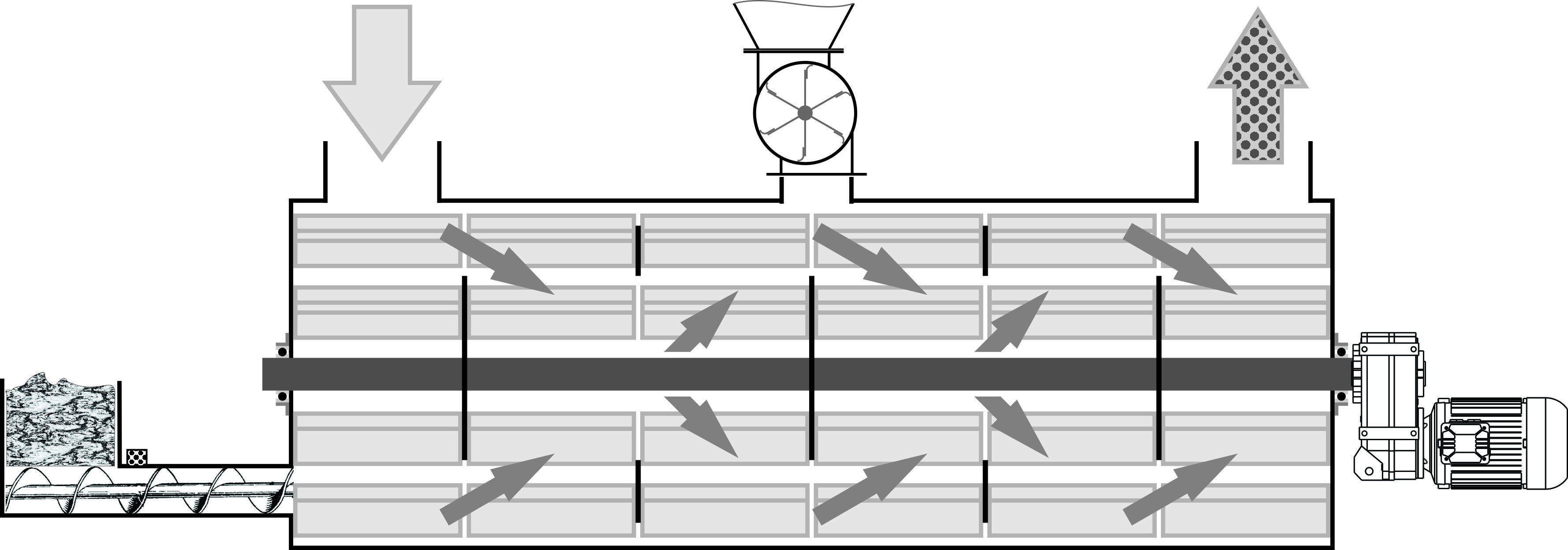

This is the most affordable and common type of conveyor used in various industries, primarily for bulk materials ranging from sawdust to large chunks of rock. It's also used to remove semi-liquid manure from under bird and animal cages. The construction is based on two drums: a tension drum and a drive drum, with intermediate rollers installed at equal intervals between them. A rubber belt typically moves over these rollers. To prevent spillage over the edge, monolithic chevron-shaped protrusions and multiple rows of intermediate rollers are used to create a trough in the middle of the belt.

The belt is usually joined by stitching if regular longitudinal bends occur in operation, with the common issue being the tearing of the lock at the edges. Typically, such tears occur due to regular contact of the belt edge with the structure. A well-centered belt in an empty state starts to sway significantly when material is fed, especially with significant temperature differences. In the early hours and days, personnel actively combat this by trying to adjust the belt position on the go, installing guide rollers, slides, and distributing the load, but eventually accept it as an inevitable problem and simply regularly repair and replace the belt.

The belt is usually joined by stitching if regular longitudinal bends occur in operation, with the common issue being the tearing of the lock at the edges. Typically, such tears occur due to regular contact of the belt edge with the structure. A well-centered belt in an empty state starts to sway significantly when material is fed, especially with significant temperature differences. In the early hours and days, personnel actively combat this by trying to adjust the belt position on the go, installing guide rollers, slides, and distributing the load, but eventually accept it as an inevitable problem and simply regularly repair and replace the belt.

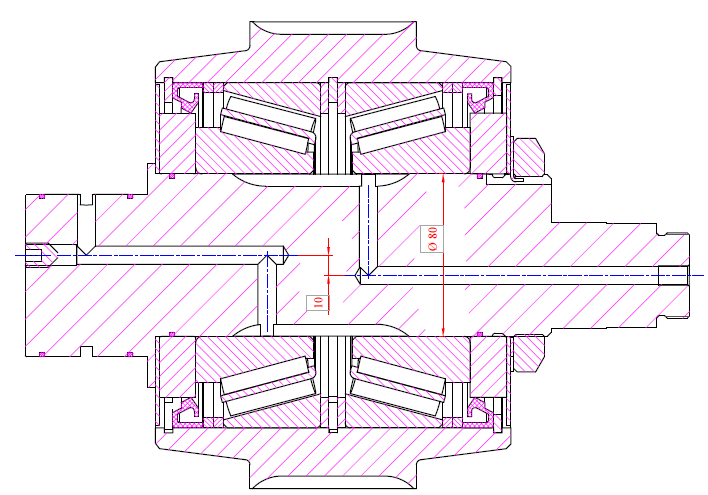

On some conveyors, a once-adjusted belt operates for years without heightened attention. The secret lies in the correct drum shape: oval. This solution has been used for many centuries in flat belt drives. With such a shape, the belt continuously sways sideways but with a very small amplitude. When slightly shifting to one side, the belt slightly tilts and "steers" itself back to the center. The barrel-shaped drums are well noticeable on conveyors with narrow belts and high feed speeds but work with any belt width and drum length. Usually, to create the necessary effect, a difference in drum radius of about half the belt thickness between the center and the edge is sufficient. Greater curvature complicates adjustment and increases belt wear due to a reduced surface contact area.

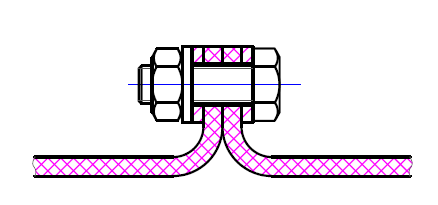

If the conveyor is not very long and the belt runs without forming a trough with support intermediate rollers, it is much easier to join its ends with a simple lock made of two plates, directing the belt ends outward. This connection mimics a scoop and is often practiced for belt scraper conveyors with corrugated sides. The hole spacing is usually from 30 to 50 mm (1.2 to 2 inches), and the diameter is from 8 to 12 mm (0.3 to 0.5 inches). These parameters are determined by the required strength of the connection, the stiffness of the applied plates, and the maximum lock sizes. If the drums are oval, the lock should be made from 3 to 5 parts, leaving gaps of 3 to 5 mm (0.1 to 0.2 inches) between them.

If the conveyor is not very long and the belt runs without forming a trough with support intermediate rollers, it is much easier to join its ends with a simple lock made of two plates, directing the belt ends outward. This connection mimics a scoop and is often practiced for belt scraper conveyors with corrugated sides. The hole spacing is usually from 30 to 50 mm (1.2 to 2 inches), and the diameter is from 8 to 12 mm (0.3 to 0.5 inches). These parameters are determined by the required strength of the connection, the stiffness of the applied plates, and the maximum lock sizes. If the drums are oval, the lock should be made from 3 to 5 parts, leaving gaps of 3 to 5 mm (0.1 to 0.2 inches) between them.