The simplest method for drying relatively homogeneous fine material that does not tend to stick to working parts is active blowing with hot gases while simultaneously mixing. The creation of such a gas mixture, called a "drying agent", is described in detail in the "Heat Generation" section. Essentially, dryers differ in methods of mixing and moving the material, and it dries in almost all cases by receiving heat from the blown agent both by direct contact and through the heated parts of the dryer's working elements and body. Sometimes, reheated air or liquid is used as a heat carrier, but these options are used much less frequently due to low drying efficiency or the high cost of equipment.

It is possible to adjust the moisture content of the material at the outlet in two ways:

- regulating the heat generator's power by changing the temperature or volume of the drying agent

- regulating the feed rate of the material into the dryer

Combining these methods is only possible when using a controller where all possible operating modes need to be programmed, which is practically an unattainable task for small production facilities and heterogeneous material. Continuous temperature changes at the dryer inlet will struggle with the inertness of the heat generator. Furthermore, the amplitude of temperature fluctuations can reach significant values, and such a mode is highly undesirable for the heat generator's lining, as temperature differences quickly destroy the refractory lining and lead to fatigue cracks on the connecting flanges of the air ducts. Changing the amount of thermal agent has a gentler effect on the heat generator's temperature regime but also has its limitations and ultimately leads to significant temperature changes in the furnace.

Due to the aforementioned drawbacks, the most popular method is regulating the material feed. With a stable temperature and amount of drying agent at the dryer's entrance, it is assumed that a stable amount of water evaporates every hour of operation. By increasing or decreasing the material feed, we can respectively obtain more or less residual moisture in it.

The calculation of energy consumption for drying consists of several components:

- The specific heat of vaporization is 2 MJ/kg (4700 BTU/lb), which means that to evaporate 1 ton of water from material with 55% moisture to achieve 1 ton with 10% moisture, 2000 MJ (1,894,500 BTU) is required

- Since the material needs to be heated to at least 70°C (158°F) before drying begins to allow active evaporation from its surface, the initial 2 tons of wet material when heated from 0°C (32°F) will require an additional (1000*4.2*70+1000*1.56*70)/1000 = 403.2 MJ (382,087 BTU)

- If the material was frozen, an additional 330 MJ (312,000 BTU) is needed to melt 1 ton of water.

Thus, depending on the season, heat expenditure can vary by nearly a factor of 1.5, and dryer productivity decreases by the same factor, as its ability to transfer heat to the material is limited. Of course, it's not always necessary to heat the material so much, and in some modes, the material exits significantly colder than the drying agent, which can occur with a high volume of blown air with extremely low initial moisture. The material may dry out more in summer, or moisture may freeze out in winter, so calculations usually focus on the energy of evaporation for a given initial moisture content, disregarding other factors as temporary or simply adding a 25% productivity reserve for average annual indicators.

Let's conduct further calculations using specific models. The most common scenario involves the drying agent entering the dryer at about 300°C (572°F) and exiting at around 100°C (212°F). This means the heat generator needs to raise the ambient air temperature by 300 degrees, allowing the air to transfer its heat and subsequently decrease by 200 degrees. This process represents the main efficiency loss, which in this case reaches a limit of 67%. So, to obtain 2,000 MJ of energy from raw material, 3,000 MJ must be supplied to the dryer over 3,600 seconds, which corresponds to 833 kW of thermal power. With a 25% reserve, a well-known simple formula emerges: for a capacity of 1 ton per hour of dry sawdust from natural moisture, a heat generator with a power of 1 MW is needed.

This is, of course, a basic calculation intended for initial understanding. Efficient dryers rarely exceed an exit temperature of 70°C (158°F), and the input temperature can reach up to 400°C (752°F). In winter, up to 10% of heat may be lost in uninsulated ducts, on the surfaces of the dryer, and in spark-catcher cyclones. Then, the efficiency becomes (400°C - 70°C)/400°C *100% - 10% = 72.5%. In summer, with raw material moisture below 30%, there is a high risk of ignition, so the intake temperature into the dryer is kept between 150–200°C (302–392°F), with 40–50°C (104–122°F) at the exit, resulting once again in an efficiency around 70%. Very few dryers can handle a heat agent input temperature of 500°C (932°F) or even 700°C (1292°F) without accelerated wear and damage. Often, such cases are the result of incorrect temperature measurement, where the sensor is placed before the cold air mixing or at the top of the duct, where temperature differences in the flow are evident.

