The development of brushless synchronous electric drives is advancing rapidly, not only in the market for drones and electric transport but also in replacing gear-driven systems with direct drives. Asynchronous motors are limited to 600-700 revolutions per minute because, with such stator coil arrangements, it becomes challenging to produce rhythmic magnetization of the squirrel-cage rotor. For lower speeds, stators must be physically divided into several separate parts with independent magnetic circuits, significantly increasing production costs and reducing motor efficiency. The significant reduction in the price of electronics that control synchronous motors and the availability of neodymium magnets tipped the scales towards synchronous motors, as the assembly of an asynchronous motor with a gearbox has, in some cases, become more expensive than the production cost of a synchronous motor.

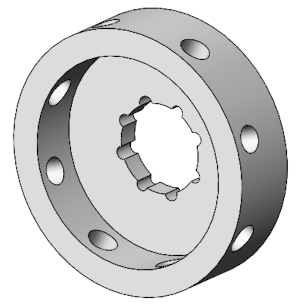

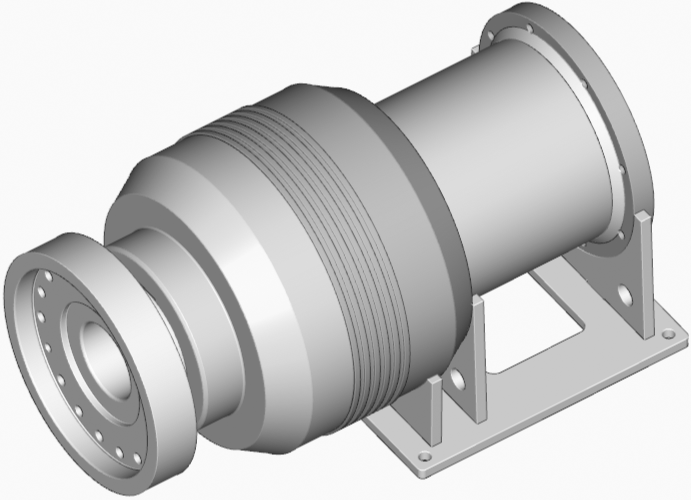

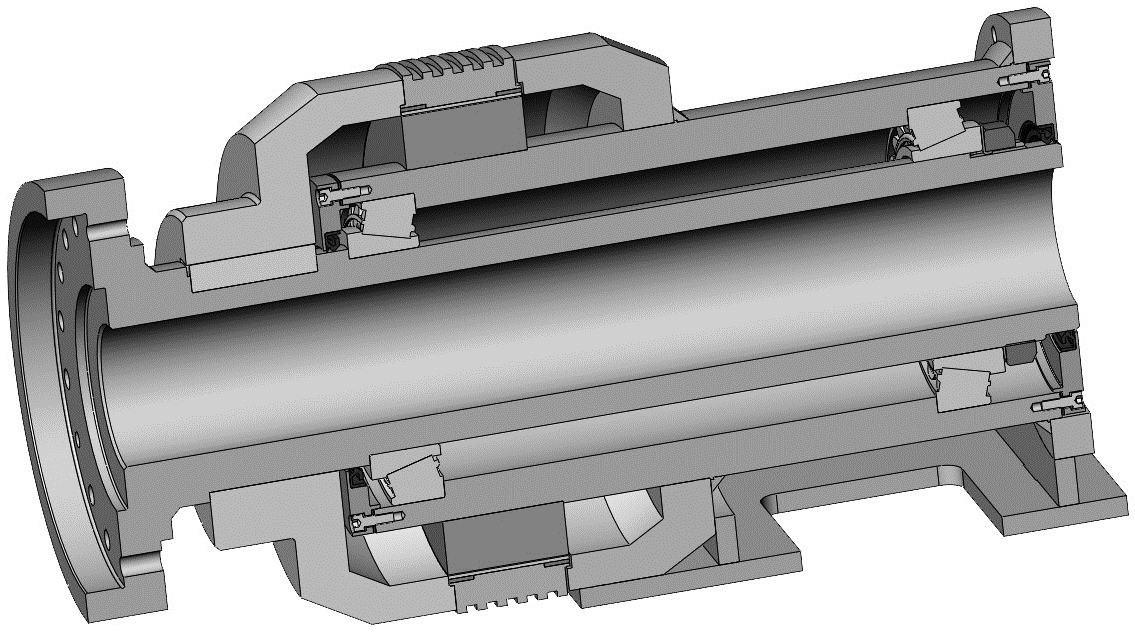

If we compare it with a pellet mill based on a serial gearbox, a common component remains the hollow low-speed shaft. The hole in it is also large enough to house the stationary shaft that holds the rollers. Instead of the largest gear or massive pulley, the aluminum rotor is attached to the platen, in which rows of neodymium magnets are fixed in the specified pole sequence. On the back of the stator, there are holes for mounting protective devices and elements of the cooling system. This design eliminates the most problematic parts of the machine related to reducing speed and increasing torque – gears and pulleys. The number of drive bearings is reduced to just two, which, with their large diameters and low speeds, can last the machine's lifetime without replacement, especially when using tapered roller bearings with adjustment capabilities.

If we compare it with a pellet mill based on a serial gearbox, a common component remains the hollow low-speed shaft. The hole in it is also large enough to house the stationary shaft that holds the rollers. Instead of the largest gear or massive pulley, the aluminum rotor is attached to the platen, in which rows of neodymium magnets are fixed in the specified pole sequence. On the back of the stator, there are holes for mounting protective devices and elements of the cooling system. This design eliminates the most problematic parts of the machine related to reducing speed and increasing torque – gears and pulleys. The number of drive bearings is reduced to just two, which, with their large diameters and low speeds, can last the machine's lifetime without replacement, especially when using tapered roller bearings with adjustment capabilities.

