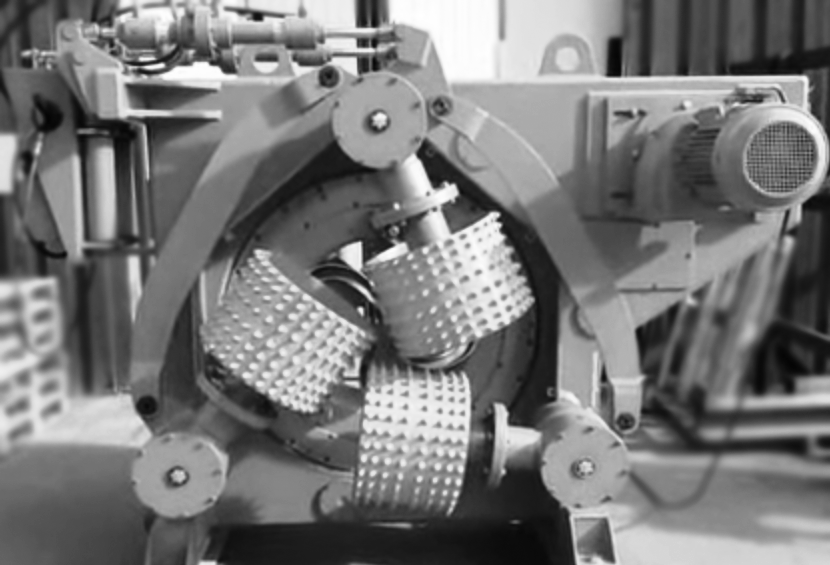

Disc separators are used to separate large fractions of relatively moist and fibrous, yet friable raw material. These devices consist of several shafts with disks mounted on them, all aligned in a single plane and rotating in the same direction. The distance between the disks is chosen so that large pieces travel to the very edge, while smaller particles fall through and are carried away by a conveyor. These systems are effective for separating large sticks from wood chips and for removing large chunks of bark from sawdust. They are sometimes used to shake off boards and slabs from sawdust and wood fibers.

Disc separators are used to separate large fractions of relatively moist and fibrous, yet friable raw material. These devices consist of several shafts with disks mounted on them, all aligned in a single plane and rotating in the same direction. The distance between the disks is chosen so that large pieces travel to the very edge, while smaller particles fall through and are carried away by a conveyor. These systems are effective for separating large sticks from wood chips and for removing large chunks of bark from sawdust. They are sometimes used to shake off boards and slabs from sawdust and wood fibers.

