In most types of cyclones, particles larger than 200 microns are efficiently settled with a diameter of 500-800 mm (20-30 inches) if the height of the cyclone is at least three times its diameter. Increasing the diameter results in a higher release of dust, especially when the raw material is very dry and particles are less likely to stick together. Reducing the diameter decreases not only the air capacity but also leads to dust accumulation in the lower conical section of the cyclone, particularly when cyclones are used in battery form. Additionally, a diameter that is too small can reduce separation quality when there is a wide range of particle sizes. Larger particles create radial flows when they impact the walls, sending dust back to the center of the cyclone.

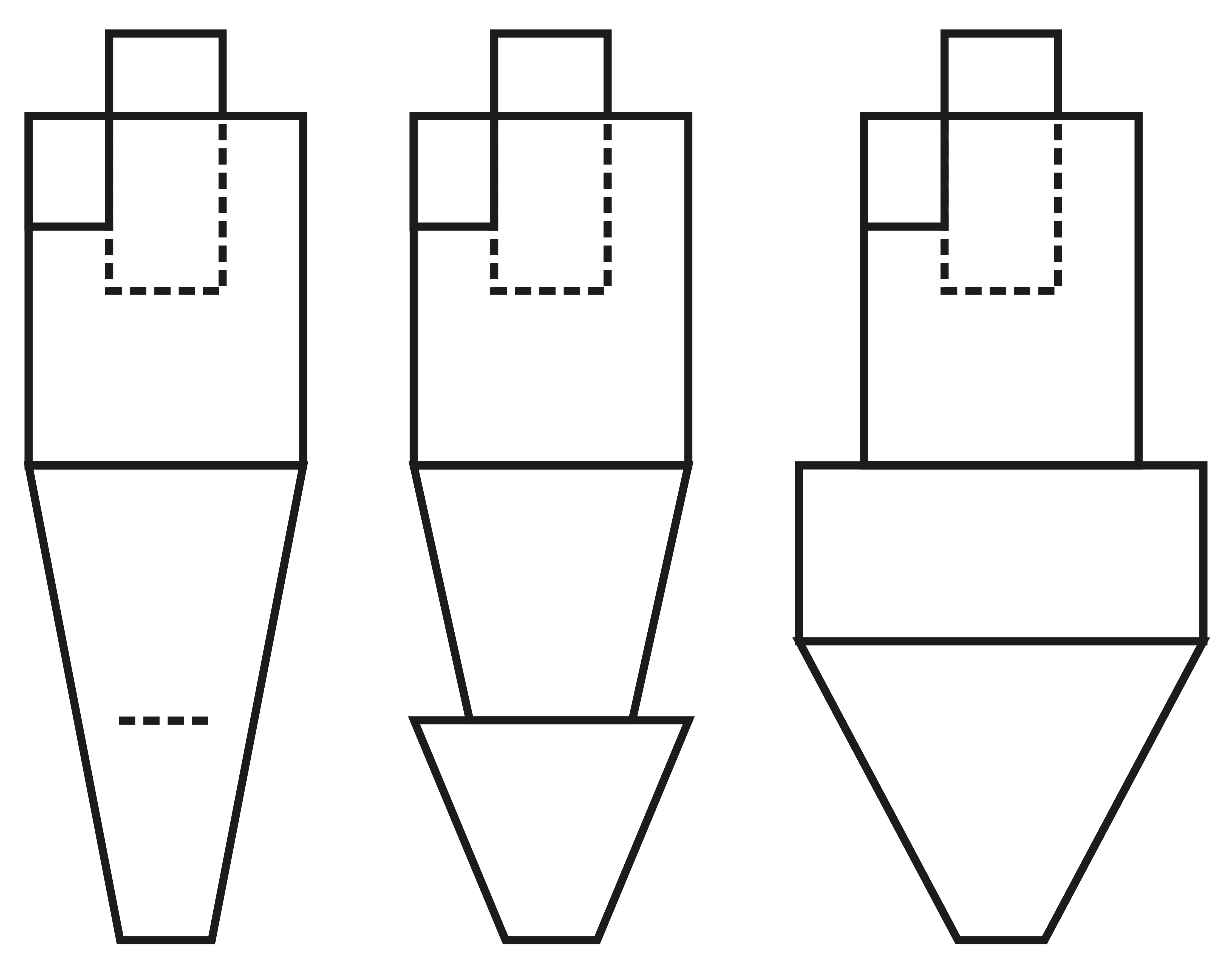

In the production of biofuel and feed pellets, biomass is predominantly used, so dust should be considered at least moderately cohesive. Due to its ability to form a layer in the conical part, most manufacturers recommend limiting dust concentration to 250 g/m³ (0.016 lb/ft³). With a higher feed rate, clumps are caught by the whirlwind, causing discharge into the outlet pipe, which can be managed with varying success by installing a horizontal disk in the center of the cone, shortening the cone with an attached calming conical hopper, or eliminating the conical section entirely in favor of a vertical exit into a pyramidal accumulator hopper.

