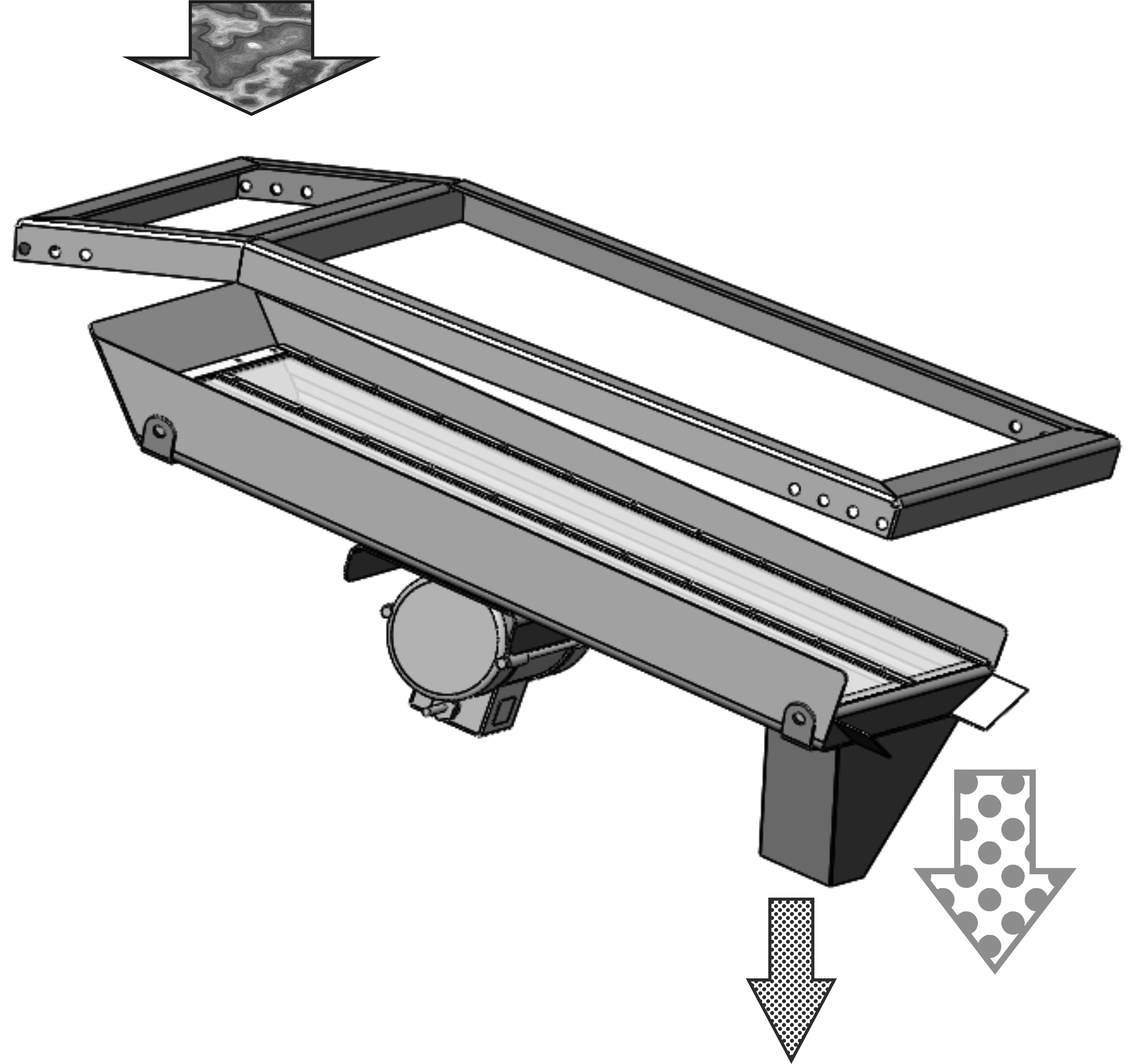

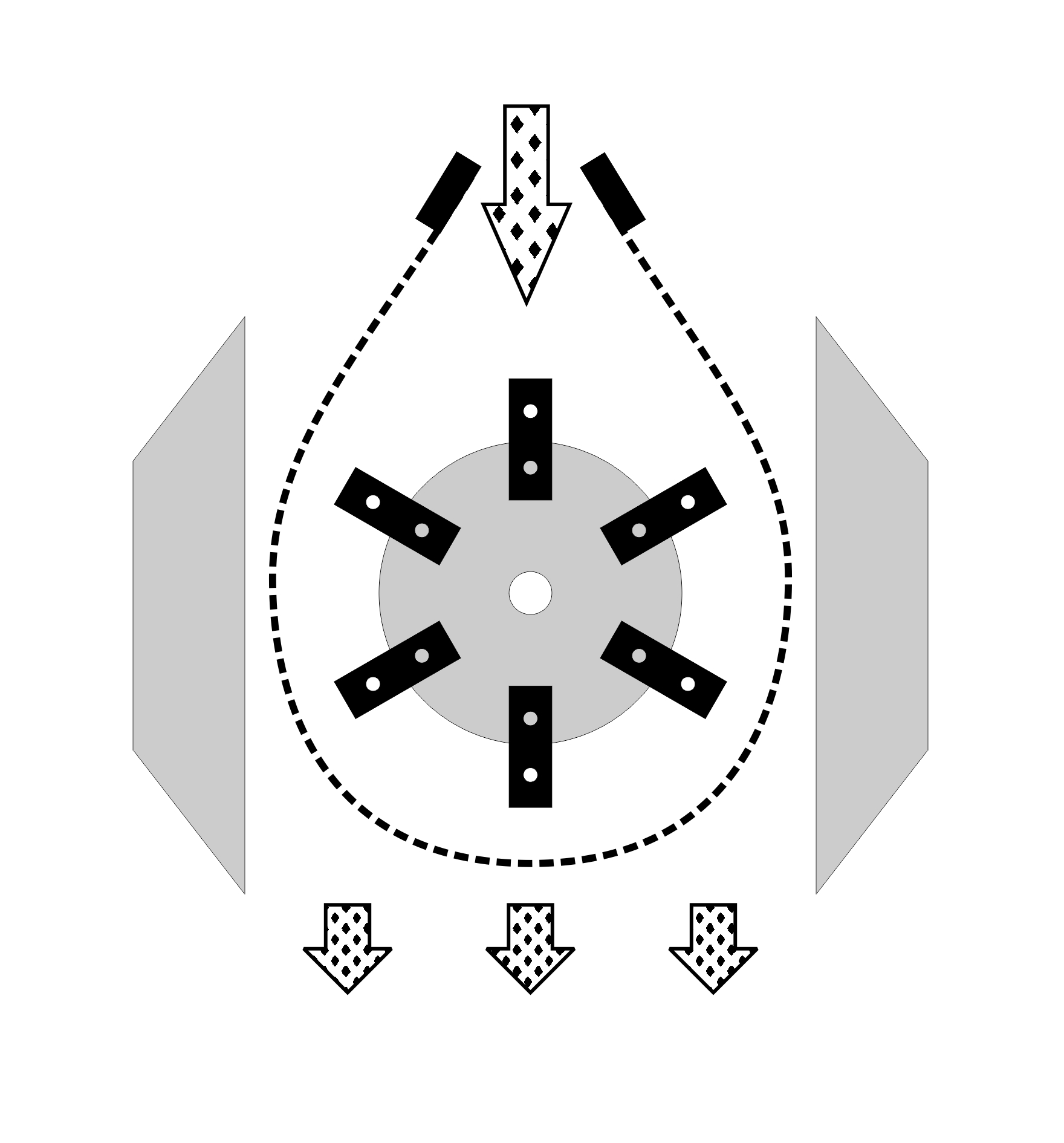

Grate hammer mills are characterized by a relatively simple design and intuitive ways to adjust the fraction size. In the most reliable units, the rotor with hammers is supported by its own bearing stand, and the crusher chamber body is protected with wear-resistant liners at points of contact with the raw material. To achieve maximum performance and efficiency, engineers aim to fill the space around the rotor with hammers with the largest possible perforated surface area. A successful design in this aspect is a teardrop-shaped hammer mill with two side screens or a single flexible screen. Material is fed from above and discharged downwards under the covers onto a conveyor or into a pneumatic transport chute. The edges of the perforated sheet wrap around the side body overhangs, while the beginning and end of the sheet are attached to a tension device above near the entrance to the crushing chamber.