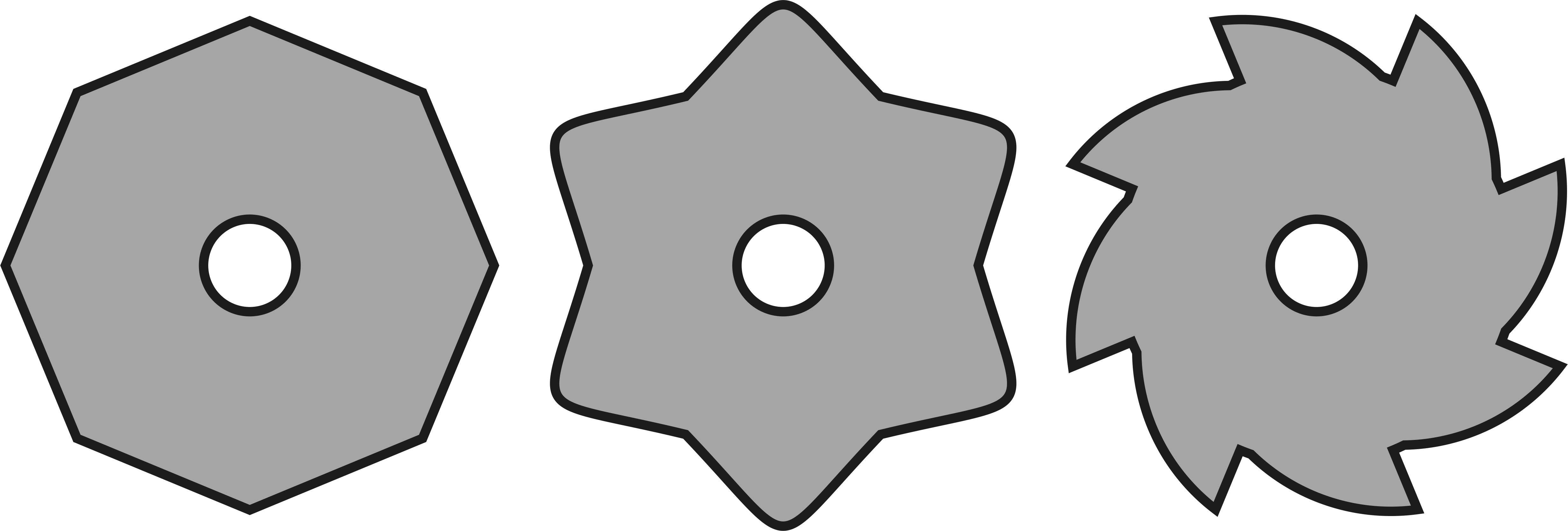

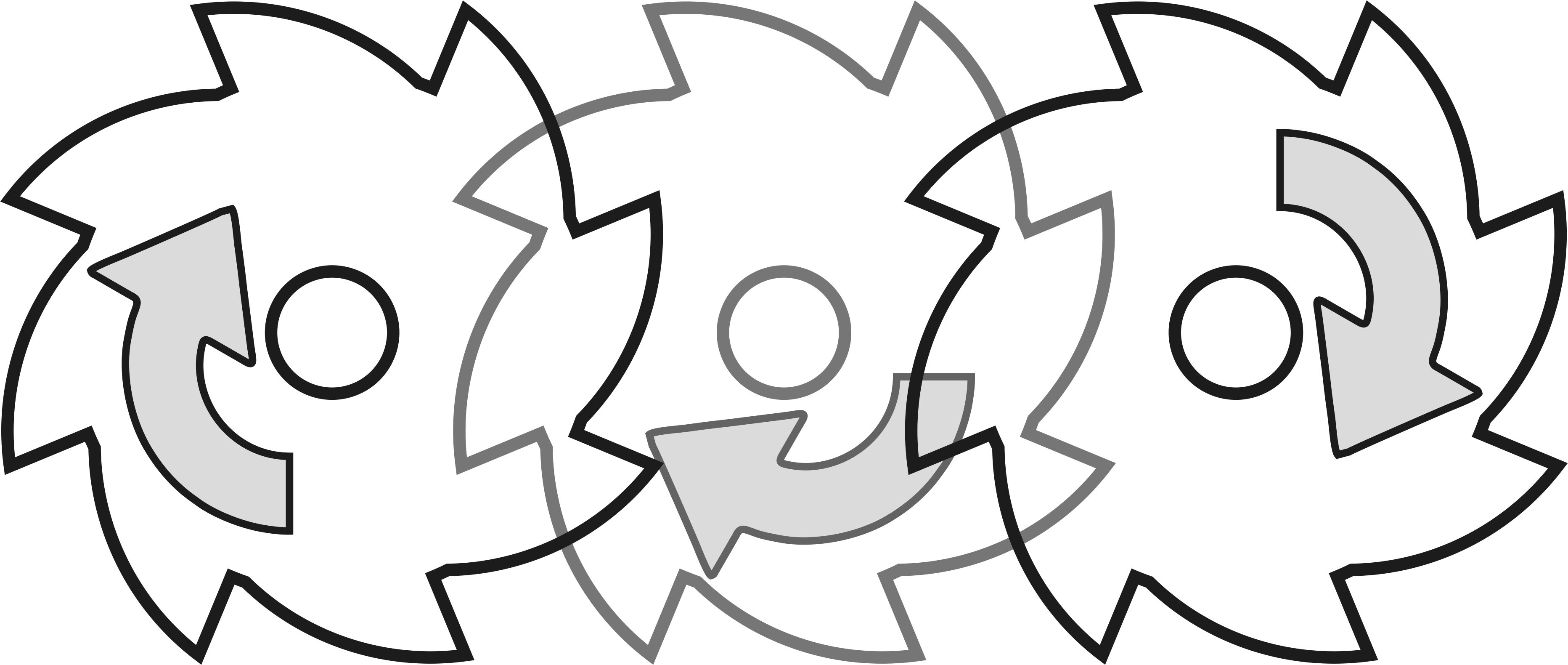

The shape of the disks and their rotation speed are selected based on the specific type of raw material and impurities, although the device is generally universal. A disk with an edge in the form of a regular octagon is most popular for cleaning sawdust, as it allows the plates to be set at a minimal distance from each other. As a result, only the finest fractions pass through the separator, but the throughput decreases significantly. It's necessary to greatly increase the length of the path by adding more shafts and increasing the costs for cutting the disks. Material sifts much better on plates shaped like a hexagonal star with rounded tips. The projections toss up chips and pieces, helping to break frozen clumps and shake sawdust off logs. However, these projections, if the plates are too close, can cause jams from entangled fibers and bast strands. For clearing gaps of particles and fibers, a sawtooth edge with six or eight teeth and reverse rotation is most suitable. Chips stuck between the disks slide along the rounded hump of the tooth and are expelled outside. If mistakenly, rotation is organized in the opposite direction, the flat part of the tooth jams on the first stick that hits the separator's surface. Interestingly, optimally rotating sawtooth disks can toss fibers and sticks upward that are 3-5 times smaller in thickness than the gap between the plates.

The shape of the disks and their rotation speed are selected based on the specific type of raw material and impurities, although the device is generally universal. A disk with an edge in the form of a regular octagon is most popular for cleaning sawdust, as it allows the plates to be set at a minimal distance from each other. As a result, only the finest fractions pass through the separator, but the throughput decreases significantly. It's necessary to greatly increase the length of the path by adding more shafts and increasing the costs for cutting the disks. Material sifts much better on plates shaped like a hexagonal star with rounded tips. The projections toss up chips and pieces, helping to break frozen clumps and shake sawdust off logs. However, these projections, if the plates are too close, can cause jams from entangled fibers