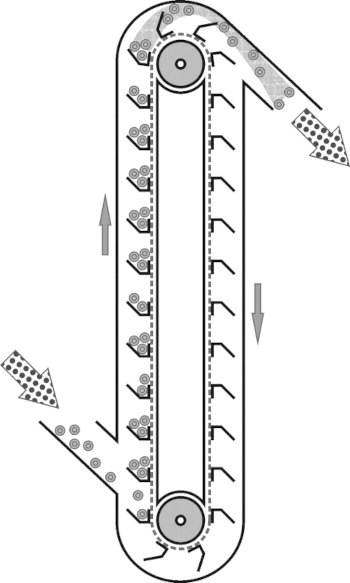

Bucket elevators have proven their efficiency for vertically transporting grains, pellets, and other types of dry bulk materials that do not tend to stick. The equipment boasts a fairly high efficiency because the working components experience minimal sliding friction over large surfaces, unlike with belt-scraper and chain conveyors. Another advantage is the saving of production floor space due to the compact installation. Elevating materials to a significant height and placing equipment on multiple floors can cut the total number of necessary conveyors, as well as the cost of the building and overall project, by two to three times.

Bucket elevators have proven their efficiency for vertically transporting grains, pellets, and other types of dry bulk materials that do not tend to stick. The equipment boasts a fairly high efficiency because the working components experience minimal sliding friction over large surfaces, unlike with belt-scraper and chain conveyors. Another advantage is the saving of production floor space due to the compact installation. Elevating materials to a significant height and placing equipment on multiple floors can cut the total number of necessary conveyors, as well as the cost of the building and overall project, by two to three times.

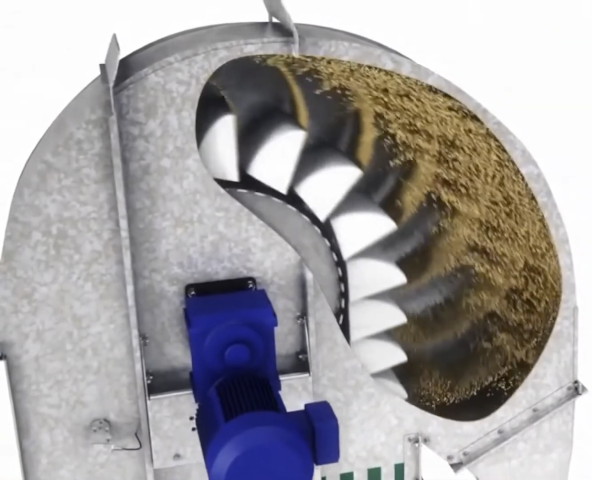

The bucket elevator is a vertical conveyor, based on a flat belt transmission. The width of the belt is significantly less than the diameter of the tension and drive wheels. Rubber belts have attached buckets, usually made from durable, wear-resistant plastic or aluminum. In the past, stamped steel blanks were used for this purpose. The wheels have a barrel-shaped surface, and in vertical shafts, the buckets move quite freely so belt centering is typically not an issue. There are also versions with conveyor chains, but these are much more expensive because of the need for large diameter sprockets and are less productive due to lower speed. When material enters through the inlet spout, it may spill beyond the bucket, but this is compensated by the elevator's ability to scoop everything from the lower tension area for self-cleaning. The tension wheel is spring-loaded, so a small amount of material under the belt generally does not cause damage or stoppage. Even a small amount of moisture-laden wood dust that adheres to the wheel does not remain long, as fragments of pellets soon follow and scrub off the residue.

Wheels with a design resembling a squirrel cage, where the outer surface is welded from rods that are then machined on a lathe, also possess good self-cleaning properties. If slats are used instead, accurately cut either on a guillotine or CNC laser, lathing is not necessary, and any burrs and sharp edges can be removed with any abrasive tool. If the wheels are mistakenly made with a cylindrical shape, flanges are welded to the sides as a temporary fix to prevent the belt from slipping sideways. This solution only temporarily alleviates the issue, causing heavy wear on both the belt edges and the flanges.

Wheels with a design resembling a squirrel cage, where the outer surface is welded from rods that are then machined on a lathe, also possess good self-cleaning properties. If slats are used instead, accurately cut either on a guillotine or CNC laser, lathing is not necessary, and any burrs and sharp edges can be removed with any abrasive tool. If the wheels are mistakenly made with a cylindrical shape, flanges are welded to the sides as a temporary fix to prevent the belt from slipping sideways. This solution only temporarily alleviates the issue, causing heavy wear on both the belt edges and the flanges.

The seemingly simple buckets have a triangular cross-section for good reason. During unloading, the material strikes the inclined surface of the lower bucket, directing most of it into the discharge chute. Sometimes, special lips are added to the side surface to reduce spillage, which is justified for slower-moving versions.

The seemingly simple buckets have a triangular cross-section for good reason. During unloading, the material strikes the inclined surface of the lower bucket, directing most of it into the discharge chute. Sometimes, special lips are added to the side surface to reduce spillage, which is justified for slower-moving versions.

