Drying material distributed in an even layer on a perforated belt is the most gentle method, allowing for fine adjustment of temperature settings. Minimal mechanical impact virtually eliminates dust emission, and when drying seeds, it does not affect their germination.

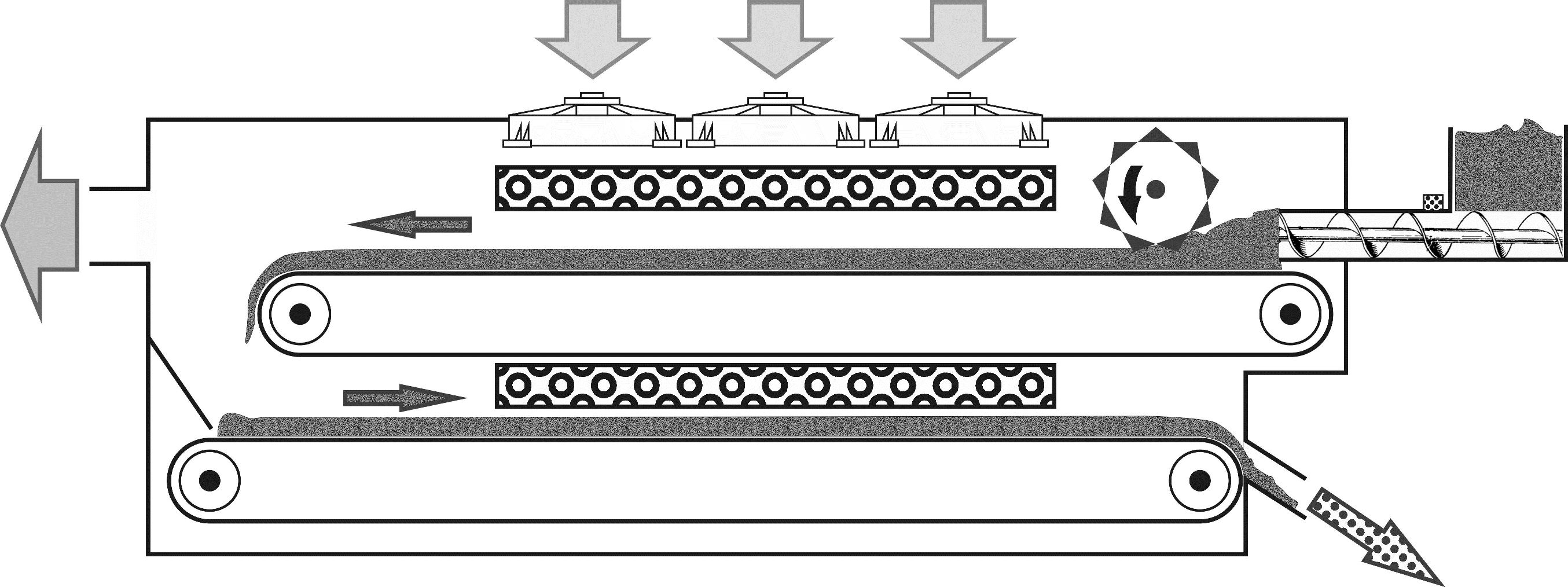

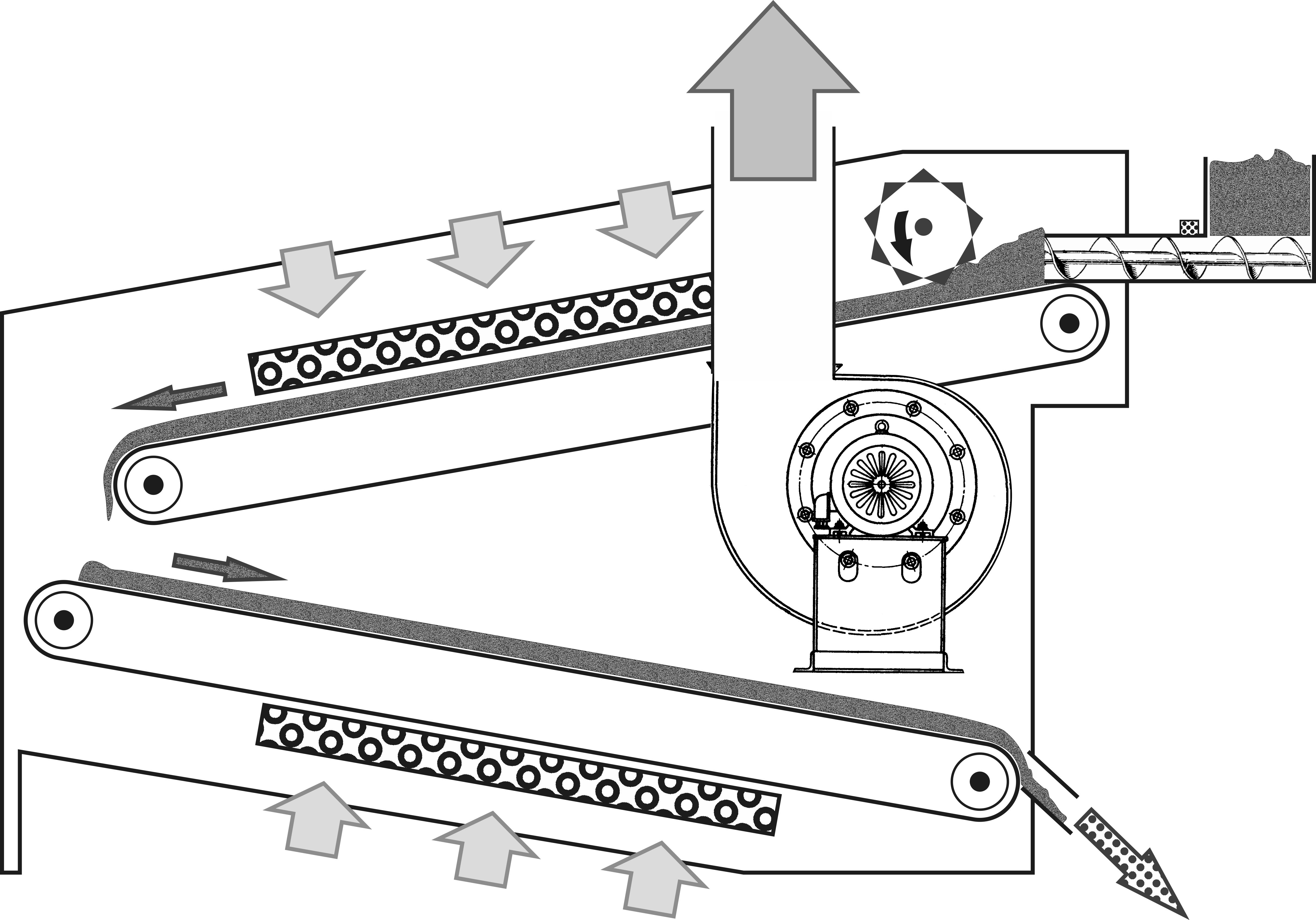

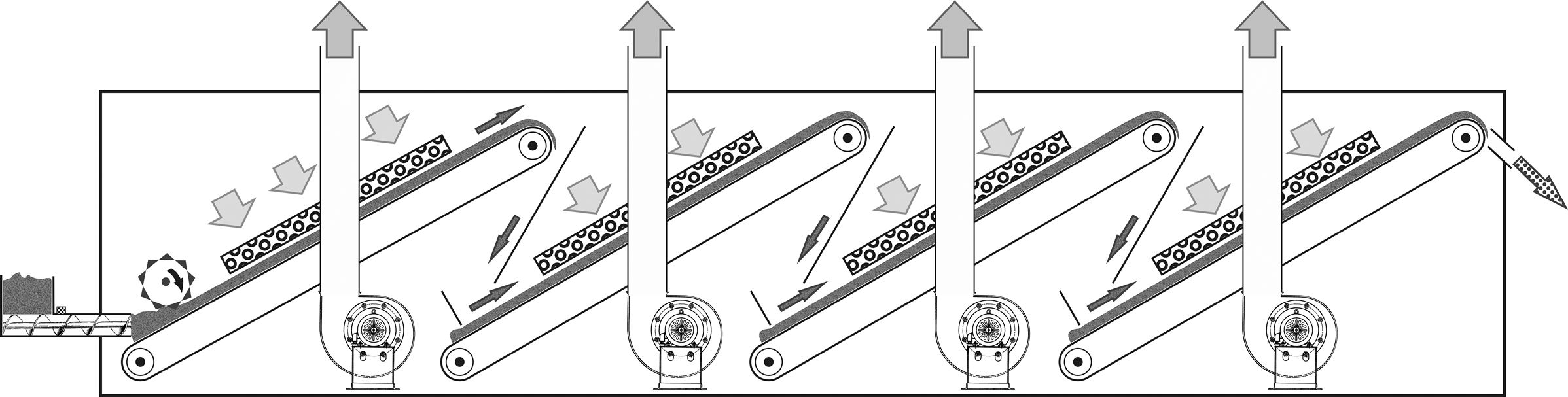

The dryer consists of one or several belt conveyors arranged one above the other. The conveyors are enclosed in a casing, with heaters placed between them if heat is supplied by steam or hot water, or with ducts when a mixture of flue gases is used as the thermal agent.

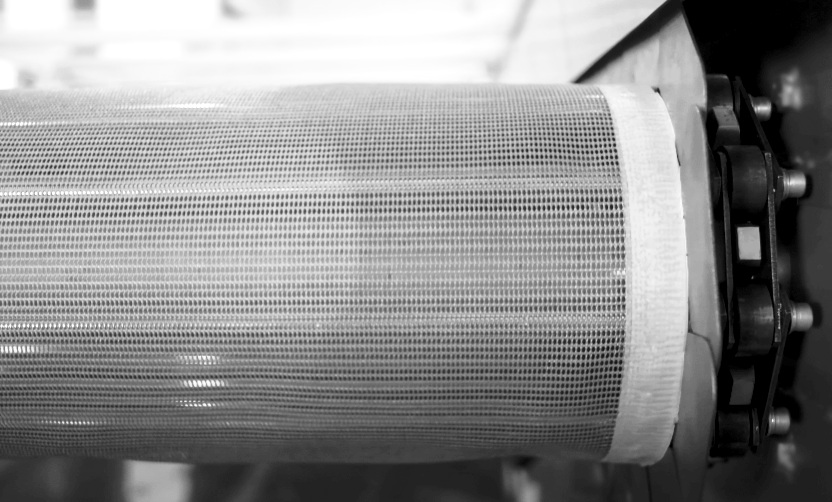

These dryers are often equipped with a pneumatic or hydraulic cleaning system on the lower path of each conveyor, as clogged cells drastically reduce the flow of the agent through the material layer, and contamination spots lead to uneven drying and disrupt further processing technological processes. Nozzles installed on oscillating ramps are used to decrease air or water consumption by tenfold in cleaning applications. Traces from the jets appear as ridges of wavy lines, but within 5-10 belt revolutions, full coverage and a sufficient effect are achieved.