and bast strands. For clearing gaps of particles and fibers, a sawtooth edge with six or eight teeth and reverse rotation is most suitable. Chips stuck between the disks slide along the rounded hump of the tooth and are expelled outside. If mistakenly, rotation is organized in the opposite direction, the flat part of the tooth jams on the first stick that hits the separator's surface. Interestingly, optimally rotating sawtooth disks can toss fibers and sticks upward that are 3-5 times smaller in thickness than the gap between the plates.

The diameter of the disks for wood waste separation is usually around 200mm (8 inches). Generally, the diameter does not exceed 3-4 times the average size of the large pieces being separated. The shaft diameter is 35-50mm (1.5-2 inches), depending on the working width of the separator, which ranges from 0.5 to 1.5 meters (2-5 feet). The steel thickness for the disks is at least 3mm for toothed designs and at least 2mm for octagonal shapes. The optimal rotation speed is chosen based on the disk diameter and should provide centrifugal acceleration no more than half of the gravitational acceleration, which for a 200mm (8 inches) diameter means 60-70 rpm. Increasing the speed enhances the shaking effect, but sawdust becomes much harder to pass between the disks and ends up as waste with debris. Reducing the speed below optimal proportionally decreases the throughput of the device.

The diameter of the disks for wood waste separation is usually around 200mm (8 inches). Generally, the diameter does not exceed 3-4 times the average size of the large pieces being separated. The shaft diameter is 35-50mm (1.5-2 inches), depending on the working width of the separator, which ranges from 0.5 to 1.5 meters (2-5 feet). The steel thickness for the disks is at least 3mm for toothed designs and at least 2mm for octagonal shapes. The optimal rotation speed is chosen based on the disk diameter and should provide centrifugal acceleration no more than half of the gravitational acceleration, which for a 200mm (8 inches) diameter means 60-70 rpm. Increasing the speed enhances the shaking effect, but sawdust becomes much harder to pass between the disks and ends up as waste with debris. Reducing the speed below optimal proportionally decreases the throughput of the device.

