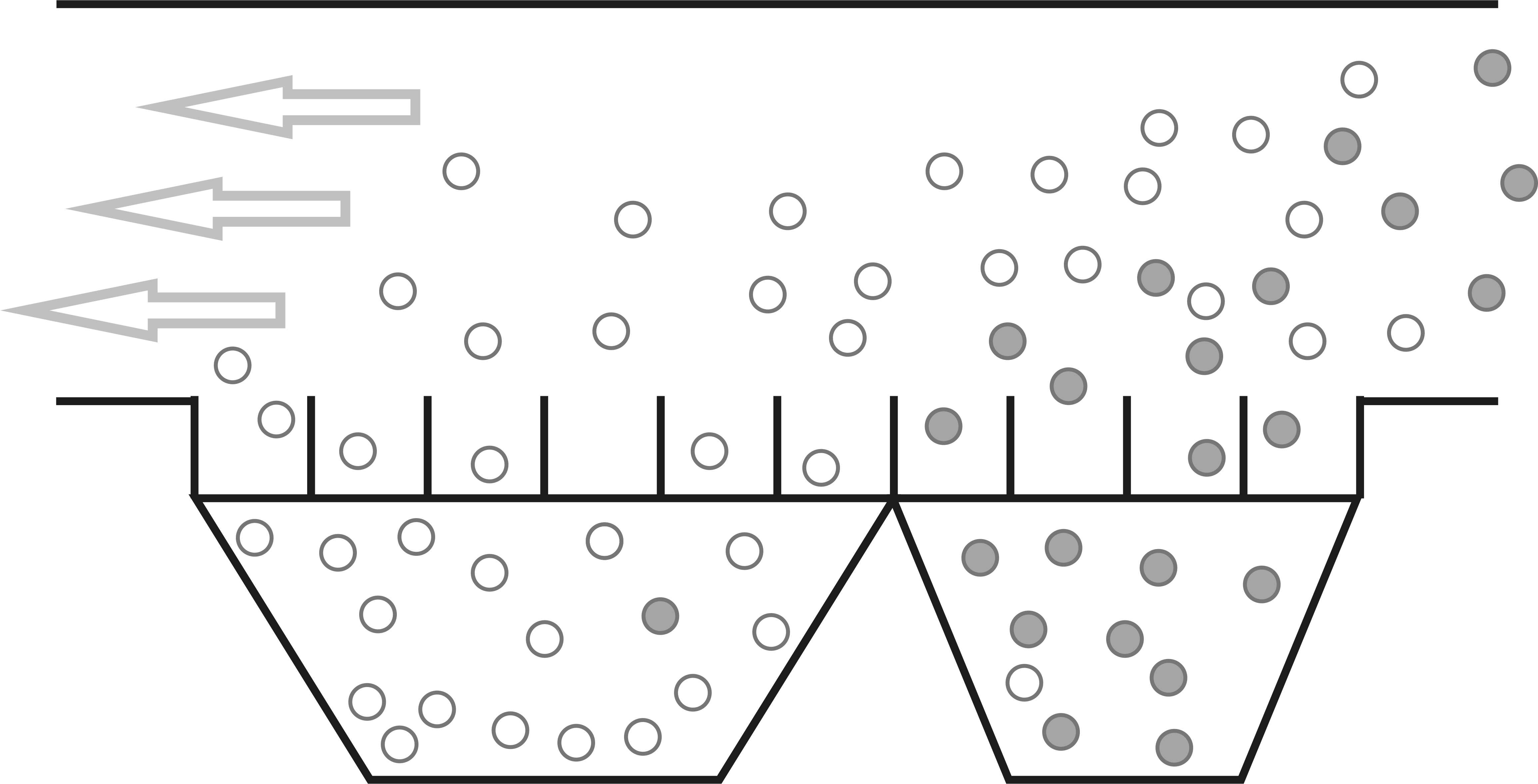

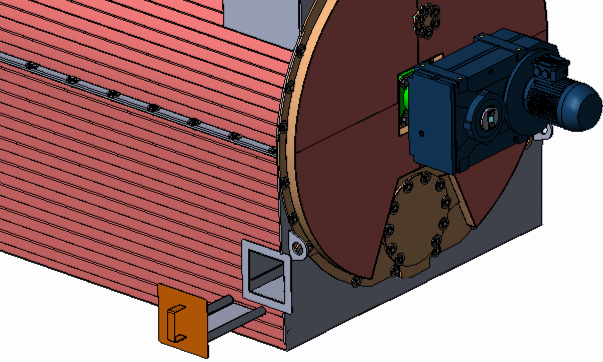

The principle of the bucket-rotary dryer is similar to that of a traditional drum dryer. In a large barrel-shaped container, there is active mixing of the material with blown thermal agent, transferring heat both through attachments and directly from gases to the material. Due to its long cylindrical body, it is also called a rotary drum or bucket drum dryer. Important characteristics like the large volume and shape, which can lead to a powerful explosion if pyrolysis gases accumulate, are what make it similar to ordinary drum dryers. Other than that, the device retains the advantages of a drum dryer while eliminating most of the drawbacks.

The rotor carries buckets that scoop up sawdust from the hollow body and shower the material onto adjacent attachments, acting like the curved blades of a drum dryer. The buckets, like the drum blades, are evenly distributed in volume, and rings on the rotor create flows and vortices in the radial direction. The entire rotor assembly is a spatially rigid structure resembling a multidimensional truss. Thus, with the relatively small mass of the rotor and the small diameter of the centrally located shaft, rotor deflection is only 2-3 mm (0.08-0.12 inches) over a span between the supporting bearings of 6-7 meters (20-23 feet). The gap between the bucket edges and