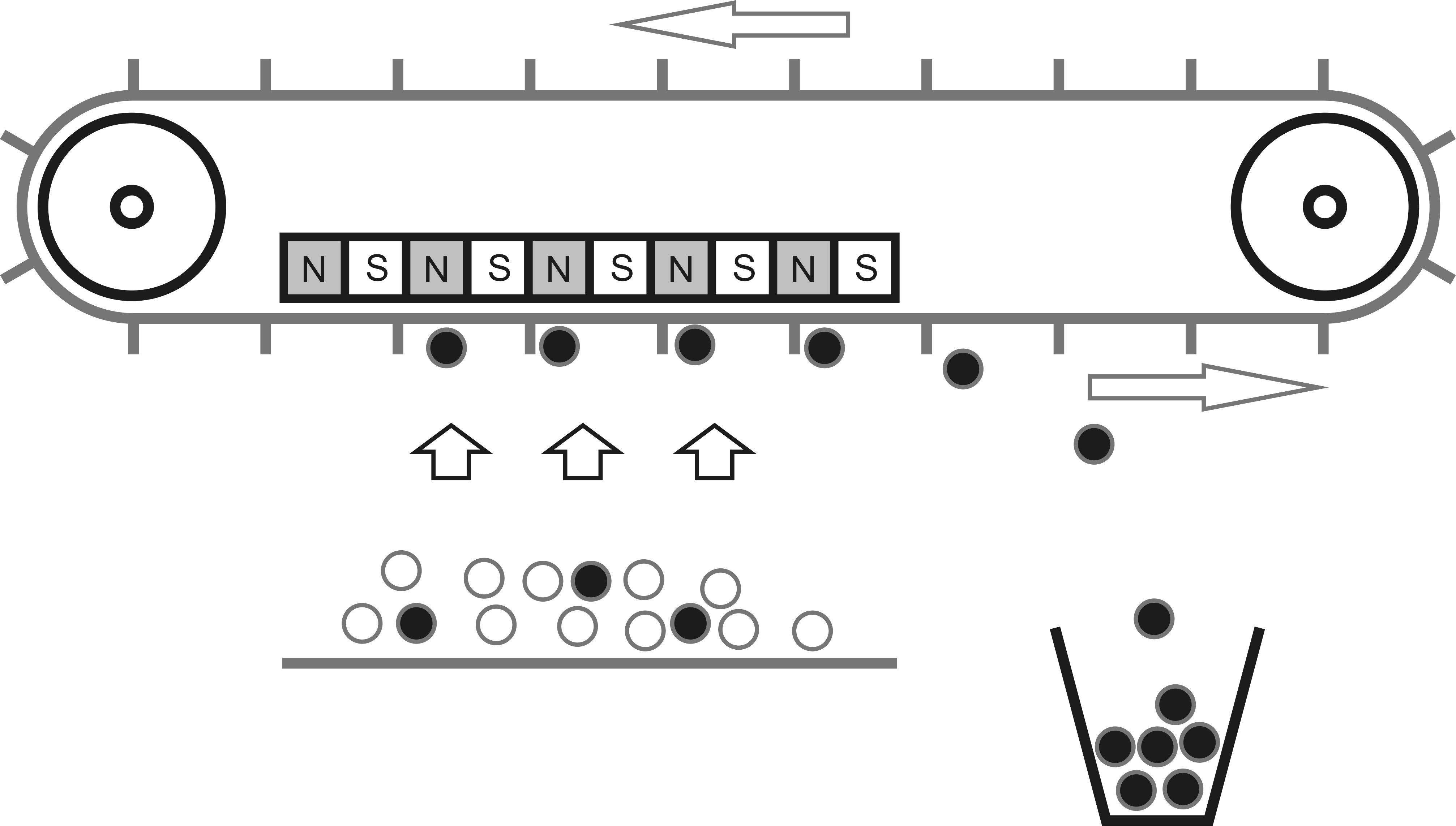

After visually inspecting all conveyors, checking their drive connections, chain tension, lubrication, and verifying fans and rotary valves, you should turn everything on simultaneously. This includes the dryer and heat generator, but all types of grinders and the pellet mill should remain powered off. Make sure to open the appropriate hatches and doors for the free unloading of any material that might fall out of the pelletizing line. During manufacturing and installation, lost nuts, electrode pieces, and other metallic debris often remain in equipment cavities, which can be difficult to spot. Running all transport systems on idle for 15-20 minutes is likely to expel and gather all this debris before it reaches the knives, hammers, and die.

Running on idle does not guarantee that no parts remain stuck in corners. The initial batches of raw material should be emptied before reaching the critical machinery and simply taken to the landfill. Complete confidence regarding foreign objects usually comes after 2-3 working shifts, when magnetic separators stop collecting debris and all friction surfaces are smoothed with sawdust, changing the pellet color from gray to light cream.

During such idle runs, there is typically enough time to check the smoothness of chain movement, belt tracking from drums, unusual noises, and shaft misalignments. Before starting, it is useful to list all drives in a separate table, noting the nominal current from each drive's nameplate and its connection number in the control panel. While running on idle, measure the actual current values on each phase. Even when there is no phase imbalance, a significant current difference on a specific motor can indicate a manufacturing defect such as a short-circuited winding. For chain and belt conveyors, rotary valves, and fans, these data help avoid emergency stoppages during operation. It’s common for a fan to operate at maximal currents due to improper pneumatic system adjustments, even without raw material, so airflow should be preemptively reduced. Belts might be overly tightened in conveyors, and material feed will trigger protection when the plant is running. Using excessively hard seals in rotary valves can cause increased load, and exercising them for longer periods to seat them with the housing before plant startup is beneficial.