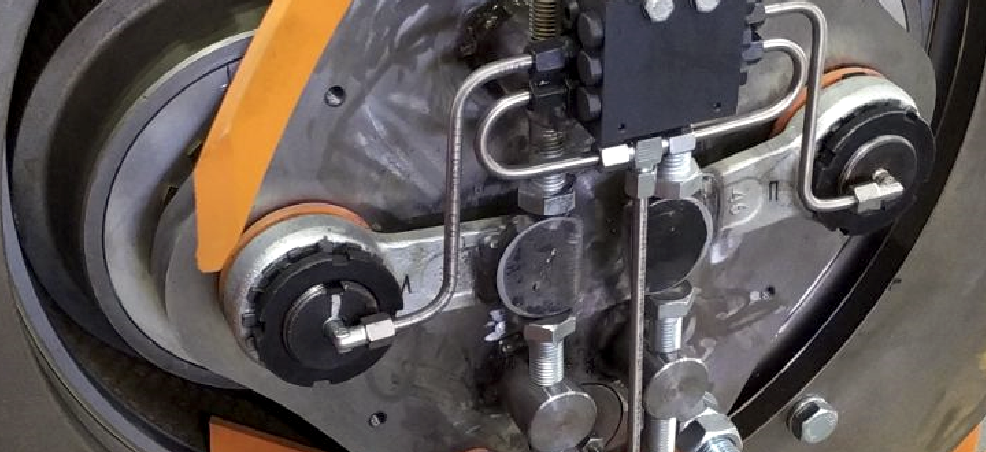

The most economical way to manufacture a disc separator is to sequentially weld CNC-cut discs onto a round calibrated rod, applying intermittent welds on just one side. There is no need to turn the round bar on a lathe since the bearing and chain sprockets are selected to fit the same diameter. The chain sprockets can also be cut from a sheet without hardening and attached with 2-3 weld tacks using the most common drive chain size in the region because the rotational forces involved are minimal. Of course, if the budget allows, it is preferable to use hardened sprockets mounted on a taper bush. For better coverage of driven sprockets, it is convenient to use tensioner sprockets, which consist of a sprocket, a bearing inside it, and a bolt with partial threading serving as the axle for the inner race. Such sprockets are often used in agricultural machinery and are usually an inexpensive consumable in tractor parts stores. It is highly discouraged to use tensioners with plastic sliding pads as they wear out too quickly due to biomass particles.

The most economical way to manufacture a disc separator is to sequentially weld CNC-cut discs onto a round calibrated rod, applying intermittent welds on just one side. There is no need to turn the round bar on a lathe since the bearing and chain sprockets are selected to fit the same diameter. The chain sprockets can also be cut from a sheet without hardening and attached with 2-3 weld tacks using the most common drive chain size in the region because the rotational forces involved are minimal. Of course, if the budget allows, it is preferable to use hardened sprockets mounted on a taper bush. For better coverage of driven sprockets, it is convenient to use tensioner sprockets, which consist of a sprocket, a bearing inside it, and a bolt with partial threading serving as the axle for the inner race. Such sprockets are often used in agricultural machinery and are usually an inexpensive consumable in tractor parts stores. It is highly discouraged to use tensioners with plastic sliding pads as they wear out too quickly due to biomass particles.

