Chain conveyors are versatile for transporting any bulk material, although they are the most expensive option. They are even used to carry pellets from under the pellet mill, and in such cases, they are made entirely of stainless steel. Unlike belt conveyors, they can feed material at an angle greater than 45° to the horizontal. With a well-thought-out design, they are easy to maintain, perform well with non-uniform or overly wet wood chips, and transport relatively sticky materials steadily. However, they may stop if large pieces of wood get caught under the sprocket. They differ by the number of chains—single-chain or double-chain, by the feeding method—with the lower or upper branch, straight or with a bend, and they also vary by the types of scrapers and chains installed.

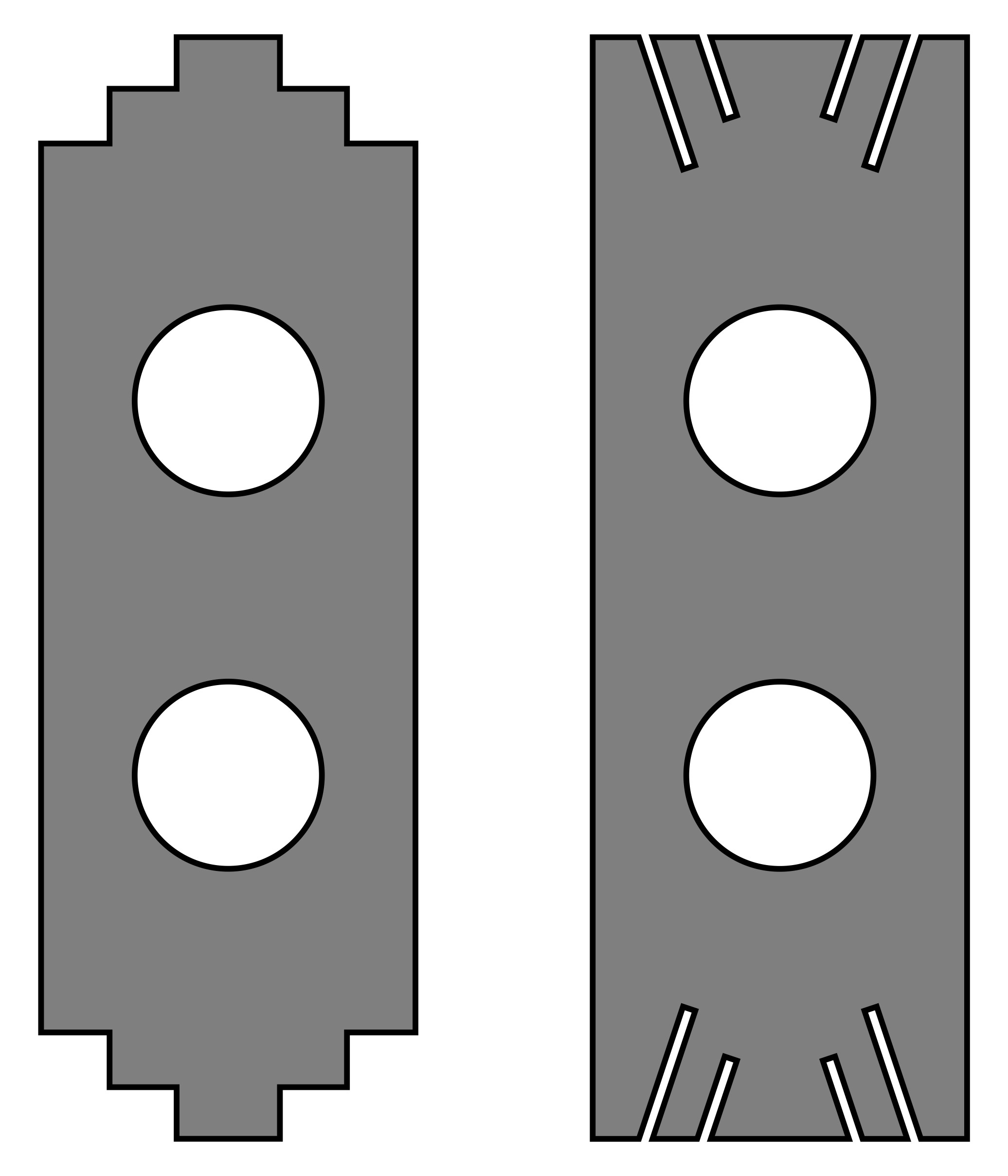

Single-chain conveyors are cheaper as they utilize a chain that is twice as short and only two sprockets instead of four. However, the center-mounted scraper reduces resistance to skewing and jamming, especially when transporting relatively large wood chips. Therefore, for single-chain conveyors with anchor or conveyor chains, it is recommended to use scrapers no wider than 200 mm (8 inches) and to leave gaps of at least 20 mm (0.8 inches) to the walls on each side. When using long-link drag chains, scrapers can be made up to 400 mm (16 inches) wide, but this type of chain is not as common, so it is not advisable to design special sprockets for it. Double-chain conveyors range from 350 to 1000 mm (14 to 39 inches) in width. The minimum width is determined by economic feasibility, while the maximum width is governed by the required throughput and the interdependent height of the conveyor and chain strength.