In the production of biofuel and feed pellets, biomass is predominantly used, so dust should be considered at least moderately cohesive. Due to its ability to form a layer in the conical part, most manufacturers recommend limiting dust concentration to 250 g/m³ (0.016 lb/ft³). With a higher feed rate, clumps are caught by the whirlwind, causing discharge into the outlet pipe, which can be managed with varying success by installing a horizontal disk in the center of the cone, shortening the cone with an attached calming conical hopper, or eliminating the conical section entirely in favor of a vertical exit into a pyramidal accumulator hopper.

There are three main options for organizing pneumatic transport, with the possibility of combining them:

- Use two cyclones sequentially: the first with a small and wide conical section for unloading the main bulk of the material, and the second for final cleaning

- Use an optimally designed cyclone followed by a multi-bag aspiration filter

- Recirculate the system by looping the outgoing air

There are numerous types of cyclones for different purposes, temperatures, and material characteristics. Several types are suitable for capturing fine sawdust or larger wood dust, characterized by common geometric features based on the "golden ratio":

- The cyclone height should be at least three times the diameter

- The height of the conical section should be at least 40% of the total length

- The diameter of the inner tube should be 38% ±5% of the cyclone's diameter

- The external diameter should not exceed 800 mm (31 inches)

- The descent speed of the flow across the horizontal cross-section of the cyclone should be at least 3 m/s (10 ft/s)

- The lower edge of the inner tube should be below the entrance edge by 60-70% of the entrance height to ensure that the main air mass makes nearly a full rotation before exiting the cyclone

When ordering a cyclone, it is quite helpful to provide the flange dimensions of the rotary valve. This ensures that the corresponding parts fit well, making the installation straightforward. But this is not the whole story. The most interesting aspect is that the settling velocity also determines the mass throughput capacity of the lower flange for settled material. In commonly available formulas and reference materials, the values given for wood chips and sawdust are often much higher because they are measured at naturally high moisture content. Additionally, this occurs when a large mass is being unloaded, causing inevitable air acceleration in the same direction. For example, various empirical formulas specify the settling velocity for sawdust in the fraction range of 0.4-1mm (0.016-0.039 inches) from 1.8 to 7 m/s (6 to 23 ft/s). However, in practice, you get values about ten times smaller with a moisture content around 10%. So, with a flange hole diameter of 200mm (8 inches) and speed of 0.2 m/s (0.66 ft/s), a volume of 20 cubic meters (706 cubic feet) may pass through. If we assume the distance between particles is equal to their diameter, only about 2 cubic meters (71 cubic feet) of actual dust will pass, or roughly 400 kg (882 pounds). In reality, quicker settling of sawdust fractions of 2-3mm (0.08-0.12 inches) happens, pushing air upwards with wood dust and resulting in continuous upward dust ejection. This explains the persistent dusting challenge with cyclone collection. As seen in the illustration above, using a second calming cone, its upper entry is 1.5 to 2 times larger in diameter than its exit. This is because the top takes in a dense suspension of mixed particle sizes, while the bottom discharges finally settled material.

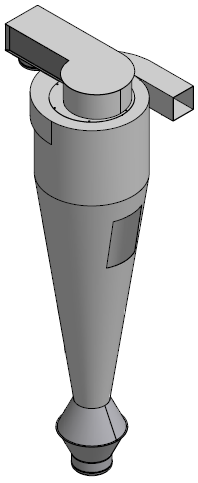

Cyclones with an inlet pipe that makes its first turn at a larger radius than the main body of the cyclone excel at capturing wood flour. In this channel, dust is pressed against the wall in advance, preventing turbulent discharges downward towards the edge of the inner tube. Different countries have varying names for these types of cyclones, but they are easily recognizable by their appearance. A similar effect can be achieved with a standard cyclone by adding a smooth bend in the duct with a rectangular section before it enters the cyclone, turning it at an angle between 90° and 180°. This ensures that the material is pressed against the wall beforehand.

Cyclones with an inlet pipe that makes its first turn at a larger radius than the main body of the cyclone excel at capturing wood flour. In this channel, dust is pressed against the wall in advance, preventing turbulent discharges downward towards the edge of the inner tube. Different countries have varying names for these types of cyclones, but they are easily recognizable by their appearance. A similar effect can be achieved with a standard cyclone by adding a smooth bend in the duct with a rectangular section before it enters the cyclone, turning it at an angle between 90° and 180°. This ensures that the material is pressed against the wall beforehand.