A chipper is a specialized machine used for "chopping" logs, slabs, and other relatively long types of raw materials with small cross-sections that do not contain nails or other impurities that could dull the blades. Depending on the requirement, chippers can be adjusted to produce wood chips in three length sizes:

- 15-25 mm (0.6-1 inch) – the most suitable size for further processing into pellets, simple drying to obtain chips for smoking, or coloring for colored mulch. Assuming other parameters are met, it can be conditionally called "technological."

- 30-50 mm (1.2-2 inches) – the most popular size for use as fuel in heaters and boilers with a capacity of 1 MW, as at this chip size, maximum productivity of chippers is achieved, and this size of chip is usually easily conveyed by screw feeders.

- 50-100 mm (2-4 inches) – a size for large boiler houses with hydraulic fuel feed and moving grates, usually obtained on large shredders from secondary processing waste.

For pellet production, obtaining a fraction within 25 mm (1 inch) is most cost-effective. This is because wet wood is relatively easy to cut across the fibers, but the fibers are extremely difficult to break under the blows of hammers during further grinding. Increasing the power of the chipper by 1.5 times to reduce the chip size allows for a threefold reduction in electricity consumption when crushing raw chips to a fraction suitable for quality drying.

Chippers are divided according to the design of the working unit into disc and drum chippers. Disc chippers are much cheaper and easier to manufacture because they utilize the rotor's inertia, reducing the load on the bearings, and in small, semi-household models, allow the rotor to be mounted directly on the motor shaft. The ability to feed material at an angle to the rotor plane in these chippers not only reduces impact load but also facilitates the natural pulling in of pieces. This eliminates the need for additional feeding mechanisms but lowers the chip quality and productivity. Another advantage of disc units is the possibility of installing hammers on the rotor for additional chip crushing, successfully used in the production of arbolite raw material in small quantities. A disadvantage of disc chippers, especially without forced feed, is clogging with fibrous raw materials. When feeding very thin and wet slab, the bark fibers wind onto the shaft and clog the gap between the casing and the rotor.