Grate hammer mills are characterized by a relatively simple design and intuitive ways to adjust the fraction size. In the most reliable units, the rotor with hammers is supported by its own bearing stand, and the crusher chamber body is protected with wear-resistant liners at points of contact with the raw material. To achieve maximum performance and efficiency, engineers aim to fill the space around the rotor with hammers with the largest possible perforated surface area. A successful design in this aspect is a teardrop-shaped hammer mill with two side screens or a single flexible screen. Material is fed from above and discharged downwards under the covers onto a conveyor or into a pneumatic transport chute. The edges of the perforated sheet wrap around the side body overhangs, while the beginning and end of the sheet are attached to a tension device above near the entrance to the crushing chamber.

The most economical option is grain hammer mills, where the rotor with hammers is mounted directly on the engine shaft. The width of the perforated strip rarely exceeds 120 mm (4.7 inches), and in principle, these units can handle chipping and additional grinding of pieces in sawdust. However, a hammer mill originally designed for grain has a very small clearance between the hammer's edge and the screen, only 5-10 mm (0.2-0.4 inches), which becomes critical when using harder and more unpredictable raw materials. The entry of a large chip, knot, or trimming piece leads to an impact on the screen and almost guaranteed damage. Therefore, for processing wood raw materials, either shortened hammers are used, leaving a 20-25 mm (0.8-1 inches) gap to the screen, or two hammer mills are used in sequence, where the first uses a coarse and thick screen.

Most hammer mills with a capacity of up to 3 tons per hour have about 3000 RPM on the rotor and a hammer tip circle diameter of about 600 mm (24 inches), meaning the hammer speed is approximately 100 m/s (328 ft/s). To calculate the installed power for this setup, it is sufficient to know that for every 2 hammers with a thickness of 5 mm (0.2 inches), at least 1 kW of drive power is required. Doubling the diameter with a 1500 RPM drive theoretically maintains proportions, as the hammer speed remains the same. Note that hammer mills with an integrated fan for pneumatic transport usually require an additional 4-7 kW to move air and material. If the drive power is insufficient, the engine shuts down from overload during a brief excess of material. Excessive drive power is often used for marketing purposes, exaggerating the claimed performance relative to actual figures.