Single-chain conveyors are cheaper as they utilize a chain that is twice as short and only two sprockets instead of four. However, the center-mounted scraper reduces resistance to skewing and jamming, especially when transporting relatively large wood chips. Therefore, for single-chain conveyors with anchor or conveyor chains, it is recommended to use scrapers no wider than 200 mm (8 inches) and to leave gaps of at least 20 mm (0.8 inches) to the walls on each side. When using long-link drag chains, scrapers can be made up to 400 mm (16 inches) wide, but this type of chain is not as common, so it is not advisable to design special sprockets for it. Double-chain conveyors range from 350 to 1000 mm (14 to 39 inches) in width. The minimum width is determined by economic feasibility, while the maximum width is governed by the required throughput and the interdependent height of the conveyor and chain strength.

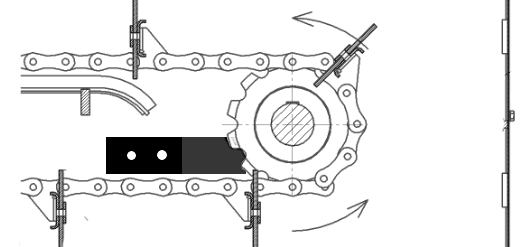

On double-chain conveyors, it is much easier to install sprocket protection from material. Few manufacturers notice that a simple installation of a curved plate close to the sprocket and chain can dislodge chips or grass debris from the links, preventing material from packing between the sprocket teeth. Such cleaners appear 1-2 weeks after a plant starts up if workers realize the causes of sudden chain derailments. They are usually made from steel strips 30 mm (1.2 inches) wide and at least 3 mm (0.12 inches) thick, with a bend angle of about 30°. This cleaner is attached to the conveyor body with two bolts with M12 or M16 threads, or sometimes it is simply welded for quicker installation, as its wear is minimal and usually doesn't require regular replacement.

On double-chain conveyors, it is much easier to install sprocket protection from material. Few manufacturers notice that a simple installation of a curved plate close to the sprocket and chain can dislodge chips or grass debris from the links, preventing material from packing between the sprocket teeth. Such cleaners appear 1-2 weeks after a plant starts up if workers realize the causes of sudden chain derailments. They are usually made from steel strips 30 mm (1.2 inches) wide and at least 3 mm (0.12 inches) thick, with a bend angle of about 30°. This cleaner is attached to the conveyor body with two bolts with M12 or M16 threads, or sometimes it is simply welded for quicker installation, as its wear is minimal and usually doesn't require regular replacement.

A plate is installed 5-10 mm (0.2-0.4 inches) from the lower or upper chain depending on the direction of rotation. Interestingly, such devices allow operation even under a pile-up of material, which is quite common with incorrect equipment design or installation. It should be noted that even such a small modification can void the manufacturer's warranty obligations, and this additional part may hinder conveyor maintenance, as it can complicate chain replacements or adjustments via the shaft adjustment mechanism.

A plate is installed 5-10 mm (0.2-0.4 inches) from the lower or upper chain depending on the direction of rotation. Interestingly, such devices allow operation even under a pile-up of material, which is quite common with incorrect equipment design or installation. It should be noted that even such a small modification can void the manufacturer's warranty obligations, and this additional part may hinder conveyor maintenance, as it can complicate chain replacements or adjustments via the shaft adjustment mechanism.

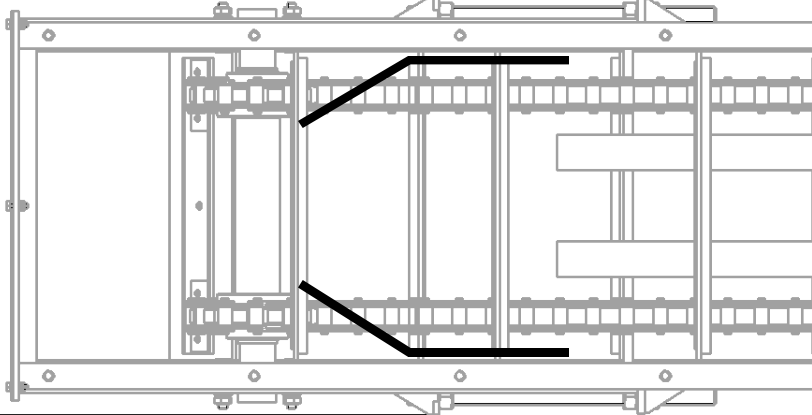

Conveyors with upper and lower feed branches differ by having a dividing wall between the opposing moving scrapers and the chain's direction of movement. For fibrous, wet, and clump-forming materials, the lower feed is preferred. In this configuration, the scrapers return on the upper side, and at the bottom, they scoop up the material and drag it along the lower wall. These scooping motions help keep the lower shaft and sprockets relatively clean, significantly reducing the chance of chain derailment and clogging. Additionally, the lower feed allows for extending the loading and unloading windows by approximately 1-1.5 meters (3-5 feet) further apart with the same overall conveyor length, saving on equipment costs.

