The counterflow pellet cooler gained popularity as a mechanical setup that was simple to understand in the mid-1970s when automation was less accessible to primitive agriculture.

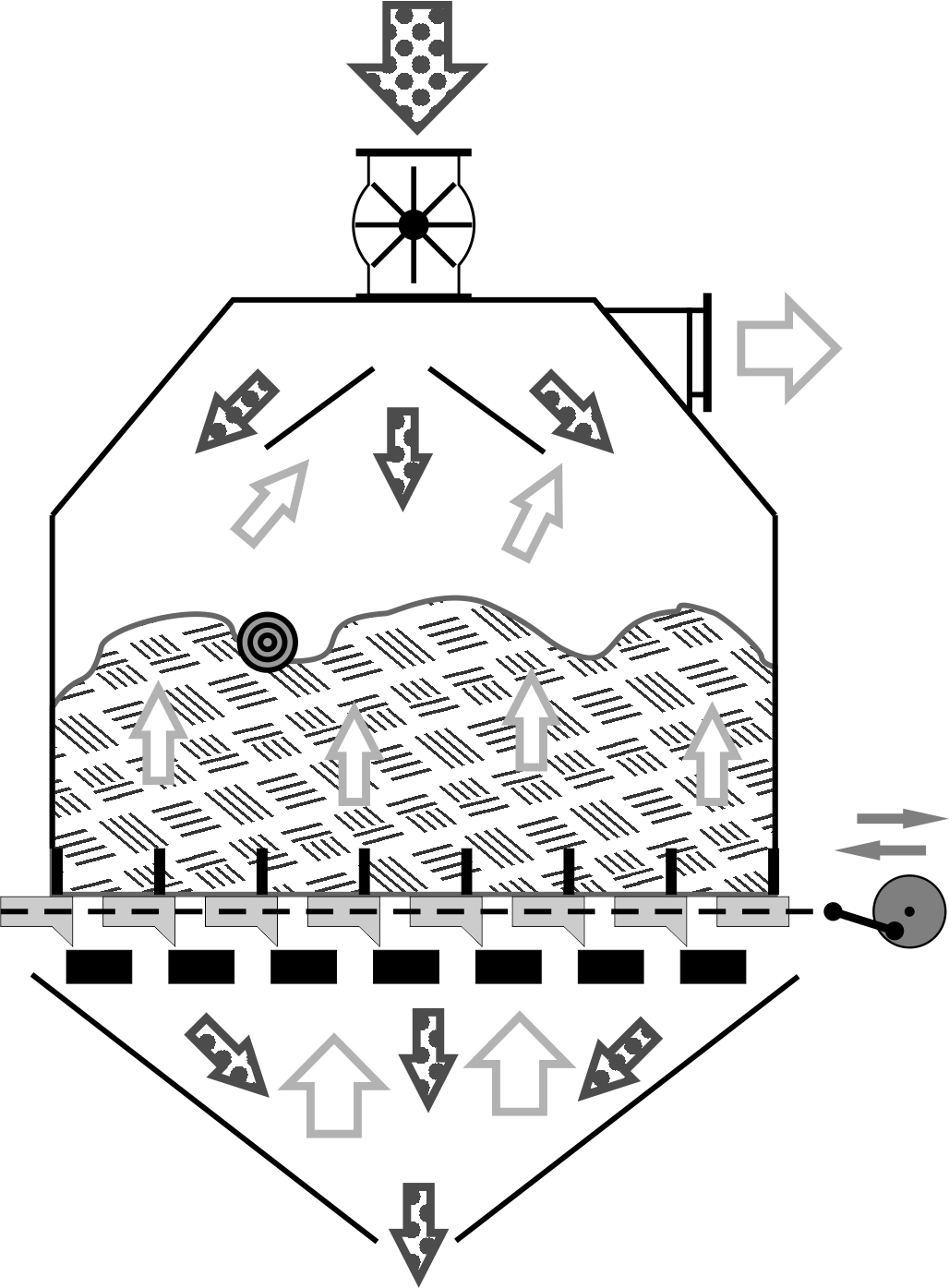

Pellets are fed through a rotary valve into the cooler hopper. Right below the valve, blades are used to divide the flow in multiple directions for relatively even layer distribution. The hopper bottom is equipped with a movable grate with wide flat bars, with gaps between them roughly half their width. Below the movable grate is a fixed grate, offset in such a way that prevents pellets from freely falling through. Beneath the moving bars are protrusions that create space on the lower grate for pellet accumulation when moving left, and push pellets through openings in the lower grate when moving right. Each cycle of movement thus discharges a controlled amount of pellets evenly across the hopper floor. Blades above the movable grate hold the product pile in place, ensuring uniform discharge.

Pellets are fed through a rotary valve into the cooler hopper. Right below the valve, blades are used to divide the flow in multiple directions for relatively even layer distribution. The hopper bottom is equipped with a movable grate with wide flat bars, with gaps between them roughly half their width. Below the movable grate is a fixed grate, offset in such a way that prevents pellets from freely falling through. Beneath the moving bars are protrusions that create space on the lower grate for pellet accumulation when moving left, and push pellets through openings in the lower grate when moving right. Each cycle of movement thus discharges a controlled amount of pellets evenly across the hopper floor. Blades above the movable grate hold the product pile in place, ensuring uniform discharge.