These dryers are often equipped with a pneumatic or hydraulic cleaning system on the lower path of each conveyor, as clogged cells drastically reduce the flow of the agent through the material layer, and contamination spots lead to uneven drying and disrupt further processing technological processes. Nozzles installed on oscillating ramps are used to decrease air or water consumption by tenfold in cleaning applications. Traces from the jets appear as ridges of wavy lines, but within 5-10 belt revolutions, full coverage and a sufficient effect are achieved.

The belt is a mesh with 0.5x0.5 mm (0.02x0.02 inches) or 1x1 mm (0.04x0.04 inches) cells, made from fiberglass-reinforced Teflon (PTFE). The working temperature of the polymer reaches +260°C (500°F), allowing operation across a wide range of thermal agent temperatures. High wear resistance and careful handling make this type of dryer one of the cheapest in terms of consumables. However, attempts to work at extreme temperatures, as well as insufficient cleaning of the material from large and sharp inclusions, can lead to frequent damage to the belt, which cannot be repaired by bonding. Certainly, repairs with inserted pieces and joining with steel clips are possible, yet this process requires high qualification and careful tension adjustment for belts with a width of 1.2-3 meters (4-10 feet).

As an alternative to composite belts, steel meshes or perforated sheet inserts attached to traction or roller chains can be used. The bushings and rollers of the chain should be filled with heat-resistant grease during manufacturing, and when using a traction chain, the support plates along its entire length slide on Teflon guides to reduce load. This variant is more repairable and can be used for drying coarse materials with high bulk density.

To extend the length of the conveyor based on a Teflon belt, a roller chain with rods threaded through the rollers can also be used to carry most of the material load. The belt slightly sags between the resulting grid. This setup complicates tension adjustment and belt cleaning but allows for high moisture operation with fine fractions like brewer's grains. Separating the "drive" part of the belt from the "material-carrying" part reduces corrosion speed or even eliminates it with stainless elements.

