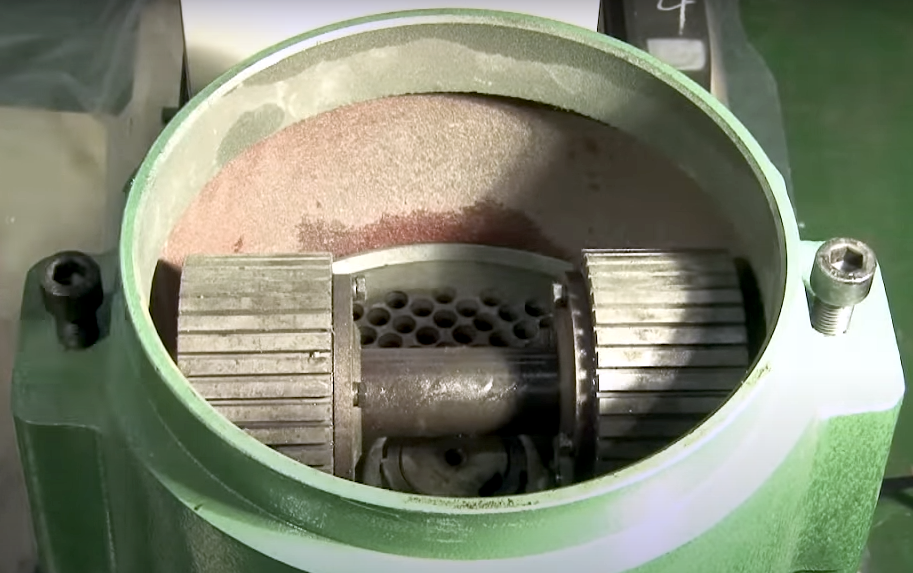

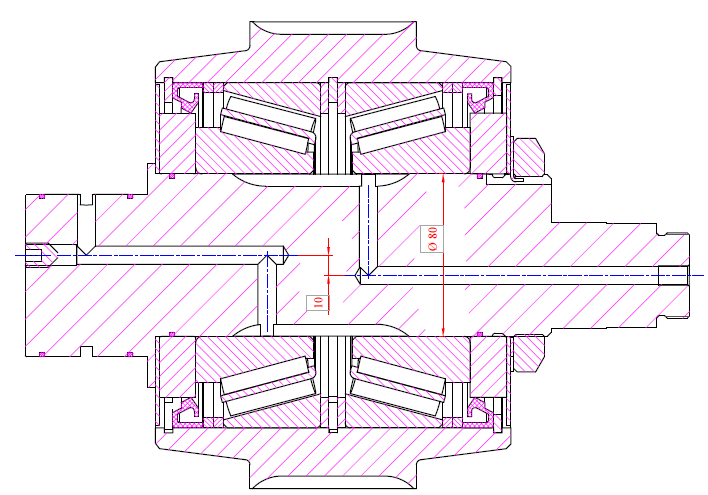

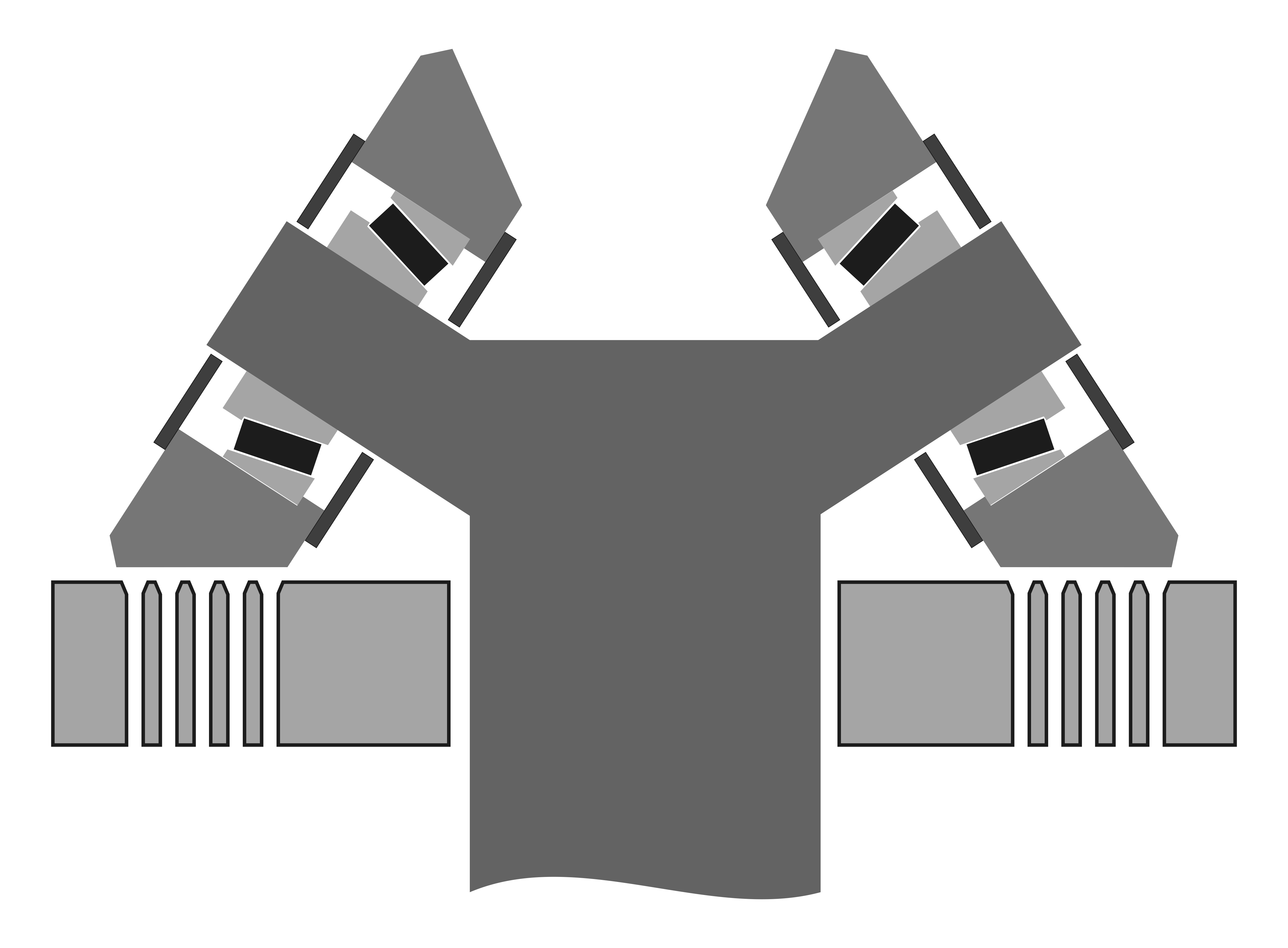

In flat die designs, due to the circular movement of the rollers, their edges move at different linear speeds relative to the die. Considering the load distribution, it is most likely that the inner edge will slip on the die. This leads not only to different wear of the die rows but also to excessive heat loss from friction. In some cases, it makes it impossible to achieve consistently high-quality pellets from both outer and inner rows. On larger models with a capacity of 3-5 tons per hour, this effect is minimal, but on smaller ones, it is a disadvantage. To equalize or at least closely match the linear speeds of the shell edges, they are designed in a conical shape. The roller axes are also positioned at an angle to the die.

In flat die designs, due to the circular movement of the rollers, their edges move at different linear speeds relative to the die. Considering the load distribution, it is most likely that the inner edge will slip on the die. This leads not only to different wear of the die rows but also to excessive heat loss from friction. In some cases, it makes it impossible to achieve consistently high-quality pellets from both outer and inner rows. On larger models with a capacity of 3-5 tons per hour, this effect is minimal, but on smaller ones, it is a disadvantage. To equalize or at least closely match the linear speeds of the shell edges, they are designed in a conical shape. The roller axes are also positioned at an angle to the die.

The construction looks even more exotic when the angle of inclination of the shell to the die is made slightly larger than the cone angle of the bearing inside the roller. This allows the installation of only one tapered roller bearing in the roller. The rolling elements are naturally clamped by the load, and the bearing does not require adjustment throughout its service life. Additionally, a single large-diameter bearing can carry a much larger load than two small ones in the same limited space. The exact angle for the roller axis inclination to the die is determined experimentally and also depends on the track width, the amount of material in the wedge, and the track diameter. Using rare bearings with a small cone angle is not recommended, as the popularity and performance of the equipment depend on the availability of consumables.