the cylindrical body is usually left as 15-20 mm (0.6-0.8 inches), which prevents contact under load or when larger particles enter and also eliminates "dead" zones of material settling. This results in a more efficient use of the dryer’s volume and reduces fire hazards by avoiding spots where material can overheat.

The rotor carries buckets that scoop up sawdust from the hollow body and shower the material onto adjacent attachments, acting like the curved blades of a drum dryer. The buckets, like the drum blades, are evenly distributed in volume, and rings on the rotor create flows and vortices in the radial direction. The entire rotor assembly is a spatially rigid structure resembling a multidimensional truss. Thus, with the relatively small mass of the rotor and the small diameter of the centrally located shaft, rotor deflection is only 2-3 mm (0.08-0.12 inches) over a span between the supporting bearings of 6-7 meters (20-23 feet). The gap between the bucket edges and the cylindrical body is usually left as 15-20 mm (0.6-0.8 inches), which prevents contact under load or when larger particles enter and also eliminates "dead" zones of material settling. This results in a more efficient use of the dryer’s volume and reduces fire hazards by avoiding spots where material can overheat.

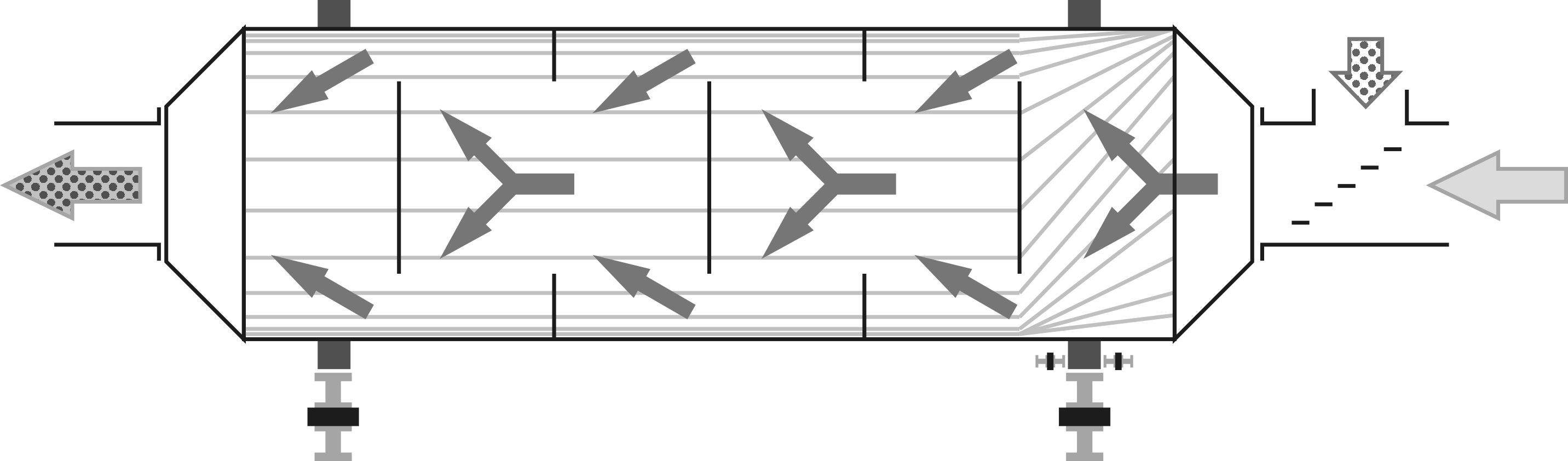

The stationary body provides the following advantages:

