All types of chippers and hammer mills share one common feature – the main tool is a fast-rotating rotor, which carries potential danger. If you convert the rotor mass and speed of the hammer mill into explosive equivalent energy, you might end up with 10-15 kilograms (22-33 lbs) of TNT. Roughly speaking, the destructive power can be comparable if the bearings seize and the rotor exits the housing. Each hammer of a mill or knife of a chipper usually carries 1-2 orders of magnitude more kinetic energy than a bullet from large-caliber firearms. Therefore, meticulous attention to assembly and adjustment of such equipment is necessary. Operating them with open doors or without safety guards is strictly prohibited!

At one site, it happened that the hammers were made from a different steel grade, which became very brittle after hardening. Upon startup, one hammer broke loose, triggering a chain reaction that shattered the others. As a result, parts of the hammers flew out through the feed chute, puncturing the roof with 100-150mm (4-6 inches) holes. If this had occurred with an open cover and without screens, the entire production site came under fire.

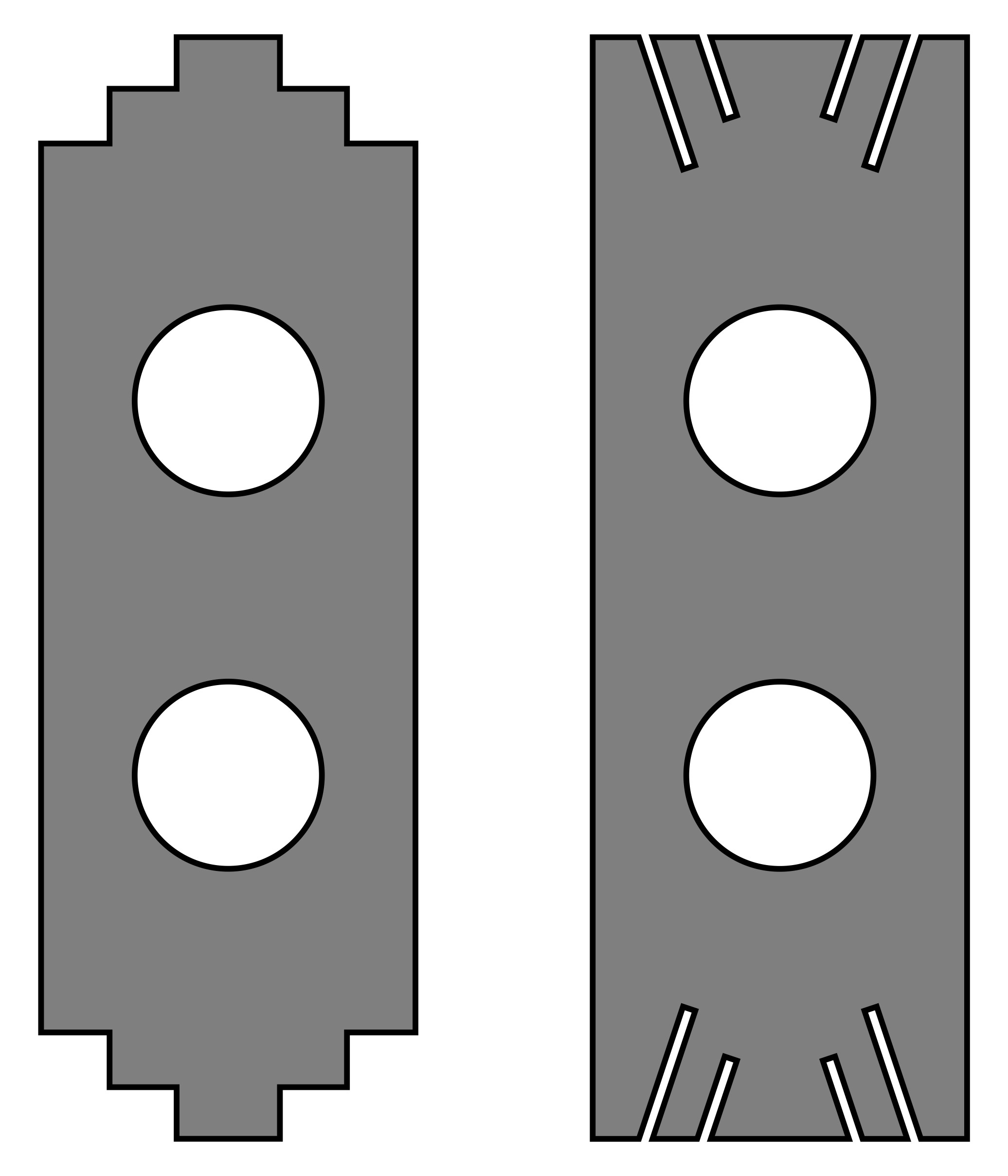

In a chipper, knives are typically secured using hardened bolts tightened with a torque wrench. Since knife replacement and sharpening are relatively routine maintenance tasks, it's advisable to double-check the bolt tightness. On the rotor of a hammer mill, studs and nuts with deformable washers are often used for fixation. It's important to learn the procedure for changing hammers and verify each fastener. Since any significantly massive rotor cannot be manufactured perfectly, it must undergo balancing. You can confirm that this has been done by checking for welded or riveted balancing weights. Photos of the found weights can help verify their presence later when the rotor shows significant wear or if vibration occurs.