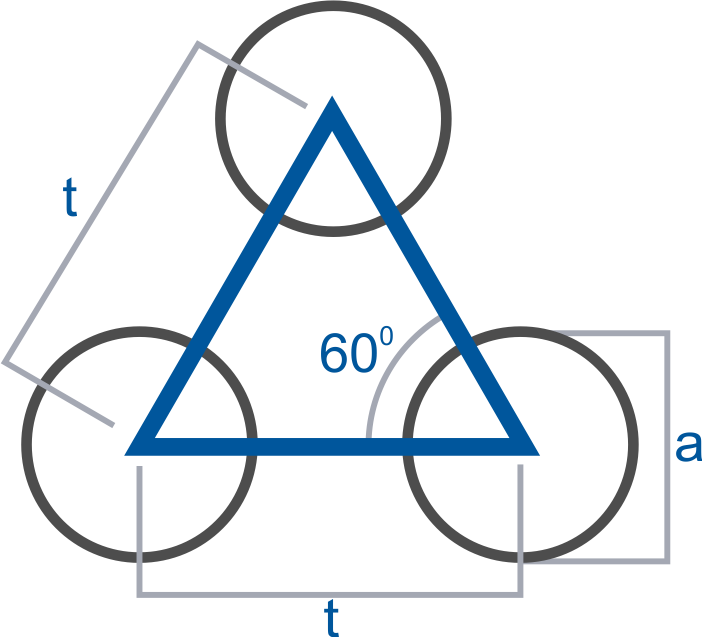

To achieve an optimal fraction size of 1-3 mm for pelletizing, screens with a 5 or 6 mm cell are typically used in hammer mills with pneumatic material extraction and 6-8 mm with mechanical extraction by various conveyors. The screen thickness is typically 3 mm (0.12 inches), with replacement needed when worn down to 1.5-2 mm (0.06-0.08 inches). For fine chip grinding, a screen with a 4 mm (0.16 inches) cell makes sense, but this size is not often popular among suppliers given the thickness. An important parameter of the perforated sheet is the perforation ratio, or the total area of openings divided by the total area of the sheet. A good ratio is 35-40%. With a lower perforation ratio, the mill's productivity significantly decreases. Greater perforation not only reduces strength but also increases the likelihood of receiving a defective sheet with damage from the punch press. It's practically impossible to order a sheet with a hole diameter equal to or less than the sheet thickness, as punch presses cannot handle it, and cutting on CNC machines using laser or waterjet is too costly.

