For dosing biomass, chain and screw conveyors are the most popular in use. In both options, there is a reliable capture of the mass with separation between paddles or blades into volume-predictable clumps, and the speed of movement is quite strictly tied to the drive's rotation frequency. Belt conveyors and vibratory trays are also used for grain, pellets, and other bulk raw materials, but their setup and operation are noticeably more complex. A rotary valve doses pellets and grain well, but it can damage the product if the gap between the blades and the housing is too small, and a large gap leads to uncontrolled spilling. When working with raw sawdust, the rotary valve is extremely unstable because clumps of material stick between the blades, reducing the working volume and feed rate while maintaining constant revolutions.

Despite the simplicity of the screw design, its feed rate is not always proportional to the rotation speed. The behavior depends on the angle of installation to the horizon and the flowability of the dosed material. Here, like in a joke, there are two pieces of news - bad and good.

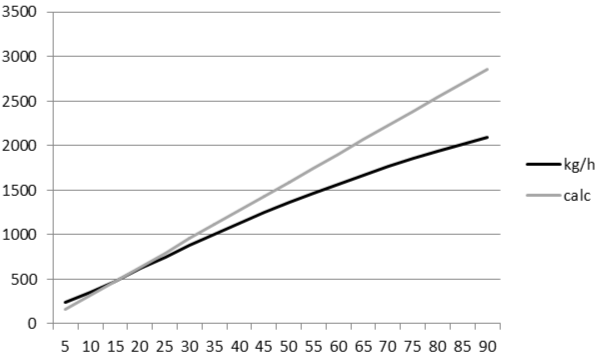

The bad news is that the differences from theoretical calculations are so substantial that they are difficult to apply in predicting the actual feed rate of the raw material. In the graph of feed rate for dry sawdust with a horizontally installed screw under a bin with a stirrer and a 150 mm (6 inches) diameter auger, two lines are depicted: the gray line represents theoretical feed rate, and the black line represents actual measured performance. At rotation speeds below 15 rpm, the actual volume exceeded the theoretical. There are two reasons for this phenomenon. First, at extremely low rotation speeds, short distance between the screw's entry and exit, and relatively large clearance between the auger and the housing, spontaneous material fallout is possible, which is especially noticeable for mineral additives or pellets when using a spiral screw. Second, very slow feeding with rhythmic stirring in the bin above the screw leads to compaction of sawdust between the screw threads and a temporary increase in bulk density, and therefore to an increase in the feed rate.

The bad news is that the differences from theoretical calculations are so substantial that they are difficult to apply in predicting the actual feed rate of the raw material. In the graph of feed rate for dry sawdust with a horizontally installed screw under a bin with a stirrer and a 150 mm (6 inches) diameter auger, two lines are depicted: the gray line represents theoretical feed rate, and the black line represents actual measured performance. At rotation speeds below 15 rpm, the actual volume exceeded the theoretical. There are two reasons for this phenomenon. First, at extremely low rotation speeds, short distance between the screw's entry and exit, and relatively large clearance between the auger and the housing, spontaneous material fallout is possible, which is especially noticeable for mineral additives or pellets when using a spiral screw. Second, very slow feeding with rhythmic stirring in the bin above the screw leads to compaction of sawdust between the screw threads and a temporary increase in bulk density, and therefore to an increase in the feed rate.

The opposite effect is observed with an inclined installation of the dosing conveyor. At too low rotations, the material slides back to the entry or moves in the desired direction several times slower than theory suggests. Clumping materials are less reactive to inclination, but mineral additives, pellets, or grain can stop entirely if the speed is insufficient.

On the right side of the graph, the difference between theory and practice reaches a 25-30% reduction in actual volume. With increasing rotation speeds, the capacity to fill the screw decreases smoothly. Moreover, data is provided for a feeder where the feed inlet stretches along the bin with a stirrer for a length of more than 1 meter (3 feet) with the possibility of filling at a wide range of rotations. However, if the feed inlet is comparable to the cross-section of the screw, then at a certain rotation speed, maximum performance is achieved and does not grow further, as the stirrer in the bin simply does not manage to collapse the arches. Thus, most of the time, the narrow entry into the screw's cavity is blocked by a clump of material.

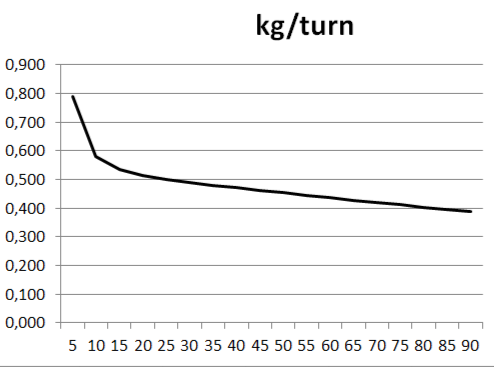

The good news is that in the middle of the operating range, the reduction coefficient of the actual feed compared to the theoretical is quite stable and correlates well for screws of different diameters and materials with varying flowability. This is noticeable in the middle part of the graph showing the amount of sawdust discharged per screw rotation depending on the rotation speed. In the range between 30 and 70 rpm, the reduction is fairly consistent. If, for continuous mixing of two or more ingredients in the flow, screws with such rotations are selected so that, with the correct proportion of components, the frequency of the supplied current to the drives differs minimally, then the frequency converters can be linked through an adjustable resistor. This way, with a change in the primary material feed rate, the screw speeds for additives will automatically adjust in the same proportion, keeping the product composition fairly stable. This allows replacing a controller, where tables of all correction coefficients across the entire speed range of feeders are programmed, with a minor complication of the connection scheme of the frequency converters.

The good news is that in the middle of the operating range, the reduction coefficient of the actual feed compared to the theoretical is quite stable and correlates well for screws of different diameters and materials with varying flowability. This is noticeable in the middle part of the graph showing the amount of sawdust discharged per screw rotation depending on the rotation speed. In the range between 30 and 70 rpm, the reduction is fairly consistent. If, for continuous mixing of two or more ingredients in the flow, screws with such rotations are selected so that, with the correct proportion of components, the frequency of the supplied current to the drives differs minimally, then the frequency converters can be linked through an adjustable resistor. This way, with a change in the primary material feed rate, the screw speeds for additives will automatically adjust in the same proportion, keeping the product composition fairly stable. This allows replacing a controller, where tables of all correction coefficients across the entire speed range of feeders are programmed, with a minor complication of the connection scheme of the frequency converters.

Metering by belt conveyor involves the free and controlled spilling of material onto the surface. The material is not restricted from above to avoid accumulation or dragging on the belt. The feed rate is measured by the height of the material layer and the belt speed. If loading onto the belt is done by a screw feeder, then the belt conveyor is equipped with load cells and serves as a control measuring device to adjust the screw's rotation speed.

Vibratory tray dosing is associated with several unpleasant issues:

- Increased dust generation

- The need for a specially trained controller to operate the solenoid vibrator when high measurement accuracy is required

- Significant inaccuracies when there is a change in moisture or flowability of the material

Therefore, vibrational dosing is rarely used in the pellet sector and only in semi-automatic pellet packaging.

Dosed feeding with a chain conveyor is successfully applied for raw wood chips, where the conveyor is the bottom part of the receiving hopper. To prevent self-discharge, a conveyor with an upper supply branch and an obligatory extension of at least 1 meter (3.3 feet) outside the hopper wall at a discharge window height of 300 mm (12 inches) is used. It is advisable to maintain this proportion for larger or smaller versions.