Between the belt and the chain, plates are threaded onto the rods, forming a single movable edge to prevent the material from spilling onto the chain. The plates extend over the conveyor flanges, creating a sliding labyrinth seal. This configuration directs the thermal agent through the material layer rather than bypassing the belt. These seemingly minor plate inserts can increase the material layer and dryer capacity significantly, as the mass of material in the warm agent flow grows several times. The increased resistance to the agent flow is compensated by increasing the suction of fans extracting steam from the dryer.

Between the belt and the chain, plates are threaded onto the rods, forming a single movable edge to prevent the material from spilling onto the chain. The plates extend over the conveyor flanges, creating a sliding labyrinth seal. This configuration directs the thermal agent through the material layer rather than bypassing the belt. These seemingly minor plate inserts can increase the material layer and dryer capacity significantly, as the mass of material in the warm agent flow grows several times. The increased resistance to the agent flow is compensated by increasing the suction of fans extracting steam from the dryer.

The thickness of the layer cannot infinitely increase productivity. Each type of raw material has an optimal level at which the thermal agent transfers most of its energy and the median drying rate across all material layers is maximized. For instance, with a very thin layer, the drying rate is at its maximum, and in some experiments with sawdust at an initial moisture content of 50%, drying required less than a minute due to excess heat consumption as the agent exited without cooling. However, a thin layer reduced the amount of material processed through the unit, even at the maximum possible belt speed. Conversely, an overly thick layer nearly halted the drying of layers, as air reached them nearly cooled. With an excessive layer, even very slow belt movement didn’t ensure complete drying of the material, and increasing the flow was already at the fans' capacity limit. Since the aerodynamic resistance of a layer increases non-linearly with flow speed in a porous medium, increasing the flow quickly leads to economic impracticality and complicates the design. For wood mass, the optimal layer thickness limits range from 200 mm (8 inches) for raw sawdust to 500 mm (20 inches) for raw wood chips with particle size up to 50 mm (2 inches) and plate thickness up to 10 mm (0.4 inches). The temperature regime also differs: for sawdust, it can reach 300°C (572°F) with flow speed limitation when naturally moist material is introduced, while for chips, the temperature is lowered to 150°C (302°F) with a 2-3 fold increase in airflow. The smaller the fraction, the greater the contact area and more active heat transfer on the particles' surface due to its larger total area, without needing to heat deep into the wood piece. With larger fractions, the surface area decreases, so the flow speed is maximized to achieve effective amplitude between the surface and the interior of the chips. The temperature is reduced for chips because, with active blowing, individual thin sticks tend to overheat and ignite.

Instead of a Teflon mesh, plates made from perforated sheets can be installed. Typically, perforated sheets are used to make bent parts with a channel-shaped cross-section for rigidity and loops at the ends for attaching to the chain lugs. A cleaning device is installed opposite the driven or drive shaft, where the plates disconnect as they wrap around the sprocket, facilitating their cleaning and preventing particles from getting caught when closing.