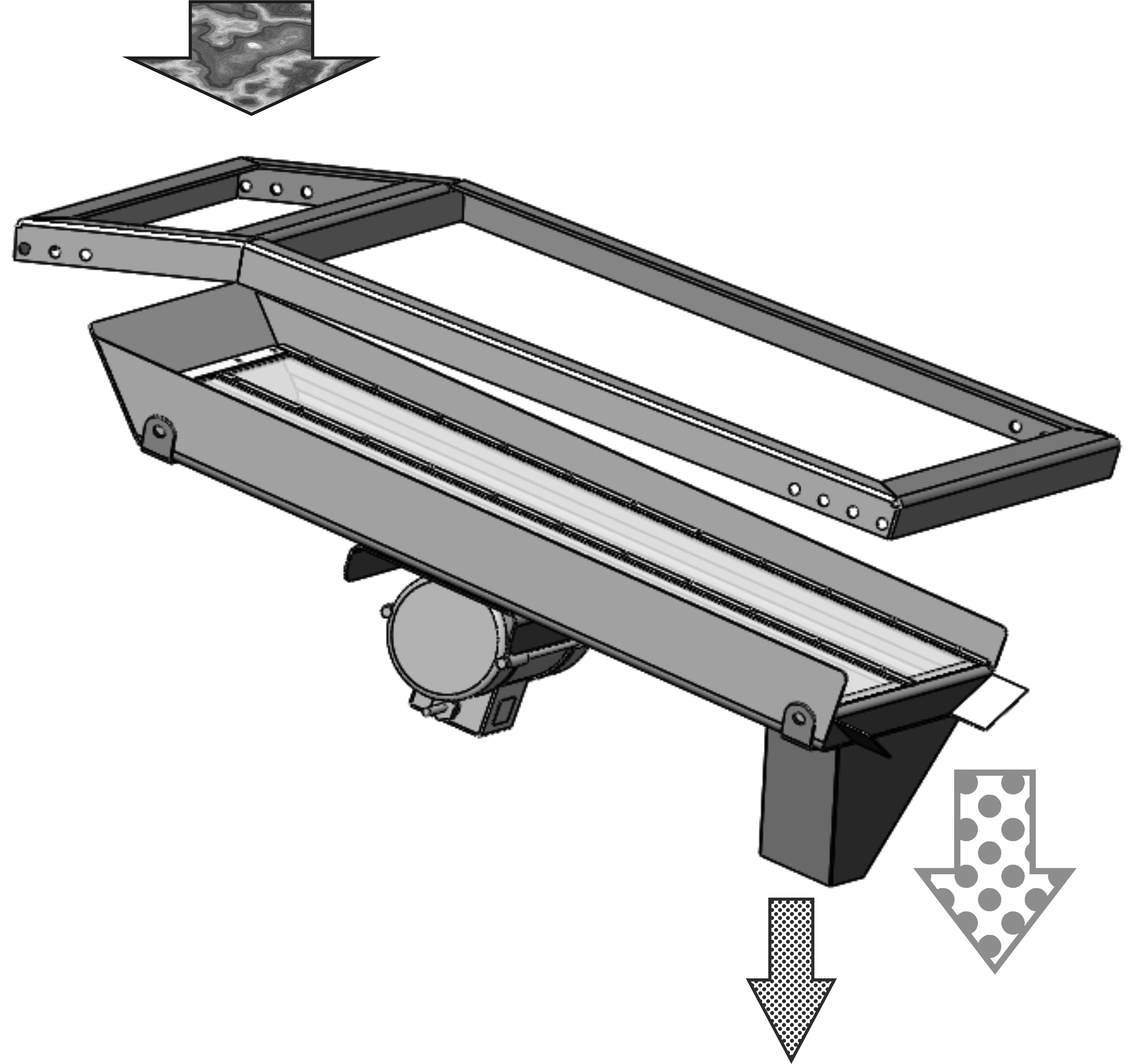

Below the discharge device is a funnel, where pellets drop onto a sieve or belt-scraper conveyor. For capacities up to 5 tons per hour, the sieve is quite simple and compact, usually placed directly below the cooler. For higher capacities, the screening machine is placed adjacent and a conveyor is used to transport the pellets. Sometimes, to minimize costs, the discharge device is omitted, while the lower funnel is made from perforated sheet metal for air penetration. At the funnel exit, a conveyor provides periodic unloading. The downside of this solution is poor flow over the grate, often causing bridging in the funnel and uneven unloading. This increased pellet layer hinders airflow, and small particles fall past the conveyor onto the factory floor.

An aspiration duct with a flange for connection is located at the top of the hopper, creating a vacuum inside. Fresh air moves upward between the grates counter to the pellet flow, significantly enhancing heat exchange efficiency. The flip side of efficiency is less resistance to sticky pellets. Warm and humid air reaches the top layers, insufficient for quick drying, which in some materials leads to clumping and uneven cooling.

The pellet layer level is monitored by a sensor on the hopper's side. Older models featured a blade with a dry contact that controlled the discharge drive. Discharge intensity was adjusted with pulleys of different diameters between the motor and gearbox, allowing the dry contact to activate less frequently while preventing hopper overfill. The frequency of the movable grate's movement is usually 20 to 100 cycles per minute, so the eccentric doesn't require balancing. Increased vibration occurs when the cooler is empty, as its weight is insufficient, but due to the rarity, this issue is minor.

The working height of the granule layer in the cooler hopper is typically between 0.3-0.5 meters (1-1.6 feet). Modern coolers are equipped with either inexpensive inductive level sensors, which function well at positive temperatures, or with rotary paddle sensors that react to shaft stoppage. The latter is the most reliable for pellets and biomass, although it is significantly more expensive. If one sensor is used, it activates unloading for a set interval of time, reducing the granule layer by 10-20%. The discharge rate of the granules, or the oscillation frequency of the moving screen, must ensure an unloading speed with a 20-30% reserve above the pellet mill's output. When using two sensors, a single time relay is insufficient, so a controller is used to maintain the layer height within the range set by the sensors.

The disadvantages of a counterflow cooler go beyond the complexity of manufacturing and maintenance. Rotary valves and the moving screens of the discharge mechanism inevitably lead to pellet damage. The increase in fines due to them is small, but on a scale of months and years, the difference can add up to tens and hundreds of tons.

You Might Also Like

Important! All information on this website is for informational and recommendation purposes only! Before making changes to the settings and structure of the equipment, be sure to consult with the manufacturer, ensure the safety of your actions, and just in case, consider how to return everything to its original state.