Based on the collected information, it is now possible to calculate the expenses for purchasing and installing equipment, as well as labor costs and electricity consumption. What remains to be considered are consumables, building or renting a facility, raw material costs, and packaging.

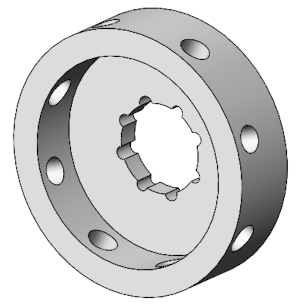

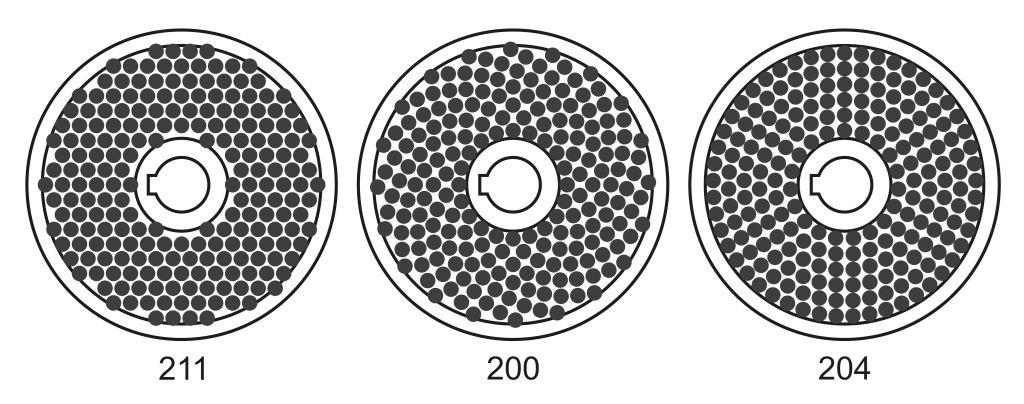

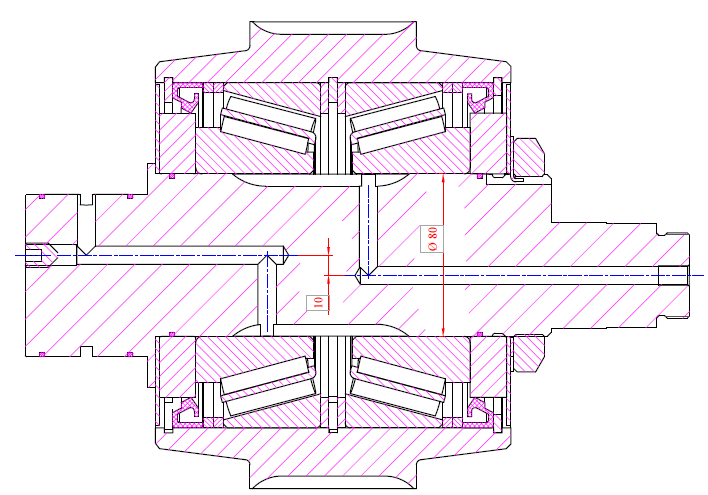

Sellers frequently underestimate figures for consumables by indicating the maximum life span of the die with wear rings and often remain silent about other expenses. However, along with the wear rings, roller bearings often need replacement as well. The consumption of grease is usually not less than 150 grams per ton of pellets. Although rare, eccentric shafts and roller spacers, shear pins with hardened sleeves, and the die diffuser may need regular replacement due to the gradual deformation of the door. Hammers and screens in hammer mills, conveyor belts and chains, and other moving parts contribute noticeably less to the overall cost, but they amount to a comparable sum when combined. For an approximate calculation of consumable costs per ton of pellets, take the price of the die, divide it by its guaranteed life span, and multiply by four. In 80% of cases, this would be the maximum figure where equipment operation is considered normal. If consumption is higher, one should look for reasons of premature wear and weak links in the equipment chain.

The packaging needs can vary greatly depending on the product's purpose, storage conditions, and customer requirements. Packaging should generally be considered a separate business, as distributors often buy pellets in bulk and earn much more from packaging, delivery, and retail sales than the pellet manufacturer itself.

Regarding facility rental and raw material costs, this is a strategic issue. An interested party for a small pellet line often replies that they have their facility and raw material, so it is all free and thus not considered in calculation. However, the facility could be rented to another business, and the sawdust or shavings sold. When all data are consolidated into a single electronic spreadsheet, it often turns out that, considering taxes and all previously overlooked costs, the final profit from pellet production is less than the revenue from renting and selling raw materials. This results in a "sad Excel table."

On one hand, the equipment seller might not want to show such a summary table to a buyer, as it could directly lead to losing the contract. On the other hand, this tool is quite useful for the client. If someone is enthusiastic about the pellet industry, by considering all risks and mitigating unnecessary expenses, they may find the right facility on the third or fifth attempt to reduce raw material transport costs, choose an acceptable type of raw material in terms of fraction, moisture, and quantity, and, as a result, build their dream. Providing a well-developed form for entering all parameters directly on the engineering company's website is a minor expense for a webmaster. However, this online calculator will repeatedly attract clients until they decide to engage in a deal. Thus, any manufacturer's dream is achieved – repeat orders for expanding production or launching new operations, when a waste processor who caught a lucky break has already confirmed the reliability of the partnership and competitors have no opportunity to switch him to their equipment.