Conveyors with upper and lower feed branches differ by having a dividing wall between the opposing moving scrapers and the chain's direction of movement. For fibrous, wet, and clump-forming materials, the lower feed is preferred. In this configuration, the scrapers return on the upper side, and at the bottom, they scoop up the material and drag it along the lower wall. These scooping motions help keep the lower shaft and sprockets relatively clean, significantly reducing the chance of chain derailment and clogging. Additionally, the lower feed allows for extending the loading and unloading windows by approximately 1-1.5 meters (3-5 feet) further apart with the same overall conveyor length, saving on equipment costs.

The speed for the special chain type "TRD" in conveyors is allowed up to 100 meters per minute (330 ft/min). However, for an acceptable replacement interval, it's usually set between 30 and 50 meters per minute (98-164 ft/min). Therefore, productivity increases at the design stage are achieved primarily by increasing width, rather than feed speed. Considering the densest material at a pellet plant is typically chicken manure or grain components, bulk density up to 750 kg/m³ (47 lb/ft³) is considered. Additionally, a friction and external loss coefficient of 1.5-2 is applied.

There is a conveyor based on an anchor chain with side scraper attachments, typically using wooden blocks as scrapers. This design originated in farms and is often used for automatically removing semi-liquid waste from cattle stalls. These conveyors are fairly inexpensive and easy to repair, but they perform relatively well only with semi-liquid material or grain in occasional use. On biomass like sawdust, wood chips, or wet shavings, operation is extremely unstable because the anchor chain lacks rigidity against twisting, and scrapers rotate easily when passing over accumulated bulk material. Sprockets for the anchor chain are also prone to icing and filling with wood mass. Using such a chain in dual-chain conveyors is impossible, as it quickly and unevenly stretches, causing scraper misalignment and leading to frequent breakages of both scrapers and chains.

There is a conveyor based on an anchor chain with side scraper attachments, typically using wooden blocks as scrapers. This design originated in farms and is often used for automatically removing semi-liquid waste from cattle stalls. These conveyors are fairly inexpensive and easy to repair, but they perform relatively well only with semi-liquid material or grain in occasional use. On biomass like sawdust, wood chips, or wet shavings, operation is extremely unstable because the anchor chain lacks rigidity against twisting, and scrapers rotate easily when passing over accumulated bulk material. Sprockets for the anchor chain are also prone to icing and filling with wood mass. Using such a chain in dual-chain conveyors is impossible, as it quickly and unevenly stretches, causing scraper misalignment and leading to frequent breakages of both scrapers and chains.

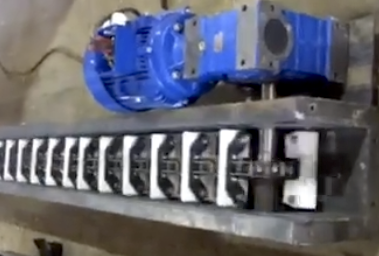

The photo shows an example of a TRD-38 chain conveyor that has become unevenly stretched after being jammed by a log. Without replacing the chain, this cannot be properly adjusted due to the alternating tension and loosening of the chains during operation. This is not the only flaw of the conveyor in the photo. The use of pieces of conveyor belt instead of scrapers is quite noticeable. Under load, the rubber bends and pulls the chains toward the center, causing them to slip off the sprockets. Additionally, when rubber enters the hammer mill, it usually results in significant damage because the hammers rebound from elastic impacts, hitting the rotor shaft or each other, often leading to their breakage. More viscous and less elastic materials can settle in the grinding chamber, and if stopped in time, it may avert fatal damage. It is much safer to use polymer scrapers, which have a low friction coefficient against the steel body and maintain their shape under load, but easily break and get ground up in the hammer mill. To strengthen against bending, a steel angle is also used as the base of the scraper, onto which plastic is bolted or riveted. Every threaded connection within the conveyor should be securely fixed either with special pastes or by riveting the threads almost to the nut. Given the number of connections, relying on regular tightening during scheduled maintenance would be quite uncertain.

The photo shows an example of a TRD-38 chain conveyor that has become unevenly stretched after being jammed by a log. Without replacing the chain, this cannot be properly adjusted due to the alternating tension and loosening of the chains during operation. This is not the only flaw of the conveyor in the photo. The use of pieces of conveyor belt instead of scrapers is quite noticeable. Under load, the rubber bends and pulls the chains toward the center, causing them to slip off the sprockets. Additionally, when rubber enters the hammer mill, it usually results in significant damage because the hammers rebound from elastic impacts, hitting the rotor shaft or each other, often leading to their breakage. More viscous and less elastic materials can settle in the grinding chamber, and if stopped in time, it may avert fatal damage. It is much safer to use polymer scrapers, which have a low friction coefficient against the steel body and maintain their shape under load, but easily break and get ground up in the hammer mill. To strengthen against bending, a steel angle is also used as the base of the scraper, onto which plastic is bolted or riveted. Every threaded connection within the conveyor should be securely fixed either with special pastes or by riveting the threads almost to the nut. Given the number of connections, relying on regular tightening during scheduled maintenance would be quite uncertain.