Due to the large mass and high peripheral speeds, specialized grease is often used for the bearings of such equipment. It's important to have various grease guns on hand, pre-marked with different colors or labels to prevent mixing. Because of high speeds, bearing assemblies are filled with grease up to one-third or less of the volume. Therefore, it's crucial to review the operating manual and open the bearing housing to check for lubrication. Relying on factory readiness alone exposes you and your colleagues to unjustified risk. If the bearings are overfilled to the point of grease extrusion from seals, the mill should be run several times, avoiding overheating the bearings and removing excess grease with a rag after each stop.

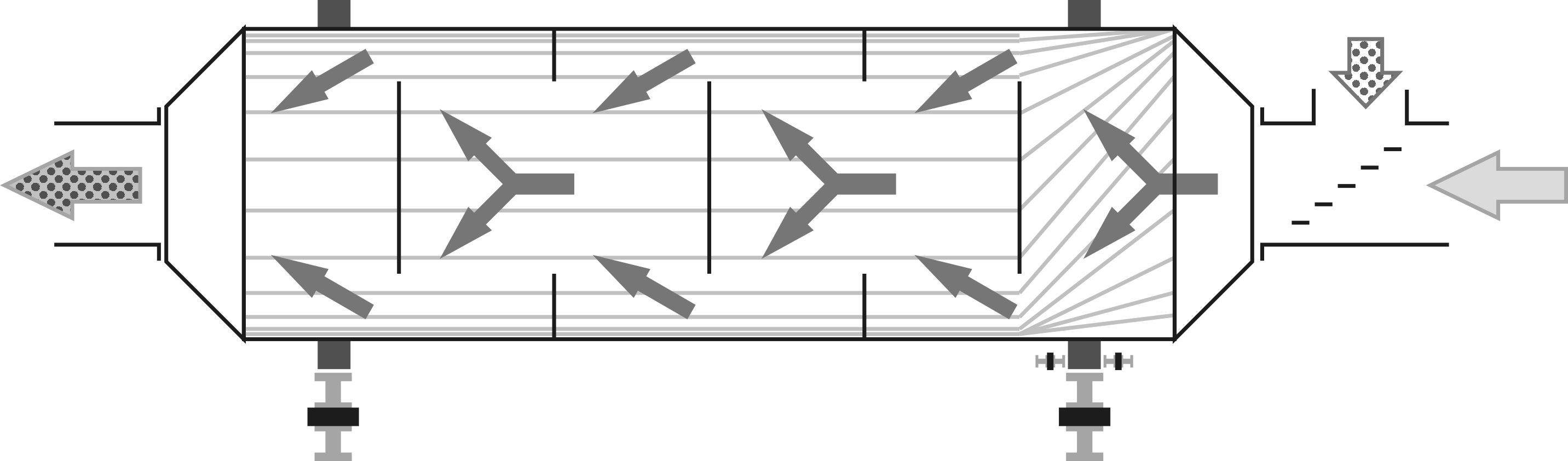

Following the startup of any grinder, it's essential to check for vibration, ensure the bearing temperatures remain within permissible limits, and verify the feed control and emergency sensors are functioning properly. If excessive vibration is detected, especially if it's noticeable on concrete floors, recheck the transport restraints' removal from vibration mounts and confirm the machine's mounting alignment. High vibration can also result from improperly assembled rotors with uneven hammer or knife weights. Typically, hammers are marked by weight and equal-weight sets are hung on opposite sides of one rotor section, although individual hammers may vary significantly in weight.

If the grinder or hammer mill is functioning properly, it is advisable to test their load capacity separately before the full startup. Raw material should be fed into them, adjusting the dosage and checking the maximum permissible rates. Then, record the feeder frequency that corresponds to nearly full load and create a maximum threshold for the frequency converter, which will signal impending overload and limit the feed rate. This will help prevent sudden plant shutdowns, especially when the dryer is already in operation and may release an excessive amount of material at any moment.