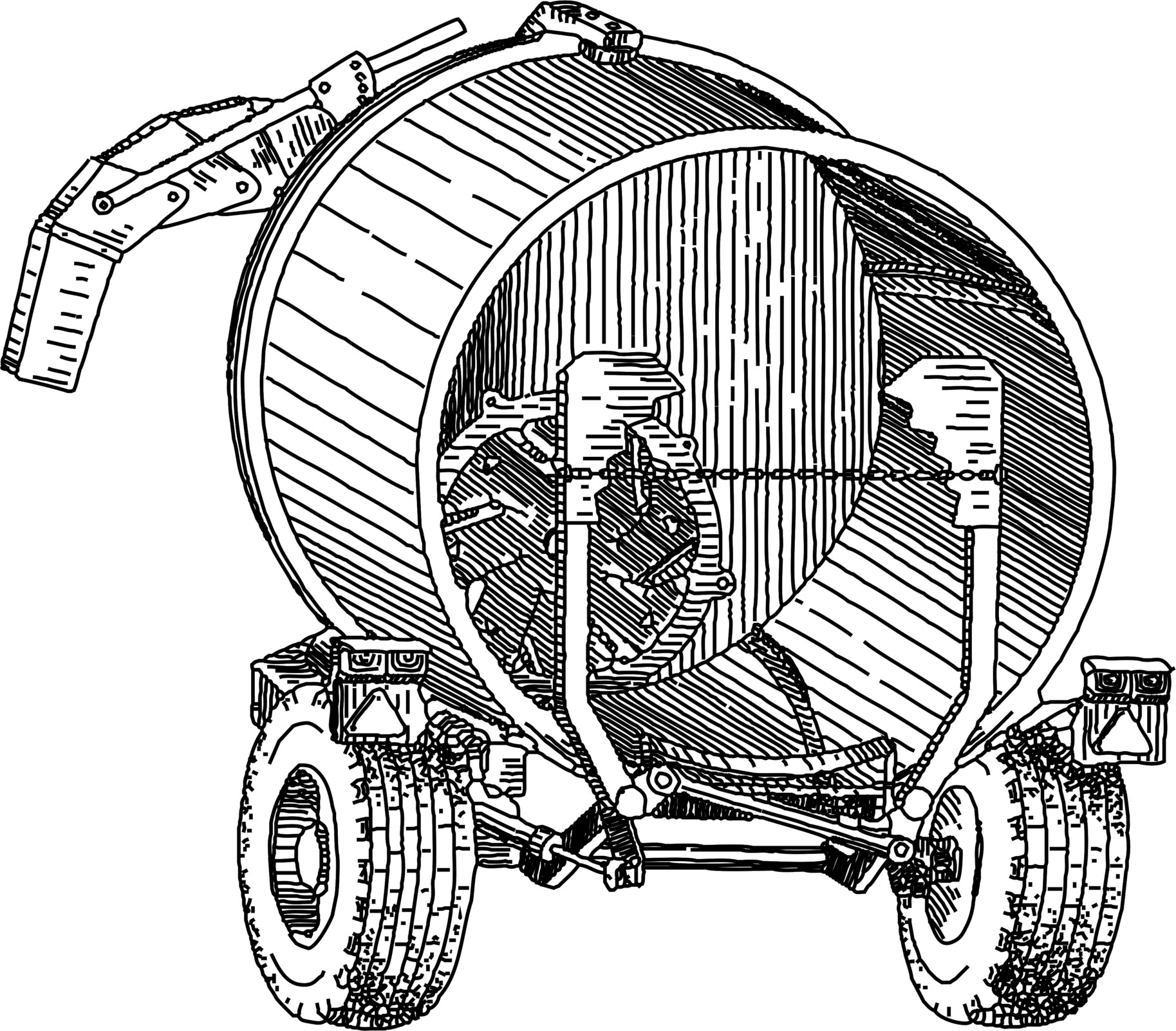

Drum chippers are the classic option for industrial chip production. They feature massive bearing units, a reliable and adjustable material feed mechanism, greater productivity, longer maintenance intervals, and low chip production costs.

Drum chippers are the classic option for industrial chip production. They feature massive bearing units, a reliable and adjustable material feed mechanism, greater productivity, longer maintenance intervals, and low chip production costs.

Both types of machines can be equipped with systems for feeding, load monitoring, automatic lubrication, and other mechanisms that minimize labor time and operating costs. Given the impact loads and the possibility of jamming with a complete stop, belt drives from the main engine are considered the most reliable and safe for chippers. It is highly recommended to install several emergency stop buttons in close proximity to the feeding mechanism and the conveyor to prevent accidents and injuries.

With each rotation of the rotor or drum, the material is typically cut two to four times, depending on the number of knives installed. Sometimes, excessively long knives are divided into several parts and staggered, which not only distributes the load but also minimizes losses in case of a knife breakage. The number of knives installed only indirectly affects the size of the wood chips and is usually calculated based on the required production capacity and specific load.

With each rotation of the rotor or drum, the material is typically cut two to four times, depending on the number of knives installed. Sometimes, excessively long knives are divided into several parts and staggered, which not only distributes the load but also minimizes losses in case of a knife breakage. The number of knives installed only indirectly affects the size of the wood chips and is usually calculated based on the required production capacity and specific load.

The steel used for the knives needs to be extremely hard for wear resistance yet able to withstand impact loads since accidental contact with nails or gravel should not cause deep chipping or cracking. Adding tungsten to alloys provides these properties, so knives made from 6ХВ2С steel need sharpening 2-3 times less frequently than those made from 6ХС and cost only 1.5 times more.

Chip size adjustment on a disc chipper without a feed unit is managed by projecting the knife out of the rotor plane. The anvil or counter-knife only indirectly affects the chip size, ensuring a quality cut without excessive tearing forces. A chip size of 20-30mm (0.8-1.2 inches) is typically achieved with a knife projection of 12-13mm (0.5 inches) from the rotor plane when the feed material is angled 45-60° to this plane. As a rarity, special limiting inserts under the knives of a drum chipper may restrict the cutting layer and significantly reduce chip size. Self-modifying these machines is highly discouraged as it can likely cause severe mechanical damage to equipment and harm to personnel.

Chip size adjustment on chippers with a feed unit is achieved by adjusting the rotation frequency of the conveyor and feed rolls. Often, the control panel includes overload protection, which stops the material feed at 90% of the nominal current load and resumes it when it falls below 50%. Gradually slowing the feed relative to load is strongly discouraged since this will produce chips of vastly varying sizes depending on the initial material size. A screen is often used on drum chippers but does not regulate the bulk of the raw material's chip size. Its purpose is to redirect large chunks for re-chipping. Installing a screen that is too fine will result in frequent blockages and a sharp decrease in productivity.

Special attention should be given to the design and placement of the feed rolls. Typically, a conveyor starts directly beneath them, which carries chips away from the chipper. A gap between the rolls that is too large allows larger wood pieces to enter the finished product. If replacing the ribbed section is impossible, a chute can be installed under the feed unit to remove large pieces.

Special attention should be given to the design and placement of the feed rolls. Typically, a conveyor starts directly beneath them, which carries chips away from the chipper. A gap between the rolls that is too large allows larger wood pieces to enter the finished product. If replacing the ribbed section is impossible, a chute can be installed under the feed unit to remove large pieces.

Slowing the feed by 2-3 times proportionally reduces productivity, so when selecting equipment, divide the stated and verified values by three. For example, a drum chipper with two knives, a 55 kW motor, and a knife width of 600mm (24 inches), is advertised to produce 20 bulk cubic meters per hour of 50mm (2 inches) chips. Therefore, you can achieve only 7-10 cubic meters (247-353 cubic feet) of fine chips, from which 1-1.5 tonnes (2200-3300 pounds) of pellets can be produced with initial raw material moisture content of 55%.

