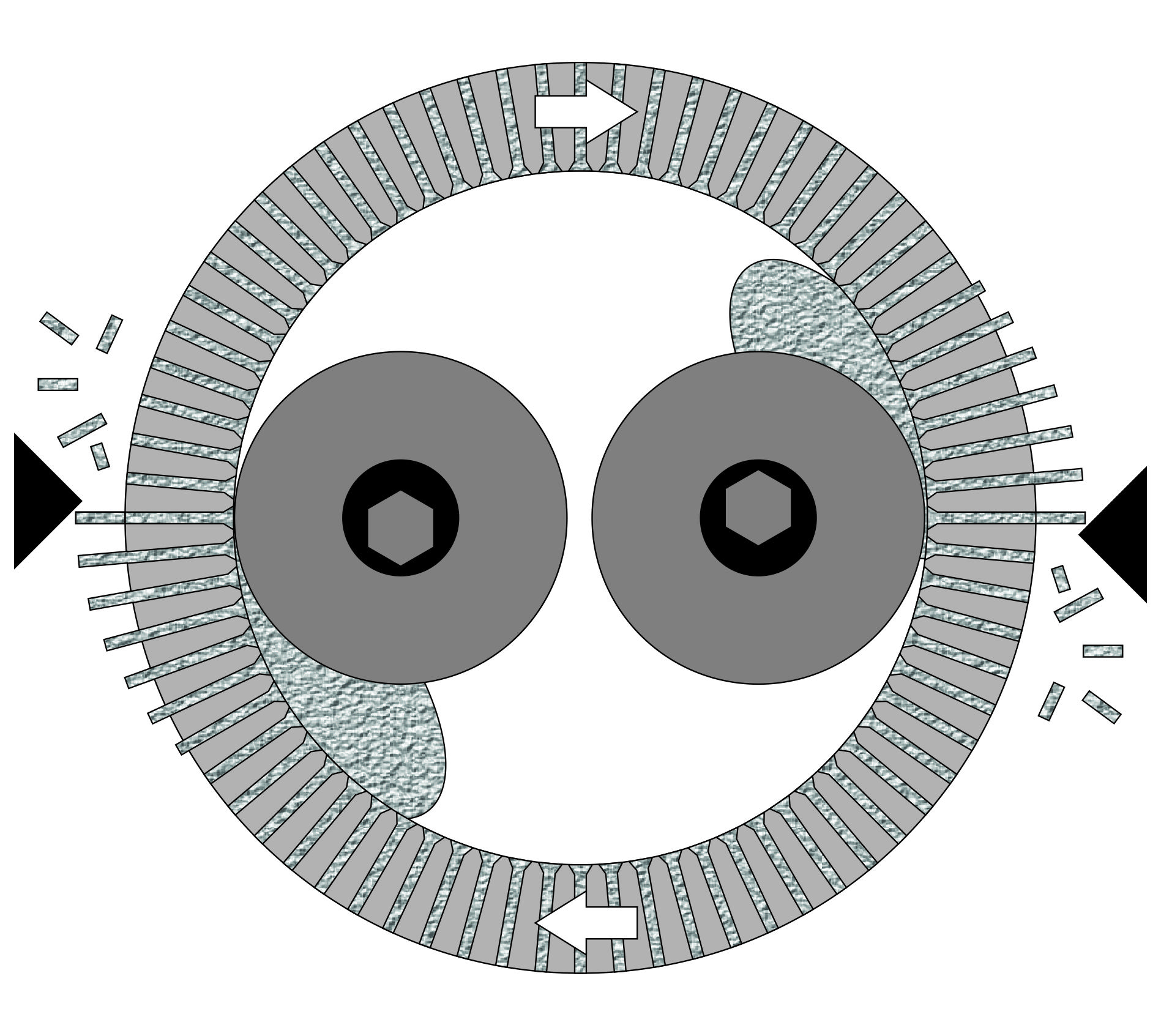

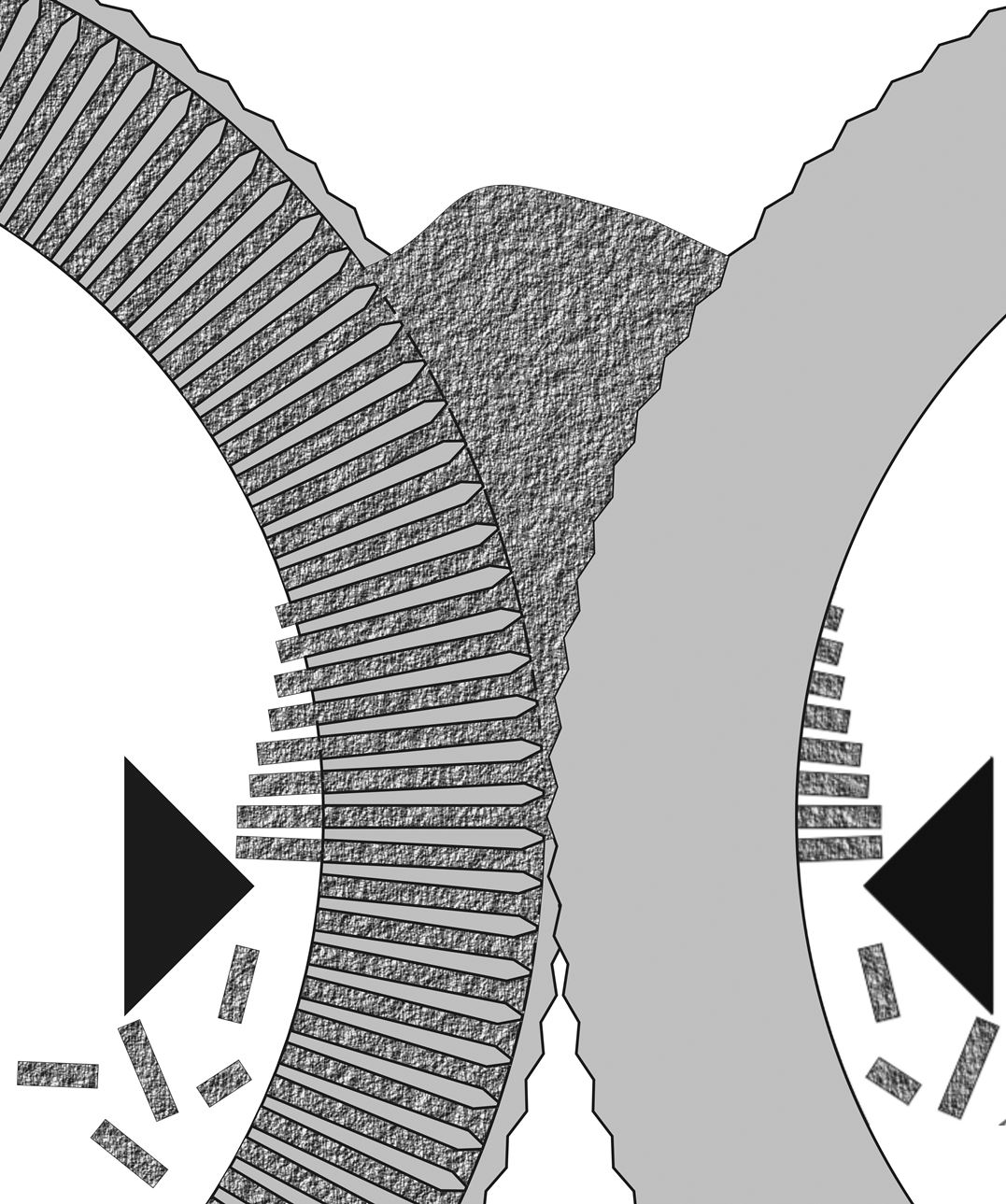

In the classic configuration of ring die pellet mills with rollers positioned inside, there are two main challenges: fitting sufficiently powerful rollers into the limited space and having the die shaft rotate externally from the stationary shaft with rollers. The double-die model eliminates these drawbacks since the bearings are placed outside the press unit. The dies are two drums, in which rows of holes alternate with ribbed projections that interlock. The projections act like a ribbed shell, compressing the material into the gaps. Inside the recesses are the die holes, forming the pellet, and the completed pellet is extruded inside the dies. This design allows for the manufacture of fairly compact, high-performance pellet mills, which are used directly in the field.

