1. Initial Calculation and Equipment of Pelletizing Line

2. Raw Material Reception and Storage

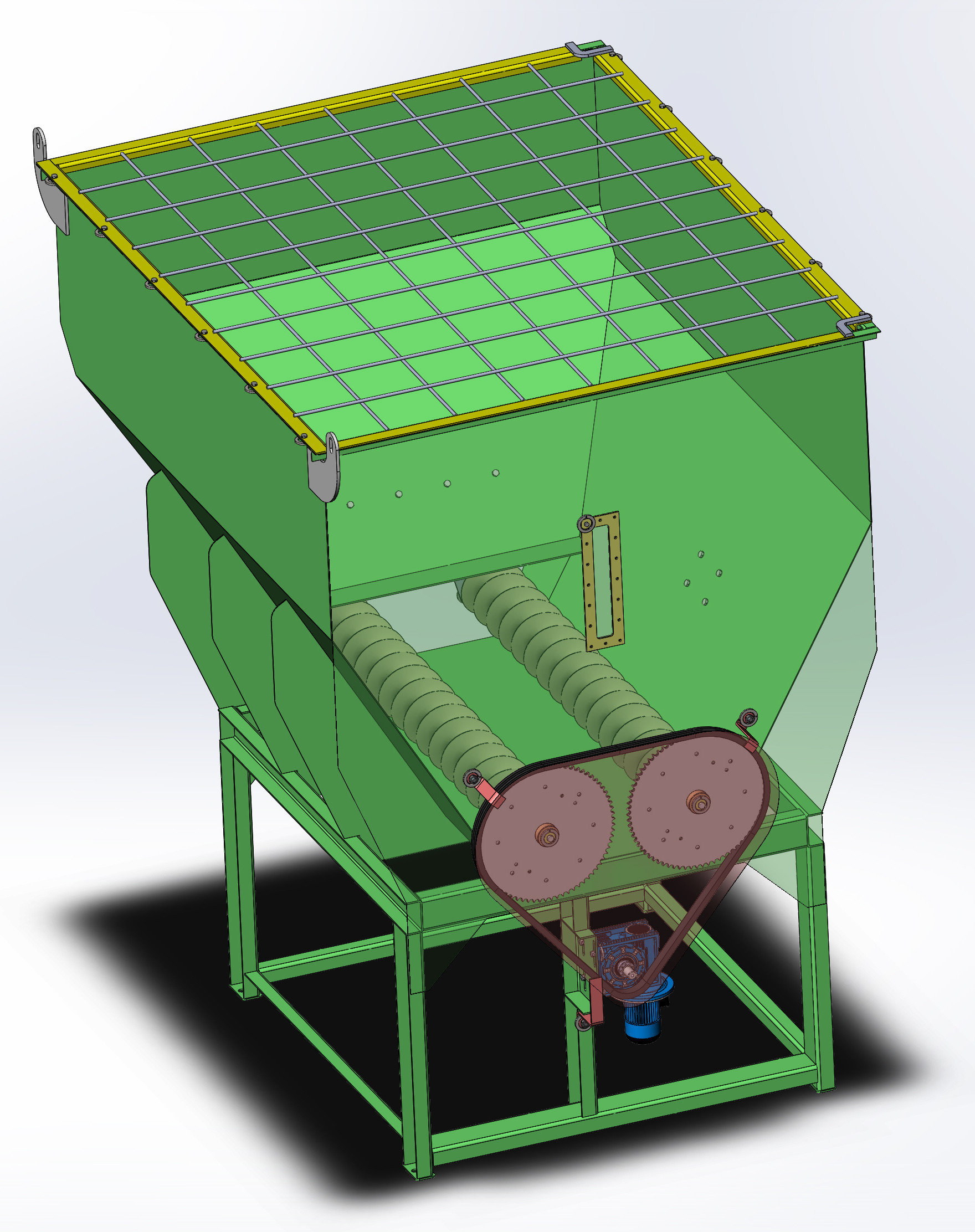

2.4. Types of Automatic Storage and Raw Material Feeding Hoppers

3. Raw Material Grinding

3.1. Primary Raw Material Grinding

3.4. Screenless Mills

4. Raw Material Handling

4.4. Bucket Elevators

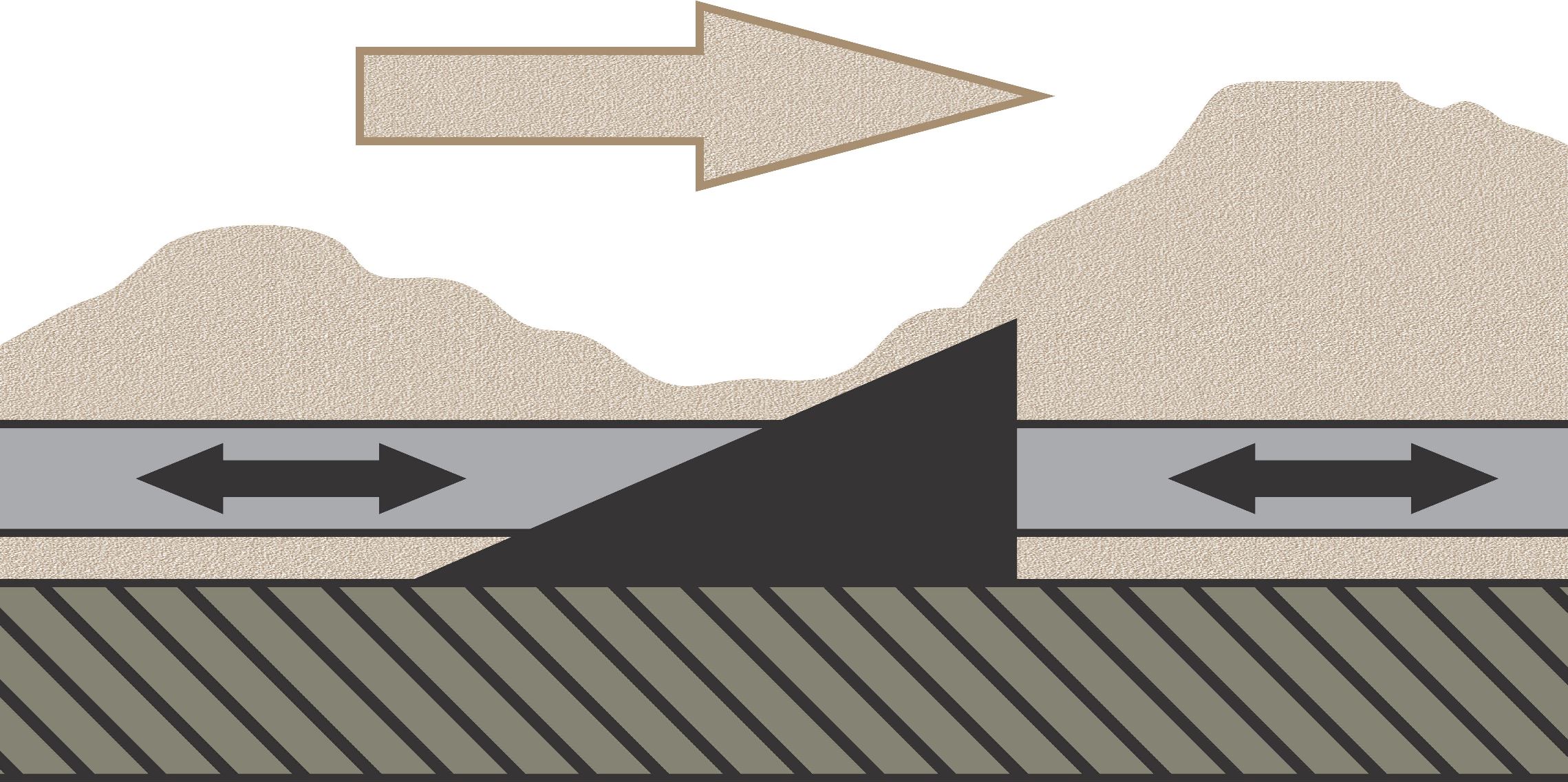

4.5. Screw Conveyors

4.6. Pneumatic Transport

4.7. Vibrating Conveyors

5.1. Wood Debarking

