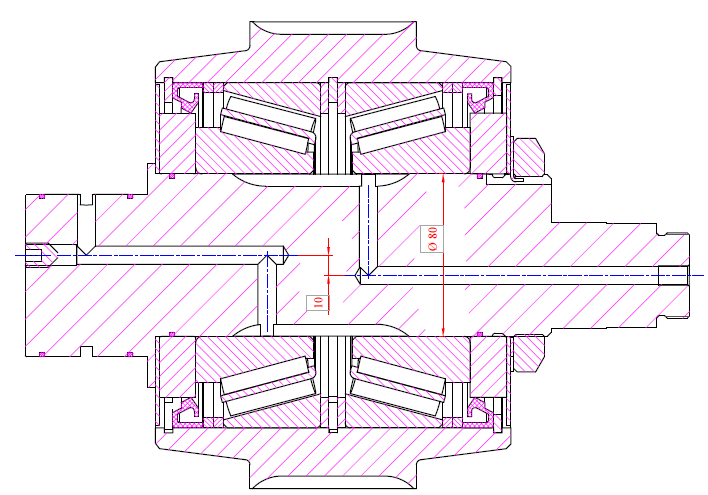

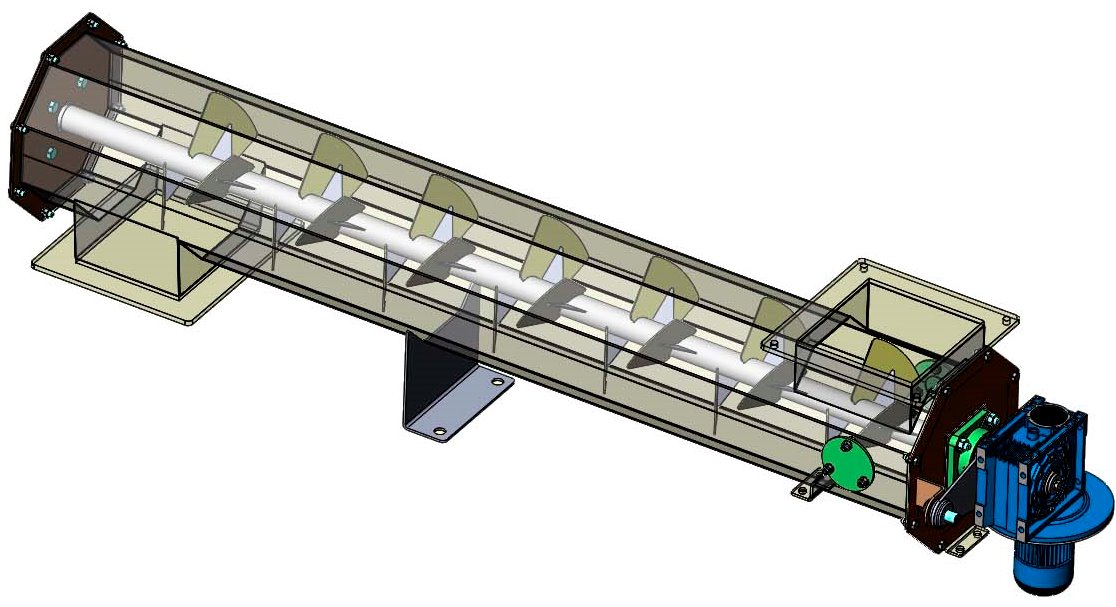

An interesting compromise was found for a drum with a capacity of 10 tons per hour. Its length is limited to 13 meters (43 feet) to fit a standard semi-trailer. The diameter of 4 meters (13 feet) exceeds the legal transport dimensions, but according to the building codes of most countries, bridges, spans, and other structures over major roads are positioned at a minimum height of 5 meters (16 feet) for such cases. Thus, using a low-bed semi-trailer, it is physically possible to transport such a drum to almost any location on the map, provided road authorities' permission is obtained. The working volume with an internal length of 12 meters (39 feet) results in 150 m³ (5,297 ft³), which corresponds to the declared capacity. The length-to-diameter ratio is 1:3, which significantly reduces bending loads and allows for "saving on metal thickness." The main feature is that only one end of the drum rests on rollers, while the other end is a solid hemisphere that transitions into a shaft supported by a large bearing assembly.