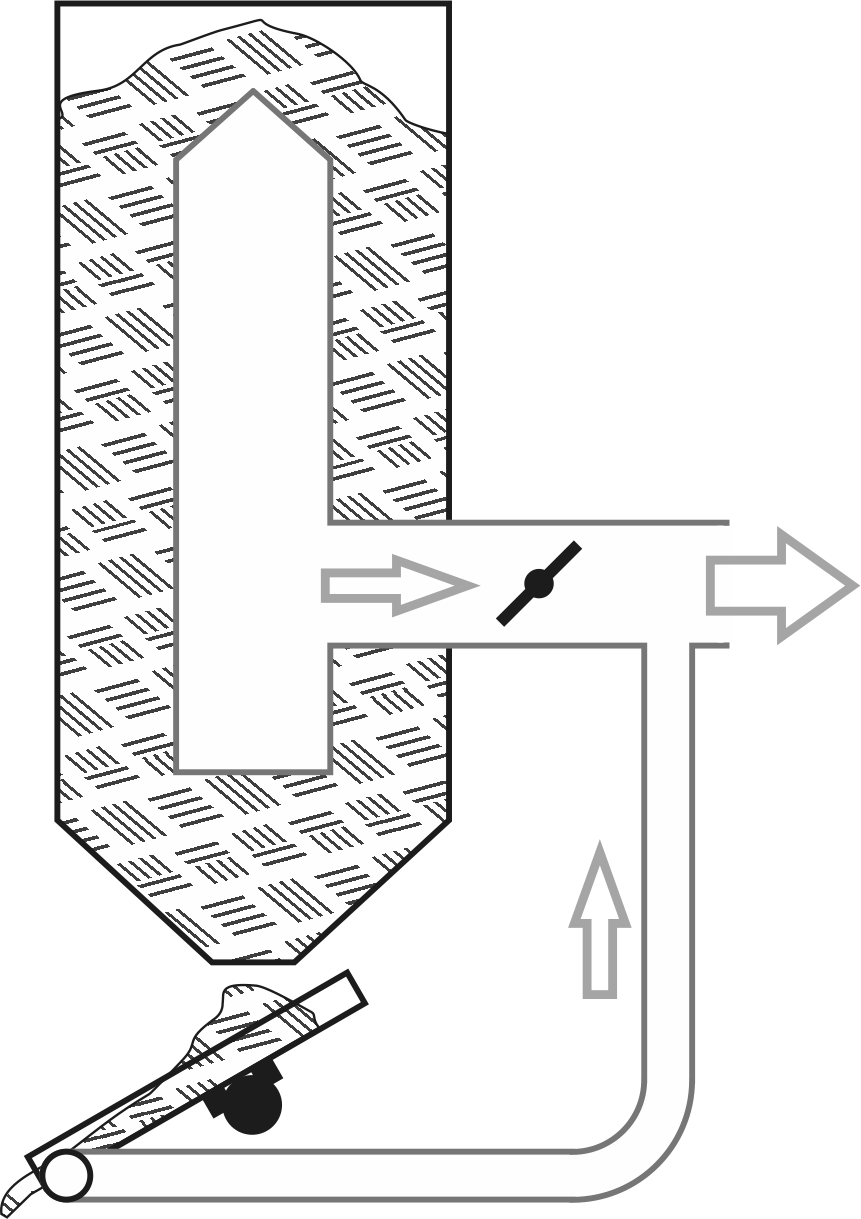

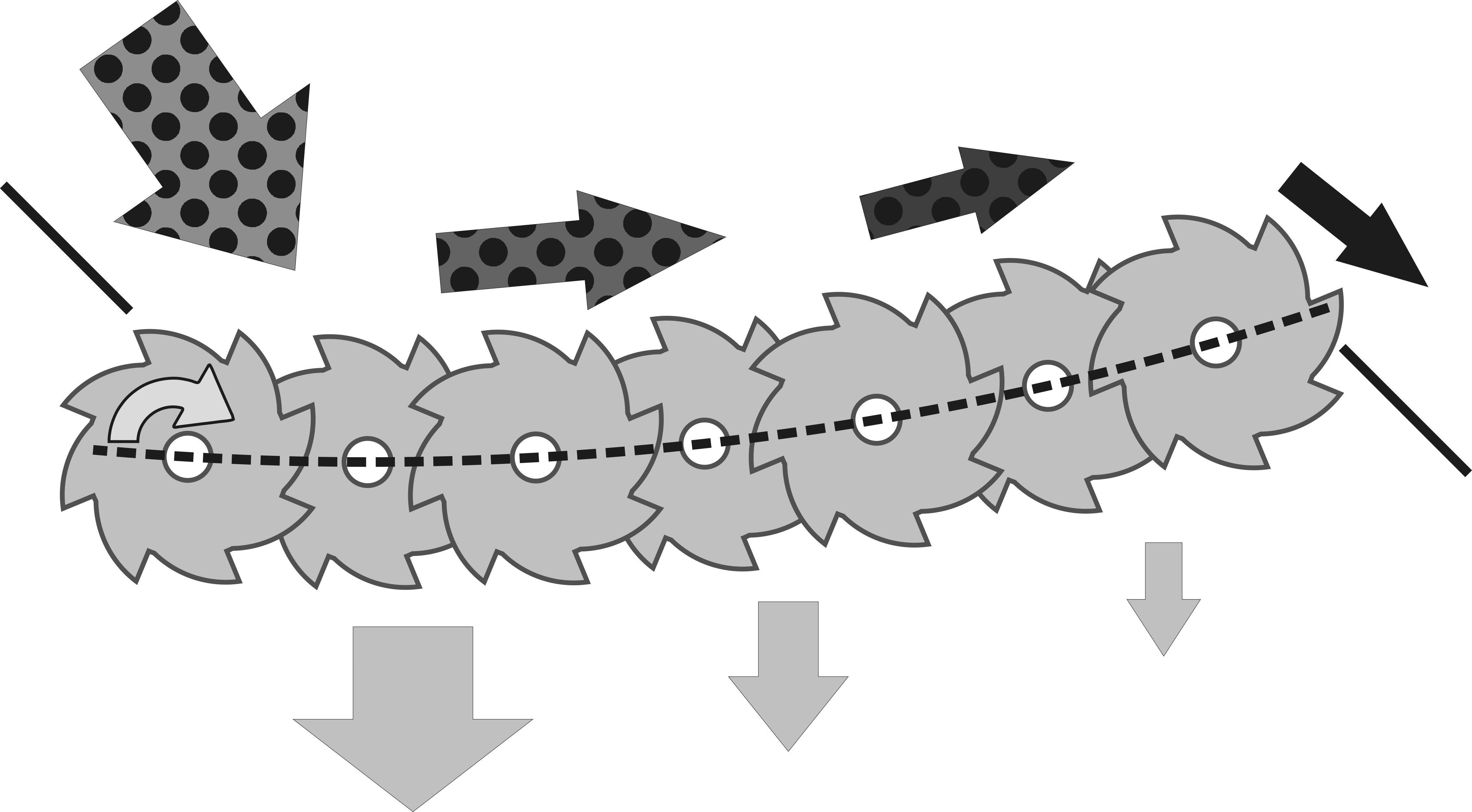

If a disc separator is already installed in the production line but its efficiency is insufficient for quality separation, a good way to increase performance is to add a reverse incline of 10-15°. The material will crawl up the discs, and its shaking time will increase by about 1.5 times. When manufacturing a separator for use in a confined space, axles are initially arranged in an arc so that the bulk of the sawdust falls through on the nearly horizontal shafts at the front, while large pieces get time to be retained, flipped several times, and fully cleaned on the last 3-4 assemblies. It is useful to add an adjustment mechanism to the holder design to select the optimal angle for any raw material.

If a disc separator is already installed in the production line but its efficiency is insufficient for quality separation, a good way to increase performance is to add a reverse incline of 10-15°. The material will crawl up the discs, and its shaking time will increase by about 1.5 times. When manufacturing a separator for use in a confined space, axles are initially arranged in an arc so that the bulk of the sawdust falls through on the nearly horizontal shafts at the front, while large pieces get time to be retained, flipped several times, and fully cleaned on the last 3-4 assemblies. It is useful to add an adjustment mechanism to the holder design to select the optimal angle for any raw material.