- Separate feeding of material and thermal agent prevents particle accumulation in the inlet duct and their ignition. The duct with the thermal agent usually approaches vertically downward and reverse entry of even small fractions is eliminated. Material is fed from the end, and such compact arrangement allows placing the dryer in very tight spaces without compromising functionality or creating maintenance difficulties.

- The stationary flange connections to the ducts prevent any kind of maintenance issues with seals. Vibrations from operation and shifts that could damage ducts are excluded.

- The rotor with buckets, the only moving part of the dryer, is supported by just two bearings installed outside the body. The bearings are selected with a large load capacity, work in low temperatures, with good lubrication, and at extremely low RPMs. They can last the entire life of the device. Compared to the hassles with bands and drum support stations, the operating cost is almost zero.

- The dryer drive is either directly attached to the rotor shaft through a key or uses a chain drive with relatively small sprocket diameters and long life. If the frequency converter is set to limit the maximum torque, breakdowns and drive-related repairs are completely eliminated. A multi-stage protection system can first warn about approaching the load limit and, upon reaching it, will give a clear signal for an emergency shutdown with an automatic stop of all components without ignition.

- The absence of a large moving drum drastically increases operational safety.

Notably, the power of the bucket-rotary dryer’s drive does not usually differ from that installed in a classic drum dryer for similar-sized units. The adequate gap between the bucket and the body ensures easy sliding of material along the polished walls, and tumbling from the bucket to other attachments is not different from the mechanics of material movement inside a traditional single-pass drying drum.