An interesting compromise was found for a drum with a capacity of 10 tons per hour. Its length is limited to 13 meters (43 feet) to fit a standard semi-trailer. The diameter of 4 meters (13 feet) exceeds the legal transport dimensions, but according to the building codes of most countries, bridges, spans, and other structures over major roads are positioned at a minimum height of 5 meters (16 feet) for such cases. Thus, using a low-bed semi-trailer, it is physically possible to transport such a drum to almost any location on the map, provided road authorities' permission is obtained. The working volume with an internal length of 12 meters (39 feet) results in 150 m³ (5,297 ft³), which corresponds to the declared capacity. The length-to-diameter ratio is 1:3, which significantly reduces bending loads and allows for "saving on metal thickness." The main feature is that only one end of the drum rests on rollers, while the other end is a solid hemisphere that transitions into a shaft supported by a large bearing assembly.

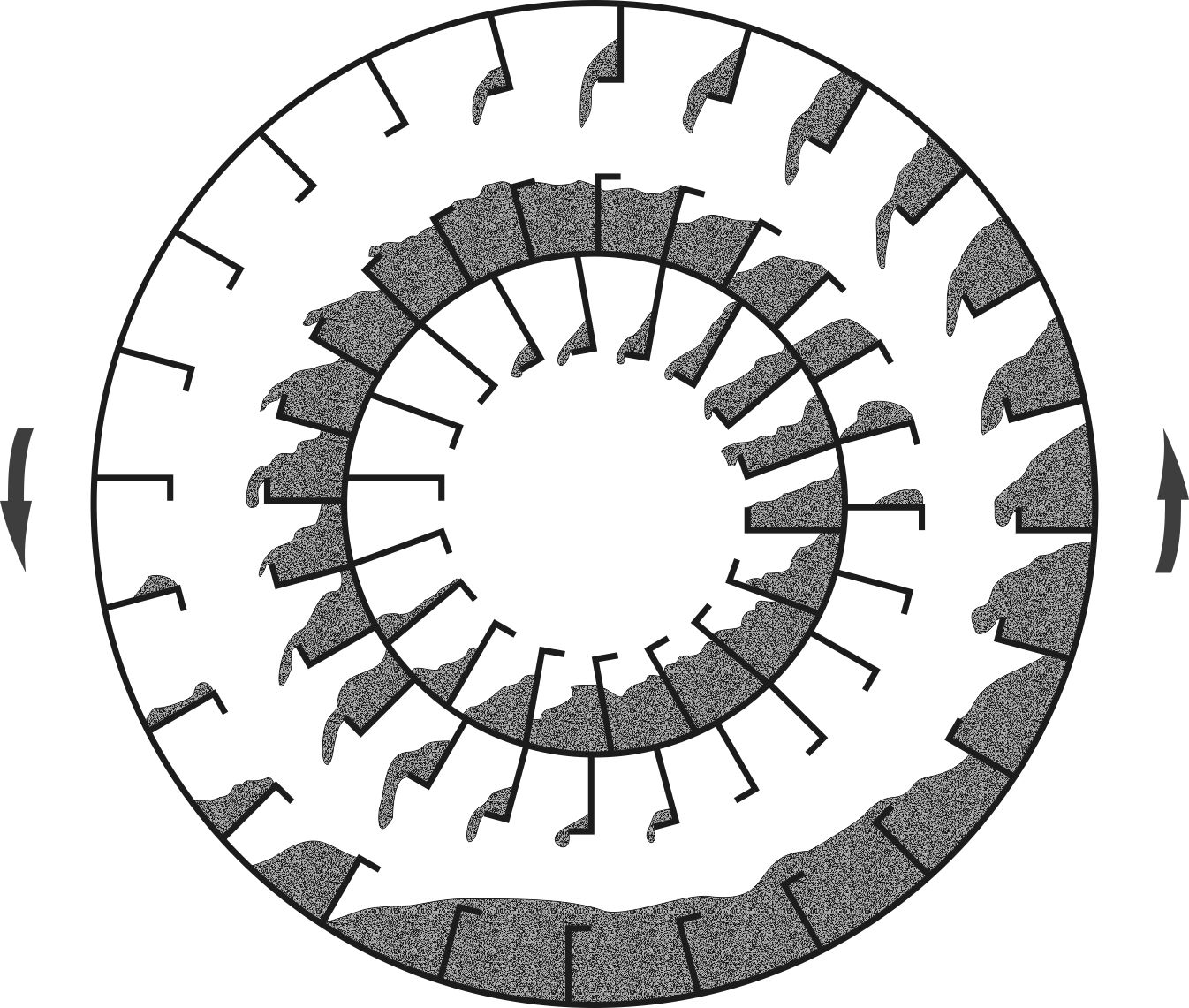

The support tire is attached internally, with a diameter of about 2.5 meters (8 feet), allowing it to be manufactured on the same carousel lathe used for smaller drums. A smaller diameter sprocket is also used but with a large enough pitch, mounted on the solid side of the drum near the bearing support.