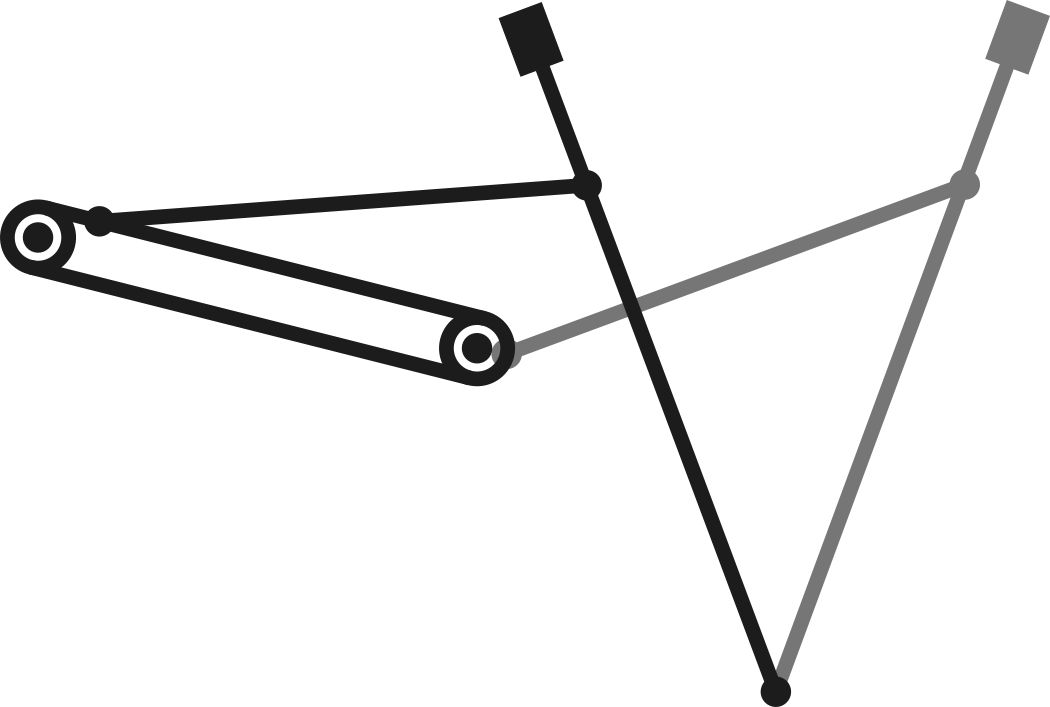

For grain and similar bulk types of raw materials, an oscillating chute around its axis can be used to distribute particles over the belt. With the correctly chosen amplitude and frequency of the distributor for a given linear speed, the laid down "zigzag" path has an impressively uniform thickness. An eccentric-based drive cannot be used to rotate the axis of the chute, as there will be too long a slowdown at the belt edges, and the raw material bands on the belt will not merge smoothly. A chain drive with linkage through silent blocks is a better choice, ensuring relatively uniform angular speed in both directions, and the change of direction takes a short interval, determined by the ratio of half the sprocket's circumference to the distance between the axes of the drive and driven sprockets.

For grain and similar bulk types of raw materials, an oscillating chute around its axis can be used to distribute particles over the belt. With the correctly chosen amplitude and frequency of the distributor for a given linear speed, the laid down "zigzag" path has an impressively uniform thickness. An eccentric-based drive cannot be used to rotate the axis of the chute, as there will be too long a slowdown at the belt edges, and the raw material bands on the belt will not merge smoothly. A chain drive with linkage through silent blocks is a better choice, ensuring relatively uniform angular speed in both directions, and the change of direction takes a short interval, determined by the ratio of half the sprocket's circumference to the distance between the axes of the drive and driven sprockets.

To reduce the load on the drives that move the belt, conveyors are set at a 4° angle, which compensates for a friction coefficient of 0.07, typical for ball bearings or Teflon guides. In this setup, hot air is supplied above the top and below the bottom conveyors, and it is extracted from the space between them. This design is quite popular in the design of grain dryers, where it is important, at a relatively low temperature of the thermal agent, to process the maximum possible mass of material for gentle drying. The temperature regime for drying seed material should not exceed 45°C (113°F), while feed grain is dried at 53-55°C (127-131°F).

To reduce the load on the drives that move the belt, conveyors are set at a 4° angle, which compensates for a friction coefficient of 0.07, typical for ball bearings or Teflon guides. In this setup, hot air is supplied above the top and below the bottom conveyors, and it is extracted from the space between them. This design is quite popular in the design of grain dryers, where it is important, at a relatively low temperature of the thermal agent, to process the maximum possible mass of material for gentle drying. The temperature regime for drying seed material should not exceed 45°C (113°F), while feed grain is dried at 53-55°C (127-131°F).

When drying chips with high initial moisture content and using a chain conveyor or steel mesh, the length of the conveyor is limited by sagging under its own weight and the material's load. Coupled with relatively high drying temperatures, short conveyors with cascading arrangement are used. In this case, a much greater torque is required because all 6-8 conveyors raise the material at an angle. A multi-level layout is also possible, but it excessively complicates installation and maintenance.

Hot air supply is ideally provided over the material, with extraction under the belt. Otherwise, a significant pressure drop can cause a boiling layer and unintended ejection of material with the steam. The directed flow that presses the material to the base also helps reduce air dustiness, as the biomass layer serves as a kind of filter.

Hot air supply is ideally provided over the material, with extraction under the belt. Otherwise, a significant pressure drop can cause a boiling layer and unintended ejection of material with the steam. The directed flow that presses the material to the base also helps reduce air dustiness, as the biomass layer serves as a kind of filter.