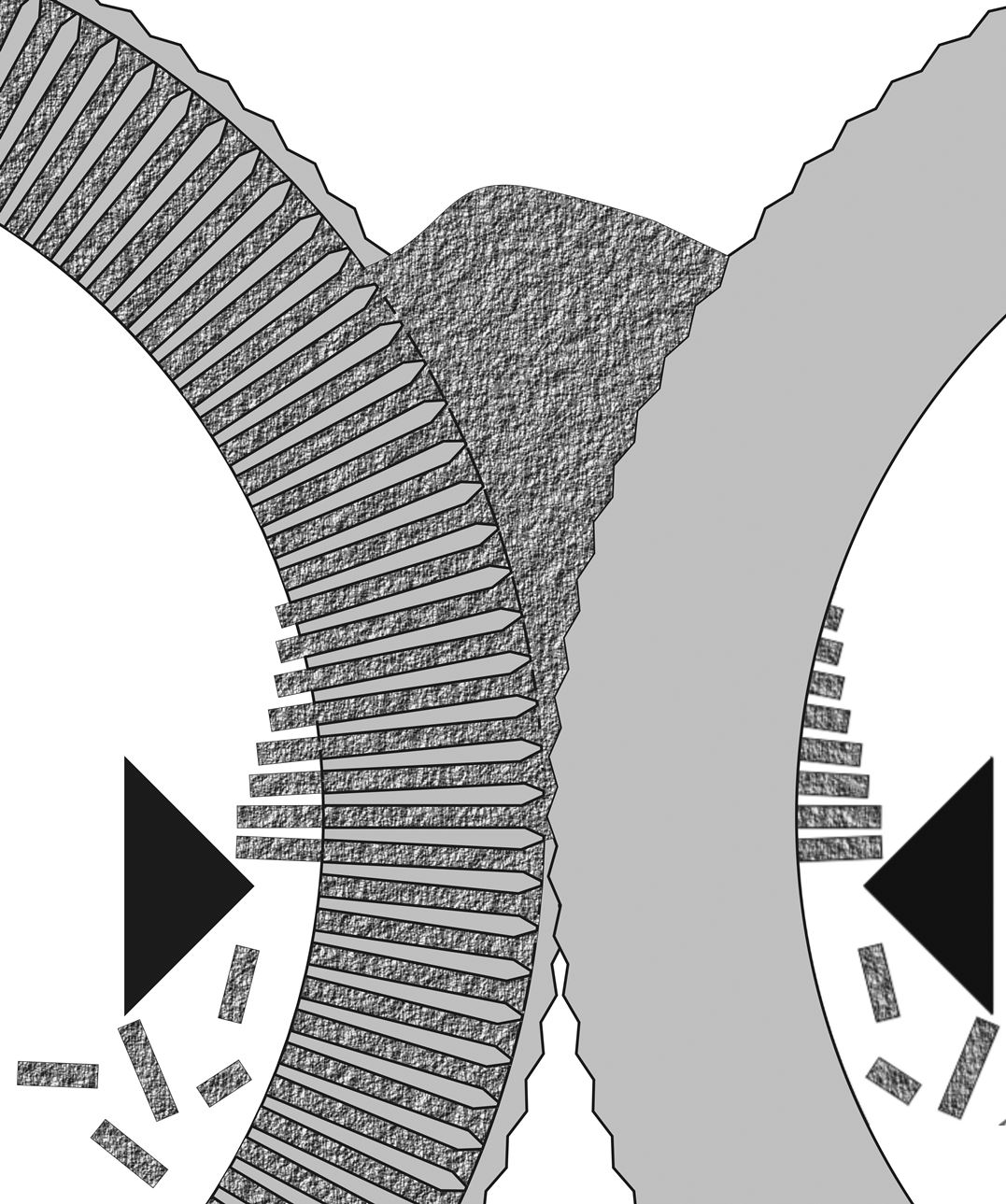

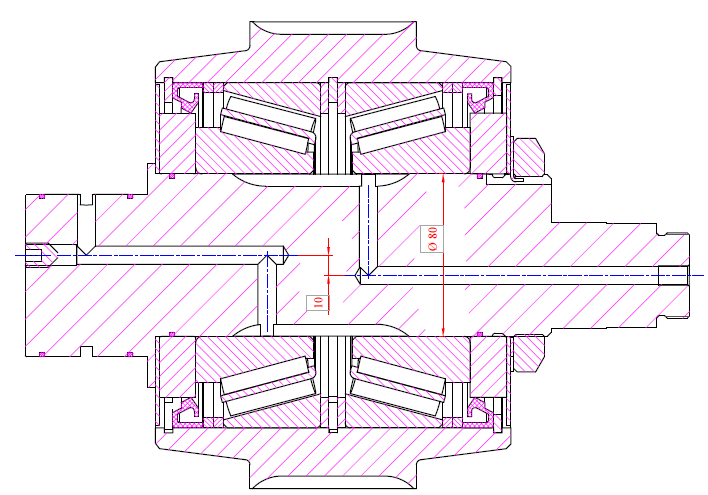

The sketch shows diagrams of a 110 kW (147 hp) pellet mill drive. To create a 220 kW (295 hp) pellet mill, it is sufficient to increase the diameter of the hollow shaft by 1.5 times and mount two rotors with magnets on it. Thus, the drive becomes universal across major components for two models of pellet mills in the most popular market segment.

The sketch shows diagrams of a 110 kW (147 hp) pellet mill drive. To create a 220 kW (295 hp) pellet mill, it is sufficient to increase the diameter of the hollow shaft by 1.5 times and mount two rotors with magnets on it. Thus, the drive becomes universal across major components for two models of pellet mills in the most popular market segment.

Low speeds do not allow the use of passive blades on the shaft for cooling the motor with airflow. A popular solution is liquid cooling of the stator, as the most reliable option for preventing overheating and the most challenging in maintenance. A simple alternative is a sufficiently powerful fan to blow pre-filtered air through the motor, as successfully implemented in belt-driven systems. Excessive pressure inside the housing ensures protection from external dust, safeguarding the windings and bearings.

The use of a controller allows speed regulation, optimizing the pelletizing process for various raw materials. With sufficient current and cooling reserves, short-term overloads are managed just as effectively as with a gear-driven system, but with significantly reduced vibration and noise impact.

Direct drive pellet mills have been launched into mass production by German and Swiss companies, with motor powers ranging from 320 to 580 kW (429 to 778 hp). Their price is currently 2-3 times higher than brands with gear drive systems. The markup is undoubtedly justified by increased working hours due to reduced downtime for maintenance, and overall longevity. When asked about the prospects for compact models for small businesses, the response is that the pricing becomes unjustifiably high. This market segment remains unoccupied, with increasing opportunities for its saturation.