Several methods are used to move material inside the dryer:

- Pneumatic – almost continuous levitation with brief lodgments in the labyrinths of the internal structure

- Flow displacement, where each mixing rotation moves the material closer to the exit

- The gravitational method is achieved by installing the dryer at an incline or vertically, so vibrations or mixers drop the material towards the lower exit

- Mechanical – through the installation of spiral-shaped inserts, screws, or grid conveyors

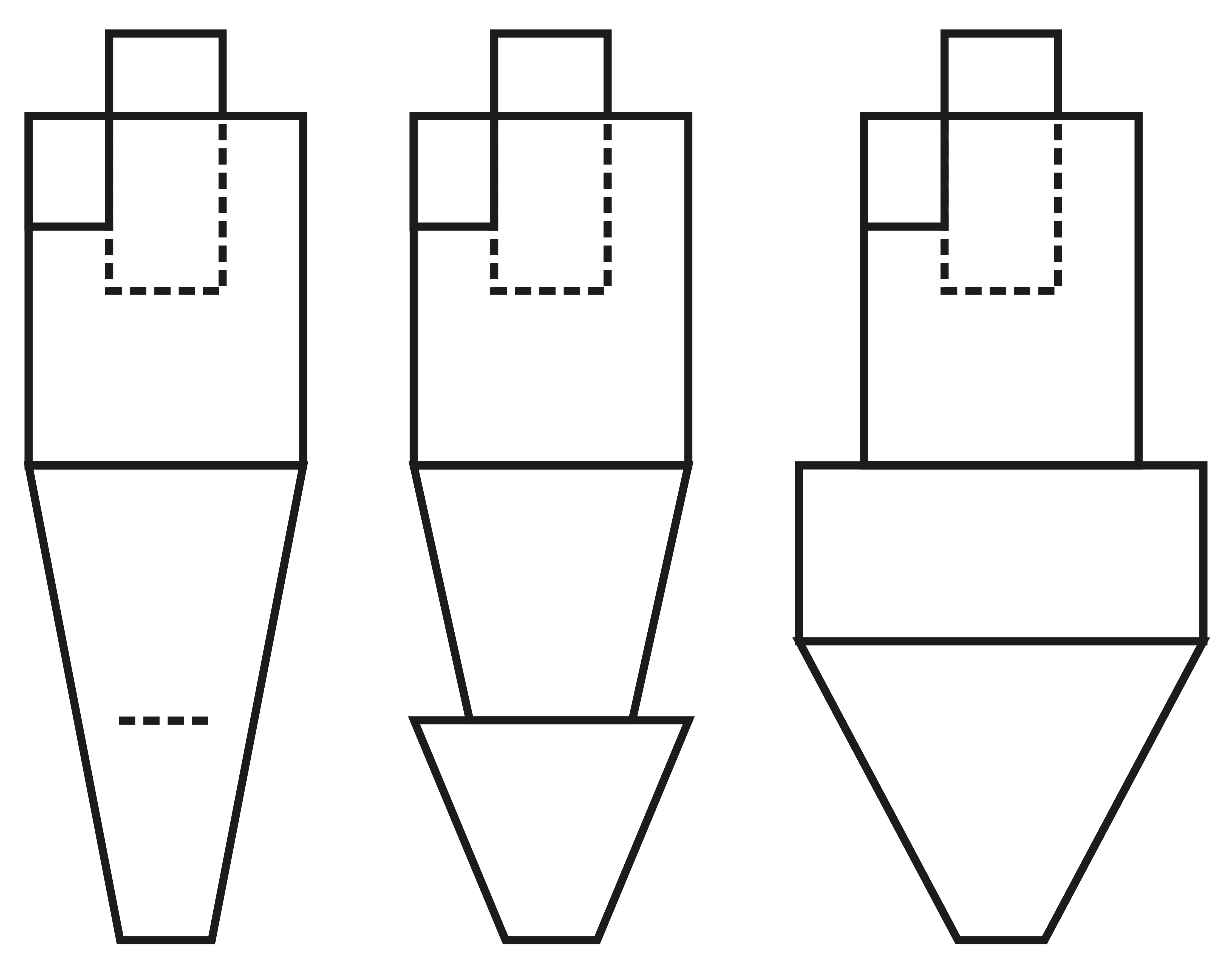

Depending on the predominant method and main mechanism, dryers are classified as drum, rotary, belt, aerodynamic, drying mills, tube, and others.