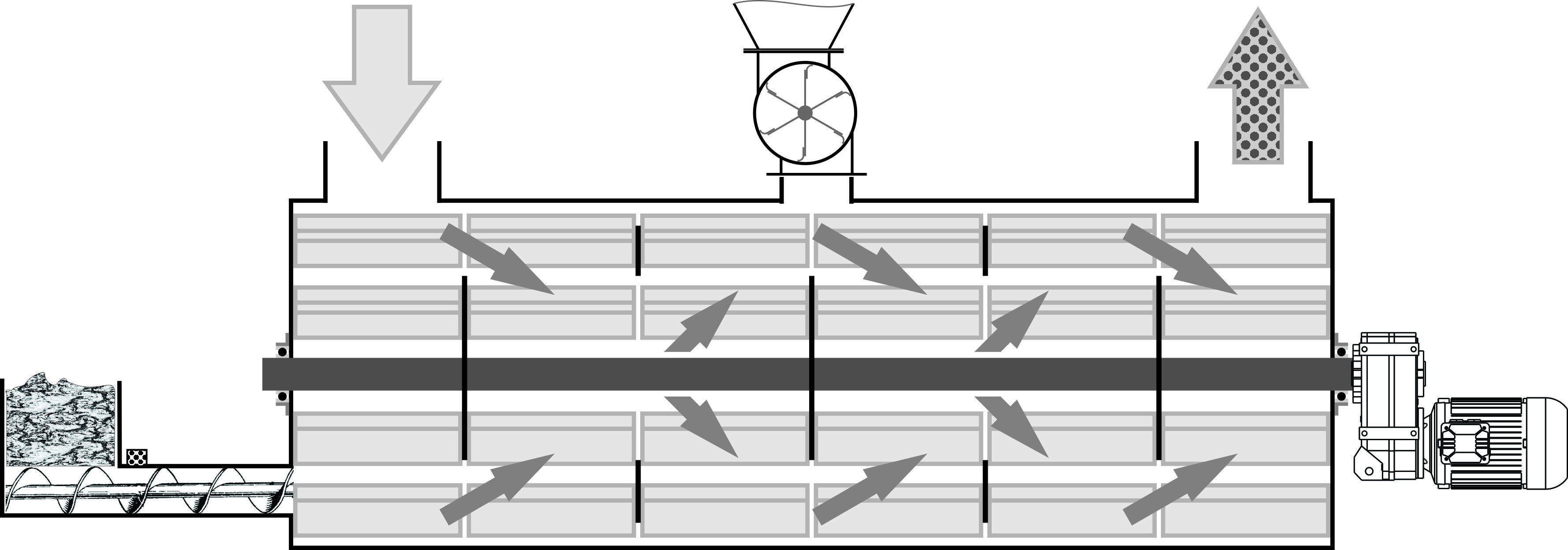

The advantage of using the dryer is that the raw material can be loaded from above through separate hatches located along the dryer. This solution is used for simultaneous drying of raw materials with different initial moisture content or for gentle handling of additives that are not resistant to high temperatures. When drying wood waste, shavings obtained from four-sided planers, typically with a moisture content of 14-16%, are fed into the middle of the dryer. Adding it in its original state to dry sawdust reduces the quality of the pellets because the shavings break into fibers that create cracks due to excess moisture. Adding the shavings to the raw material at the dryer inlet significantly increases the risk of ignition since the fine and dry material ends up in a gas stream with a temperature exceeding the ignition threshold of wood. In the production of complex organic fertilizers, sapropel is mixed with peat at the beginning of the drying process, and manure is introduced 2-3 meters (7-10 feet) from the start. This sequence drastically reduces nitrogen losses from the decomposition of amines and the sublimation of carbon ammonium from the wet mass. The upper flanges of the dryer, free from raw material feeding, are covered with explosion vents anchored to the body with a chain.

The advantage of using the dryer is that the raw material can be loaded from above through separate hatches located along the dryer. This solution is used for simultaneous drying of raw materials with different initial moisture content or for gentle handling of additives that are not resistant to high temperatures. When drying wood waste, shavings obtained from four-sided planers, typically with a moisture content of 14-16%, are fed into the middle of the dryer. Adding it in its original state to dry sawdust reduces the quality of the pellets because the shavings break into fibers that create cracks due to excess moisture. Adding the shavings to the raw material at the dryer inlet significantly increases the risk of ignition since the fine and dry material ends up in a gas stream with a temperature exceeding the ignition threshold of wood. In the production of complex organic fertilizers, sapropel is mixed with peat at the beginning of the drying process, and manure is introduced 2-3 meters (7-10 feet) from the start. This sequence drastically reduces nitrogen losses from the decomposition of amines and the sublimation of carbon ammonium from the wet mass. The upper flanges of the dryer, free from raw material feeding, are covered with explosion vents anchored to the body with a chain.

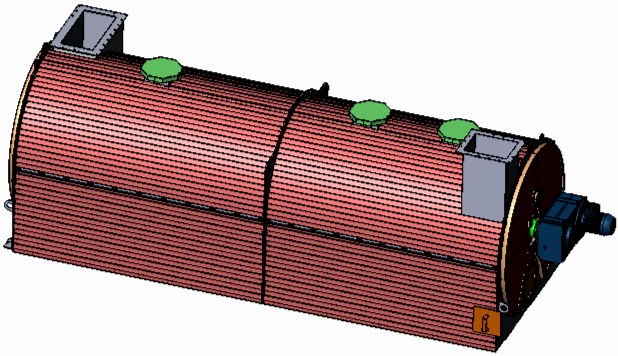

When ordering a bucket-rotary dryer, pay attention to the construction of the body: it should be split. This significantly simplifies the inspection and replacement of buckets in confined production conditions. Also, it is highly desirable to install a platform over the insulating sheath to prevent the profile sheet from denting, as damage to the sheath leads to dust accumulation in the insulation and its ignition. The stationary body naturally invites its use as part of the pathway for personnel movement during equipment maintenance.

Since the material exits with spent gases and steam vertically upwards, installing a standard stone catcher, as with classic drums, is either impossible or would entail unnecessary bends in the air ducts. It is much simpler to provide a sliding tray integrated into the lower part of the body at the end of the cylinder in the direction of bucket movement. Stones and other heavy impurities that are not picked up by gas flows will accumulate in it.

Since the material exits with spent gases and steam vertically upwards, installing a standard stone catcher, as with classic drums, is either impossible or would entail unnecessary bends in the air ducts. It is much simpler to provide a sliding tray integrated into the lower part of the body at the end of the cylinder in the direction of bucket movement. Stones and other heavy impurities that are not picked up by gas flows will accumulate in it.

This type of dryer allows the installation of a discharge screw along the bottom of the body parallel to the rotor axis for unloading material with high bulk density or for operation at high temperatures with low heat agent flows. This is useful for thermal processes such as roasting grains, pre-pyrolysis of rice hulls, or drying mineral raw materials.