In the classic configuration of ring die pellet mills with rollers positioned inside, there are two main challenges: fitting sufficiently powerful rollers into the limited space and having the die shaft rotate externally from the stationary shaft with rollers. The double-die model eliminates these drawbacks since the bearings are placed outside the press unit. The dies are two drums, in which rows of holes alternate with ribbed projections that interlock. The projections act like a ribbed shell, compressing the material into the gaps. Inside the recesses are the die holes, forming the pellet, and the completed pellet is extruded inside the dies. This design allows for the manufacture of fairly compact, high-performance pellet mills, which are used directly in the field.

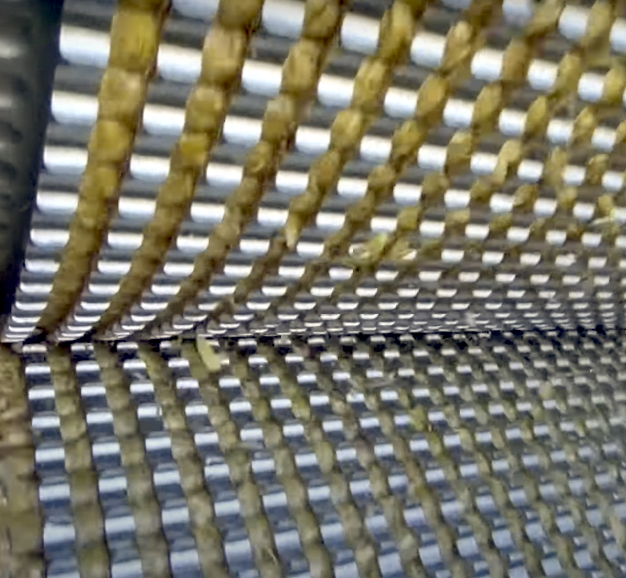

A mobile wheeled unit, besides the pellet mill, is equipped with a straw picker, which feeds straw to the pellet mill without prior shredding, provided the die holes are large enough. Typically, shredding the raw material before pelletizing serves not only to reduce the load on the pellet mill but also to facilitate feeding under the rollers. Very fluffy and fibrous material tends to clog the feeding devices of traditional pellet mills and is poorly gripped under the rollers. In the double-die pellet mill, the grip occurs over a large area, allowing air to easily escape from the particles during compression.

A mobile wheeled unit, besides the pellet mill, is equipped with a straw picker, which feeds straw to the pellet mill without prior shredding, provided the die holes are large enough. Typically, shredding the raw material before pelletizing serves not only to reduce the load on the pellet mill but also to facilitate feeding under the rollers. Very fluffy and fibrous material tends to clog the feeding devices of traditional pellet mills and is poorly gripped under the rollers. In the double-die pellet mill, the grip occurs over a large area, allowing air to easily escape from the particles during compression.

In general, external feeding of material into a ring die offers many more possibilities. If the die is left to rotate freely on its axis, and a single powered roller is pressed against it from the outside, you can create a low-power pellet mill with a large die, where the die cost can make up to 50% of the pellet mill's total cost. Moreover, a die resource of 2-3 thousand metric tons (2200-3300 US tons) for sawdust in a 22 kW (30 hp) mill with an extremely basic and easy-to-maintain design may interest developers.

In general, external feeding of material into a ring die offers many more possibilities. If the die is left to rotate freely on its axis, and a single powered roller is pressed against it from the outside, you can create a low-power pellet mill with a large die, where the die cost can make up to 50% of the pellet mill's total cost. Moreover, a die resource of 2-3 thousand metric tons (2200-3300 US tons) for sawdust in a 22 kW (30 hp) mill with an extremely basic and easy-to-maintain design may interest developers.