5.4. Disc Separator

5.6. Liquid Separation

6. Heat Generation

7. Types of Biomass Dryers

7.2. Types of Drum Dryer

7.3. Rotary Dryers with Stationary Body

7.4. Conveyor Dryer

7.5. Screw Dryer

7.6. Aerodynamic Dryer

7.7. Heat Agent Recovery

8. Pelletizing

8.2. Types of Pellet Mills Based on Press Unit Design

8.3. Mechanics of the Pelletizing Process

8.4. Press Unit Design in Detail

8.5. Types of Pellet Mills by Drive System

10. Raw Material Moistening

10.1. Moisture of Raw Material

11. Cooling and Stabilization of Pellets

11.2. Types of Coolers and Operating Principle

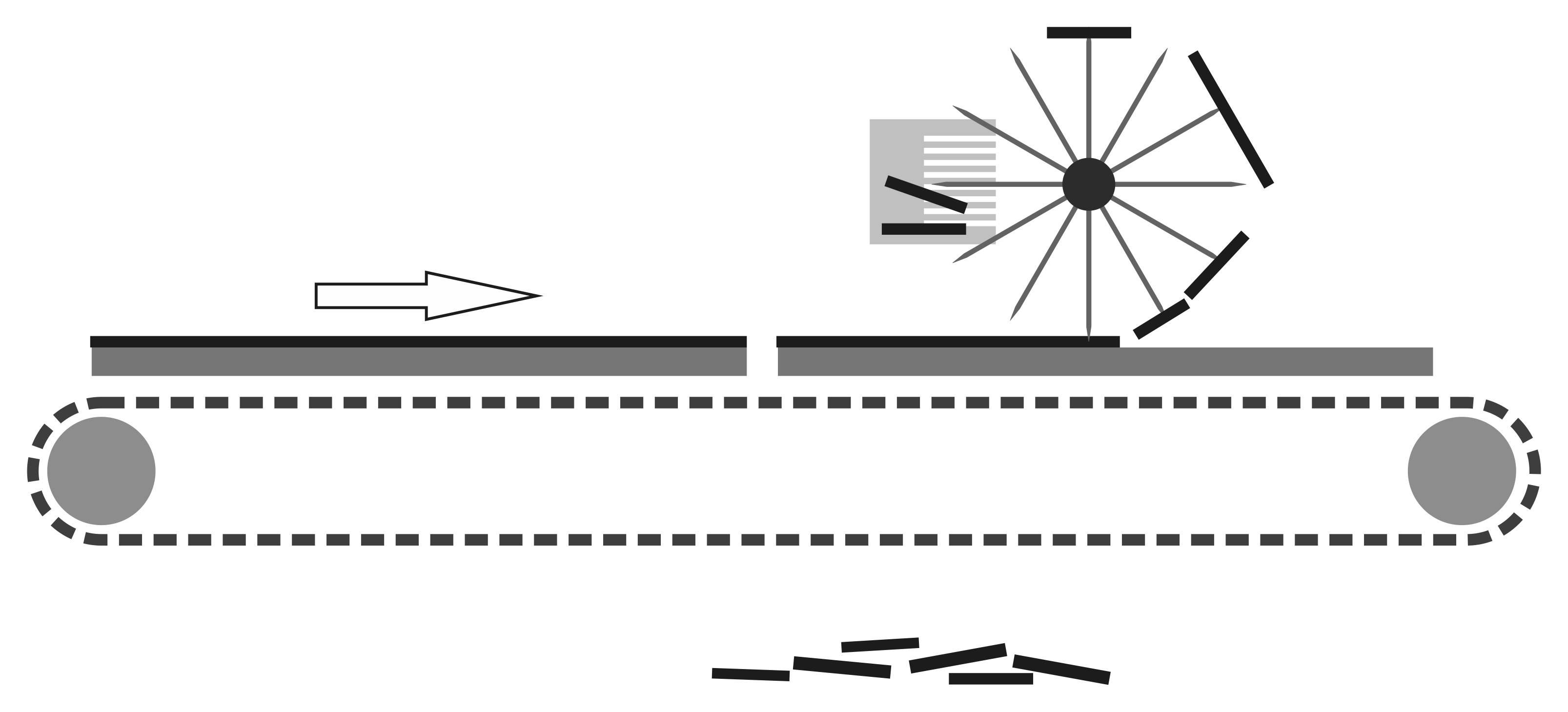

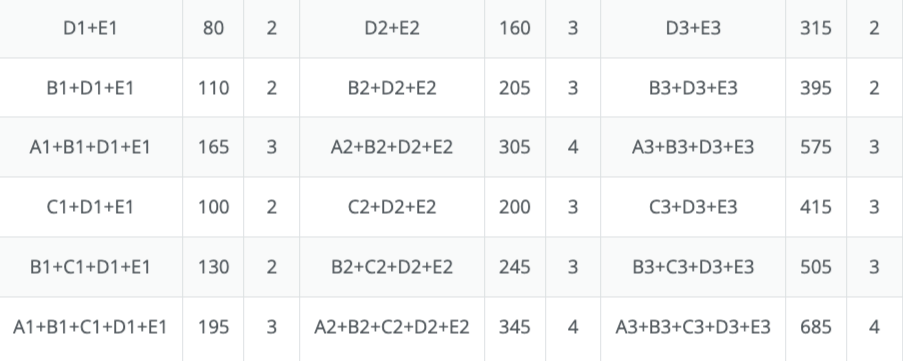

11.3. Fines Collection

12. Packaging and Storage

12.1. Pellet Dosing Methods

13. Line Layout, Economic Aspects, and Optimization

13.2. Specification Collection

14. Commissioning

14.1. Pellet Line Setup

14.2. Starting a Pellet Plant

16. Pellet FAQ