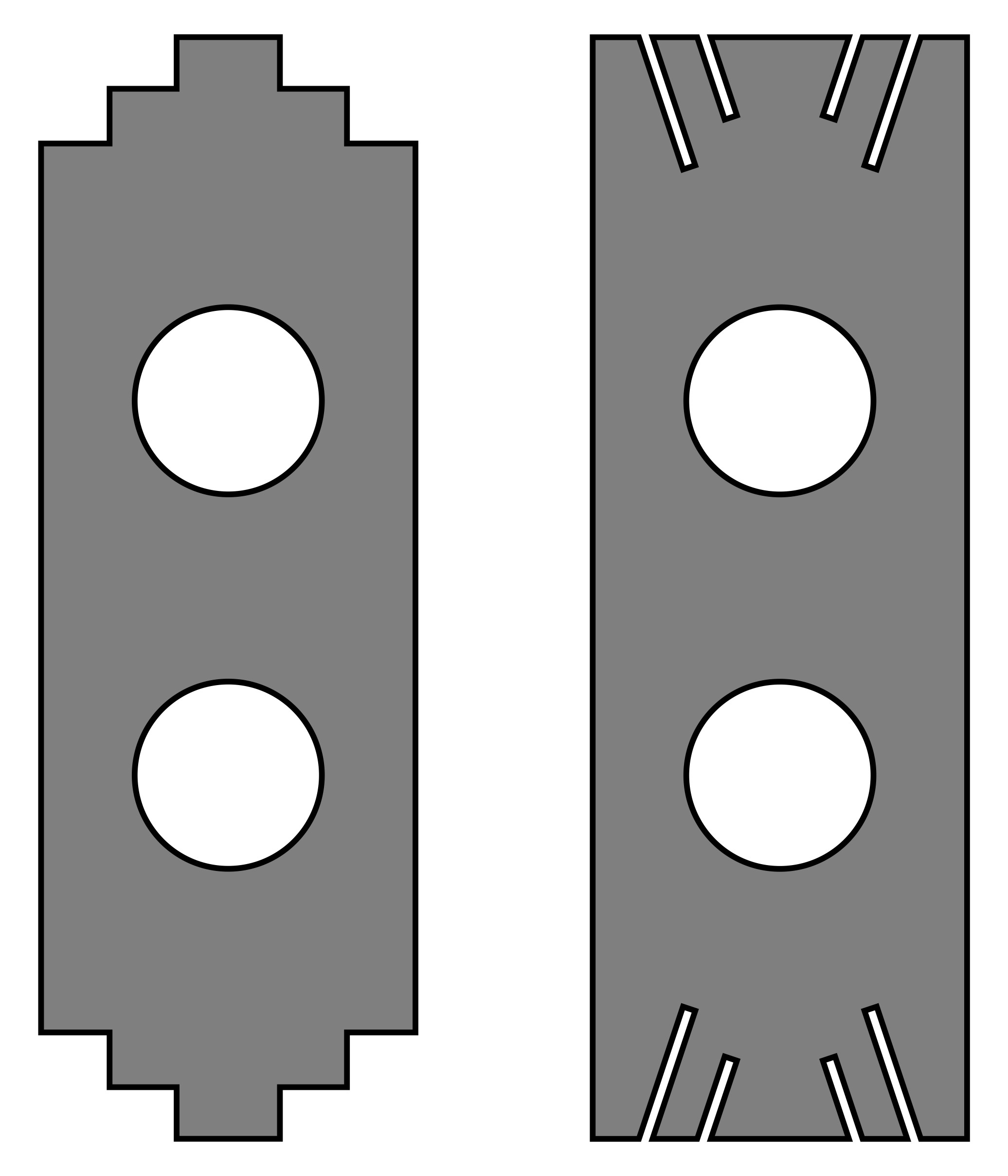

Sieves with a hexagonal arrangement of circular holes (Rv) have the highest strength and perforation ratio simultaneously, with the hole pitch t=1.5*a and the sheet thickness being 50-75% of the cell diameter. Cells in elongated shapes like rectangles or elongated ovals are often used to produce "matches" as raw material for wood concrete or composite block preforms for pallet blocks, where it's important to minimize the flour content in the material.

Sieves with a hexagonal arrangement of circular holes (Rv) have the highest strength and perforation ratio simultaneously, with the hole pitch t=1.5*a and the sheet thickness being 50-75% of the cell diameter. Cells in elongated shapes like rectangles or elongated ovals are often used to produce "matches" as raw material for wood concrete or composite block preforms for pallet blocks, where it's important to minimize the flour content in the material.

The arrangement of cells should ensure maximum throughput by reducing the speed of material movement across the sieve, meaning that hammers should not push material along blind paths between the holes. This is important to consider when cutting perforated sheets into strips suitable for the hammer mill. Usually, non-hardened sheets made of black steel are used, and fastening elements can be easily welded onto the blanks. This allows the cost of this consumable to be reduced by 3-4 times.

An exotic yet effective method is the use of expanded metal sheets with diamond-shaped cells in hammer mills with active air extraction of the material. Such a sheet is typically designated by a three-digit number where the first digit represents the thickness of the original blank, and the next two digits represent the cutting pitch in millimeters, which determines the width of the bent bridges. If the sheet is installed so that the material carried by the hammers moves "along the waves" rather than against them, the fraction separation will primarily occur by an aero-inertial method. A particle must decrease in size sufficiently to allow the airflow to turn its trajectory 180° and eject it beyond the sieve. Meanwhile, larger particles continue through inertia past the slots, colliding with the "wave" peaks of the expanded sheet. This effect becomes noticeable when the cutting pitch to sheet thickness ratio is 3:1. If the distance from the hammers to the sieve is less than 20 mm (0.8 inches), even with the use of expanded metal sheet 4x10x10 (1.5# 13R), it is possible to effectively produce wood flour of 200 microns or finer. The coarse adjustment is achieved by setting the hammer-to-sieve distance, while fine-tuning is done by adjusting the speed of the material-extracting fan. Of course, due to the imperfections in the sieve shape, hammer positioning, and other factors, along with the flour, a significant portion of larger particles will also be removed, necessitating the installation of screens for fraction separation and material recirculation for repeated grinding.

An exotic yet effective method is the use of expanded metal sheets with diamond-shaped cells in hammer mills with active air extraction of the material. Such a sheet is typically designated by a three-digit number where the first digit represents the thickness of the original blank, and the next two digits represent the cutting pitch in millimeters, which determines the width of the bent bridges. If the sheet is installed so that the material carried by the hammers moves "along the waves" rather than against them, the fraction separation will primarily occur by an aero-inertial method. A particle must decrease in size sufficiently to allow the airflow to turn its trajectory 180° and eject it beyond the sieve. Meanwhile, larger particles continue through inertia past the slots, colliding with the "wave" peaks of the expanded sheet. This effect becomes noticeable when the cutting pitch to sheet thickness ratio is 3:1. If the distance from the hammers to the sieve is less than 20 mm (0.8 inches), even with the use of expanded metal sheet 4x10x10 (1.5# 13R), it is possible to effectively produce wood flour of 200 microns or finer. The coarse adjustment is achieved by setting the hammer-to-sieve distance, while fine-tuning is done by adjusting the speed of the material-extracting fan. Of course, due to the imperfections in the sieve shape, hammer positioning, and other factors, along with the flour, a significant portion of larger particles will also be removed, necessitating the installation of screens for fraction separation and material recirculation for repeated grinding.