, which alternately measure doses into intermediate containers, opening into a single funnel above the bag.

The operating temperatures of sealing rollers and cutters should be considered when choosing material. Otherwise, trying to save on packaging might require holding excessively high temperatures and longer sealing times to properly weld edges, reducing overall productivity and reliability. Also, consider that using an additional device that folds corners inward increases the thickness of the material being sealed threefold. Therefore, the heater's power and the ability to transfer this heat to the unit area at the contact point must also proportionally increase.

The operating temperatures of sealing rollers and cutters should be considered when choosing material. Otherwise, trying to save on packaging might require holding excessively high temperatures and longer sealing times to properly weld edges, reducing overall productivity and reliability. Also, consider that using an additional device that folds corners inward increases the thickness of the material being sealed threefold. Therefore, the heater's power and the ability to transfer this heat to the unit area at the contact point must also proportionally increase.

Since pneumatic drives are the most reliable and fastest for the mechanisms of a packaging machine, it is essential to plan not only a compressor with sufficient capacity but also a receiver with an air drying and filtration system. This ensures stable operation and long service life under dusty and low-temperature conditions in the workshop.

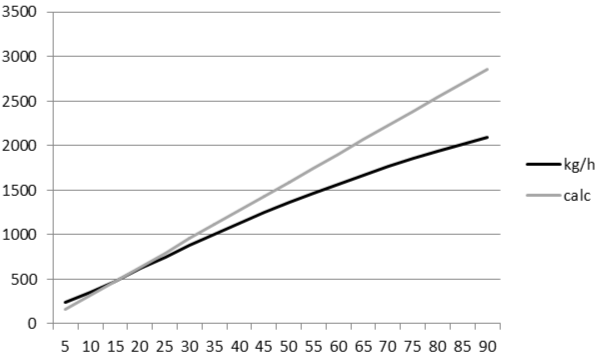

Automatic packaging achieves quick payback with 24-hour operation at a pellet mill production rate of 1 tonne per hour or with single-shift work at a production rate of 2-3 tonnes per hour. The maximum output of the smaller models is usually limited to 4-5 tonnes per hour, mainly depending on the number of feeders and their filling speed.