In any case, the frequency of bucket installation should be sufficient so that each bucket is fully unloaded before the lower one descends into the shaft, helping to direct the material to the exit by blocking the gap. This explains the significant height and smooth slope in the upper drive section. Certainly, it is possible to select a speed and wheel diameter that would project the material at an almost horizontal acceleration, but this leads to a loss of seed viability and a sharp increase in the amount of fine fraction in the pellets. In a correctly calculated bucket elevator, the material is thrown from the bucket at the minimally necessary speed towards the exit, not spilled over the edge. This achieves a compromise between guaranteed discharge and the absence of spillage in the descending shaft.

In any case, the frequency of bucket installation should be sufficient so that each bucket is fully unloaded before the lower one descends into the shaft, helping to direct the material to the exit by blocking the gap. This explains the significant height and smooth slope in the upper drive section. Certainly, it is possible to select a speed and wheel diameter that would project the material at an almost horizontal acceleration, but this leads to a loss of seed viability and a sharp increase in the amount of fine fraction in the pellets. In a correctly calculated bucket elevator, the material is thrown from the bucket at the minimally necessary speed towards the exit, not spilled over the edge. This achieves a compromise between guaranteed discharge and the absence of spillage in the descending shaft.

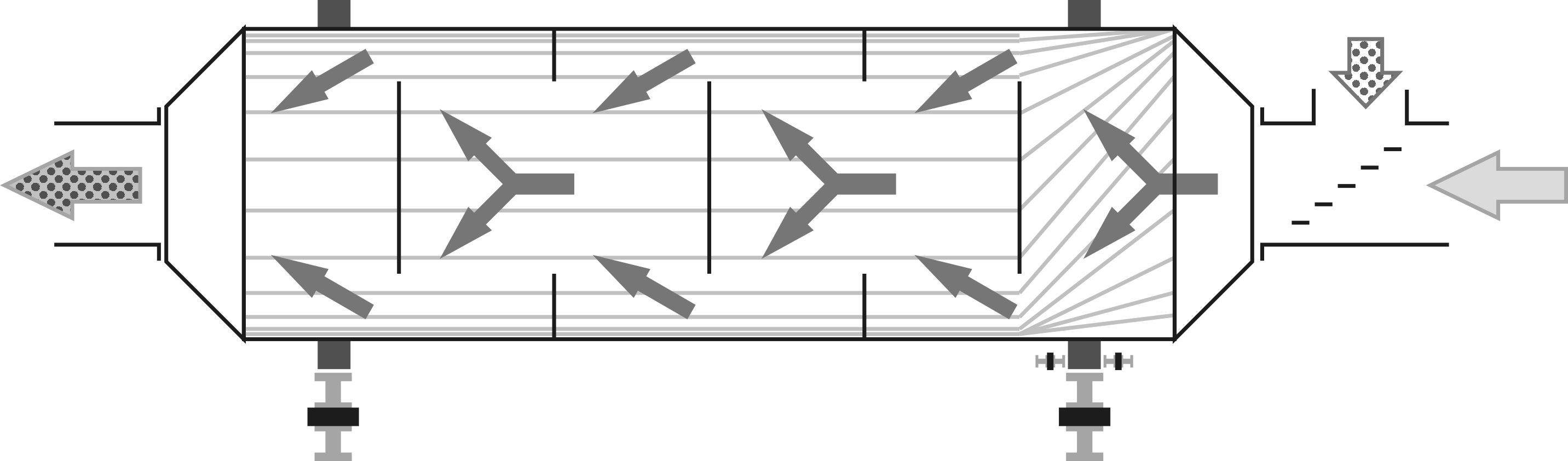

The main drawback of a bucket elevator is the limited access to the belt inside the shafts, as well as the difficulty in cleaning and inspecting inside the tension and drive sections. When transporting hot pellets, dust settles with condensate into a dense layer and may later detach in pieces, jamming the belt and leading to bucket tears and breaks at the attachment points. This issue is fairly successfully compensated by active ventilation of the bucket elevator when transferring pellets from the pellet mill to the cooler. However, air should not be drawn through a long chain starting from the pellet mill through the bucket elevator because volatile organic acids form during pelleting, which can quickly corrode the bucket elevator casing and other unprotected parts. An alternative is to design the bucket elevator in stainless steel.

The main drawback of a bucket elevator is the limited access to the belt inside the shafts, as well as the difficulty in cleaning and inspecting inside the tension and drive sections. When transporting hot pellets, dust settles with condensate into a dense layer and may later detach in pieces, jamming the belt and leading to bucket tears and breaks at the attachment points. This issue is fairly successfully compensated by active ventilation of the bucket elevator when transferring pellets from the pellet mill to the cooler. However, air should not be drawn through a long chain starting from the pellet mill through the bucket elevator because volatile organic acids form during pelleting, which can quickly corrode the bucket elevator casing and other unprotected parts. An alternative is to design the bucket elevator in stainless steel.

For the reasons described above, using a bucket elevator to move raw sawdust and wood chips, especially at sub-zero temperatures, is completely unjustified due to frequent stoppages and difficult cleanings. Raw biomass easily freezes to the inclined chute, which is crucial for loading the buckets. Purely hypothetically, a hybrid of a bucket elevator and a chain conveyor is possible, where large steel buckets are moved on two vertical chains, and material is fed onto them from a horizontal belt conveyor. In the area of biomass processing, this is hardly applicable, as one of the first pieces of equipment is a dryer with a heat generator, making it impractical to place them on an upper floor due to their size and weight.