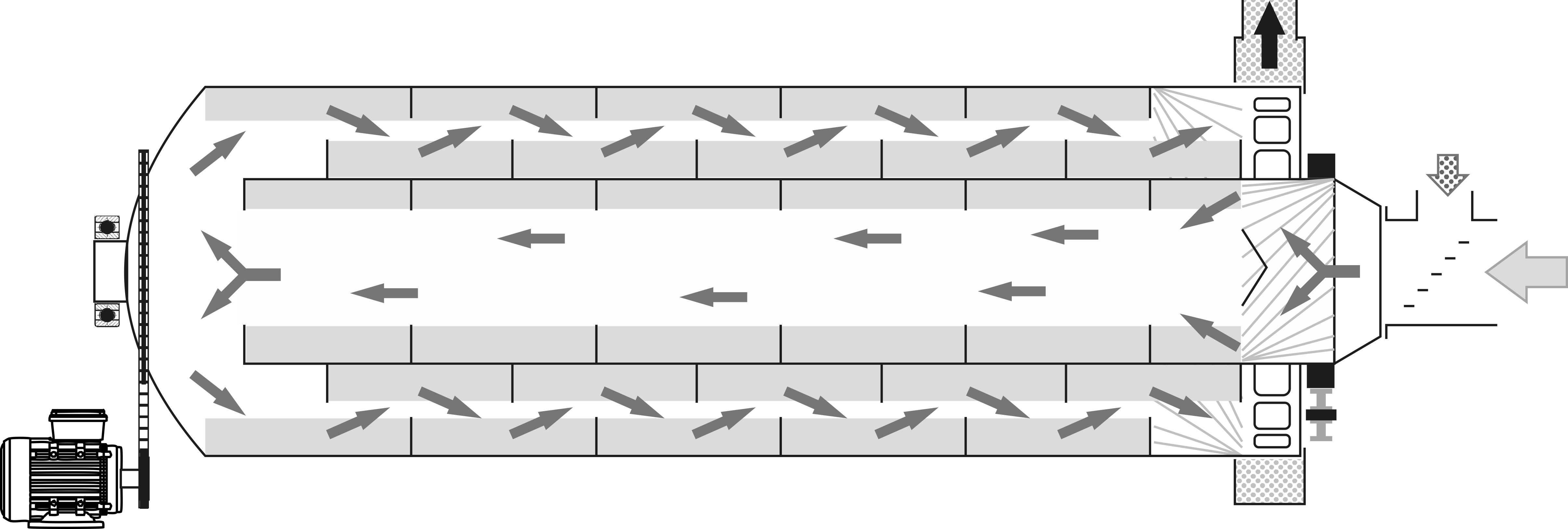

In the central part, known as the first pass, the still wet and dense material moves. Despite the wide passage and high speed of the heat agent flow, the movement of the dense material along the drum is calm, and by the time it exits to the outer contour, it has only warmed to a temperature sufficient for active moisture evaporation. As it transitions to the outer contour, the cross-sectional area increases threefold, causing the flow speed to decrease by the same factor. Here, the drying sawdust actively releases moisture as the particles are blown over and tumble between the blades. Thus, most of the raw and heavy material is closer to the bearing, which, with good lubrication and low rotation speed, is designed to last throughout the drum's life.

In the central part, known as the first pass, the still wet and dense material moves. Despite the wide passage and high speed of the heat agent flow, the movement of the dense material along the drum is calm, and by the time it exits to the outer contour, it has only warmed to a temperature sufficient for active moisture evaporation. As it transitions to the outer contour, the cross-sectional area increases threefold, causing the flow speed to decrease by the same factor. Here, the drying sawdust actively releases moisture as the particles are blown over and tumble between the blades. Thus, most of the raw and heavy material is closer to the bearing, which, with good lubrication and low rotation speed, is designed to last throughout the drum's life.

The material exits through a series of holes at the end of the drum, covered by an external casing with a sliding seal. Through this, as with ordinary drums, the dried material exits with the cooled humid heat agent.