The simplest way to save on purchase is to order a machine of the same size but with three or four knives, proportionally increasing the drive power. This allows maintaining productivity while switching to a finer chip size, keeping the load on the working parts within calculated limits.

It is advisable to purchase a sharpening device with a coolant system and several sets of knives right from the start, so you always have replacements ready for installation. The knife mounting bolts should have a strength of at least 10.9, and they need to be correctly replaced each time the knives are removed, then tightened strictly using a torque wrench. The collision of a knife with a counter-knife often results in the drum being ejected from the housing, the top part of the feeding device being torn off, and other extremely dangerous accidents for employees.

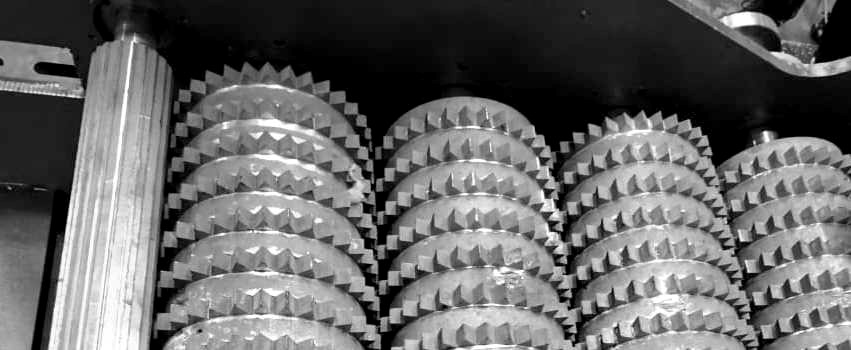

The most economical and convenient chipping machine to purchase and operate is one where claw-like knives are installed instead of long blades. Typically, with a drum width of 600 mm (24 inches), 5 to 11 knives can be accommodated, and this has little effect on the chip fraction. Reducing the number of knives decreases time losses for sharpening and maintenance. To maintain the total cutting edge length for the same machine type and power, the number of installation slots is usually doubled. Thus, a three-knife drum is replaced by a drum with six claw installation slots. The rows are installed with an offset equal to the width of a knife, allowing for a spiral cut. As a result, the narrow cutting part not only cuts the fibers but also creates significant side impacts and breaks off small pieces. This produces sufficiently small material to be fed into the dryer, bypassing a whole range of equipment for further grinding of wet chips. The maximum effect from such a chipping machine is achieved when processing wet round wood and slab wood into biofuel.

A chipping machine with hopper feed is a promising option considering rising fuel prices and stricter environmental regulations for the use of forest resources. It is ideal for chipping stumps, pieces of non-standard logs, and other forest clearing waste. A hopper is installed above the knife-equipped drum, similar to straw bale choppers. The chip fraction is not strongly regulated by the drum's protrusion above the support surface, and restrictive inserts can be applied to regulate the cutting layer.

A chipping machine with hopper feed is a promising option considering rising fuel prices and stricter environmental regulations for the use of forest resources. It is ideal for chipping stumps, pieces of non-standard logs, and other forest clearing waste. A hopper is installed above the knife-equipped drum, similar to straw bale choppers. The chip fraction is not strongly regulated by the drum's protrusion above the support surface, and restrictive inserts can be applied to regulate the cutting layer.

The hopper with paddles is relatively low in height, with a wide funnel above it to facilitate processing crooked stumps together with roots. This unit can be called a universal shredder for shredding raw wood and other large biomass chunks to produce large fuel chips. If the primary product is sieved to remove most of the sand and soil, and additional cleaning is installed on the production line, fuel pellets of at least industrial quality can indeed be produced.

The hopper with paddles is relatively low in height, with a wide funnel above it to facilitate processing crooked stumps together with roots. This unit can be called a universal shredder for shredding raw wood and other large biomass chunks to produce large fuel chips. If the primary product is sieved to remove most of the sand and soil, and additional cleaning is installed on the production line, fuel pellets of at least industrial quality can indeed be produced.

Screw chippers, semi-automatic log splitters, and similar units are hardly applicable for mass wood processing and are not cost-effective for use in biofuel plants. They are either complex and expensive to maintain or have low productivity, or provide poor quality raw material. For instance, a shredder where the drum consists of several dozen circular saws is available. These saws can indeed be sharpened automatically and are available for purchase. However, when recalculating the purchase costs and labor hours per ton of raw material, they are significantly less efficient than traditional methods, although they do provide an immediately fine fraction. The screw chipper provides an almost ideal chip fraction with minimal sawdust impurities, but sharpening and maintenance require unjustifiably high skills in rural areas and consumables show relatively high costs.