The full name of the apparatus is "unit for simultaneous impact-thermal drying and grinding." The principle is based on the statement that the impacts from the hammers of the hammer mill impart enough energy concentrated within a small volume of raw material at the point of contact, allowing it to instantly evaporate, exiting through the pores. Additionally, some moisture is simply "knocked out" of the raw material, like dust from a carpet. Which process prevails we leave to the scientists to debate, but what we observe in practice is the active mixing of raw material with the thermal agent at speeds close to 100 m/s (330 ft/s). This means crushing and drying occur simultaneously, and depending on the stickiness, hygroscopic nature, fibrousness, and initial fraction of the material, different products are achieved in terms of fraction and technological properties in such a dryer.

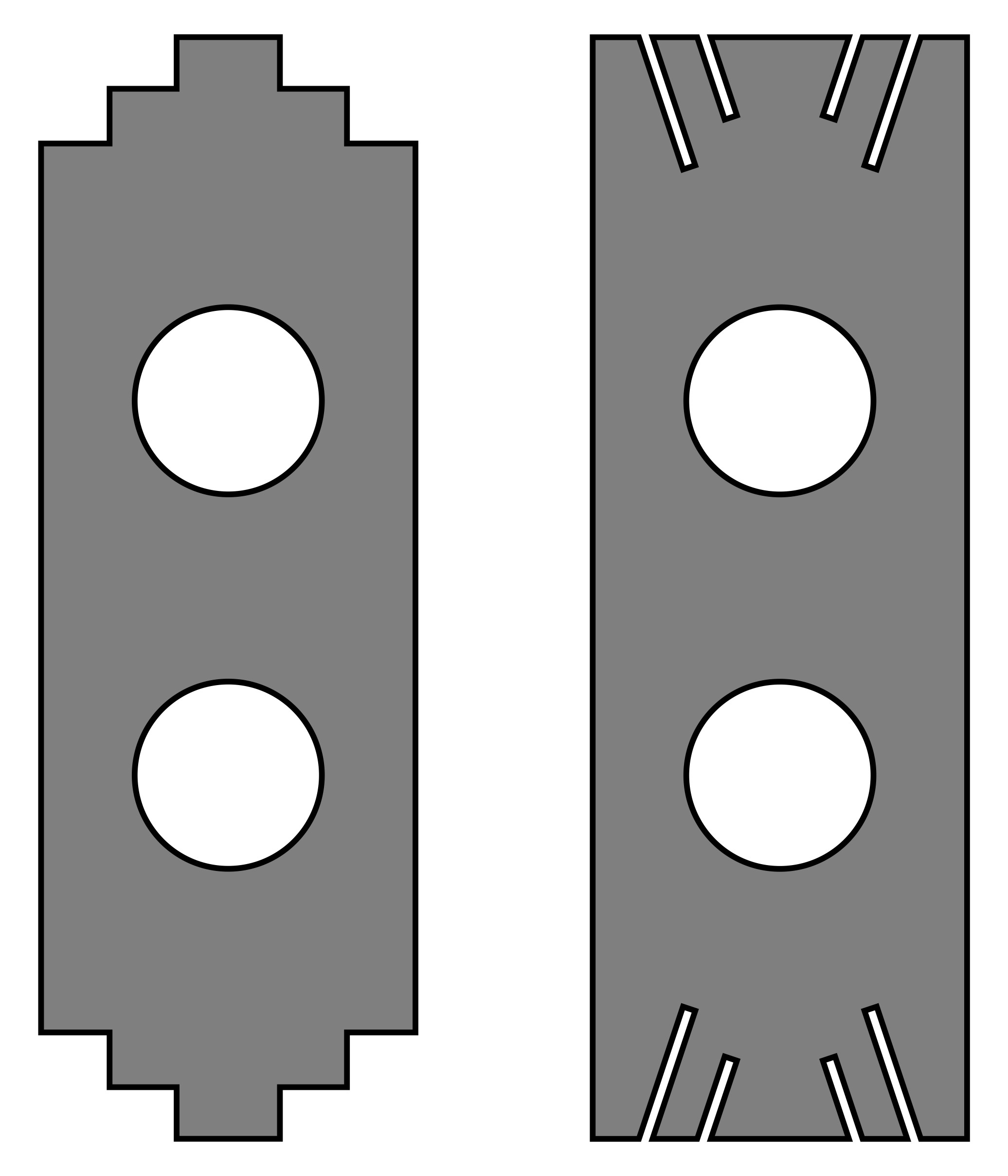

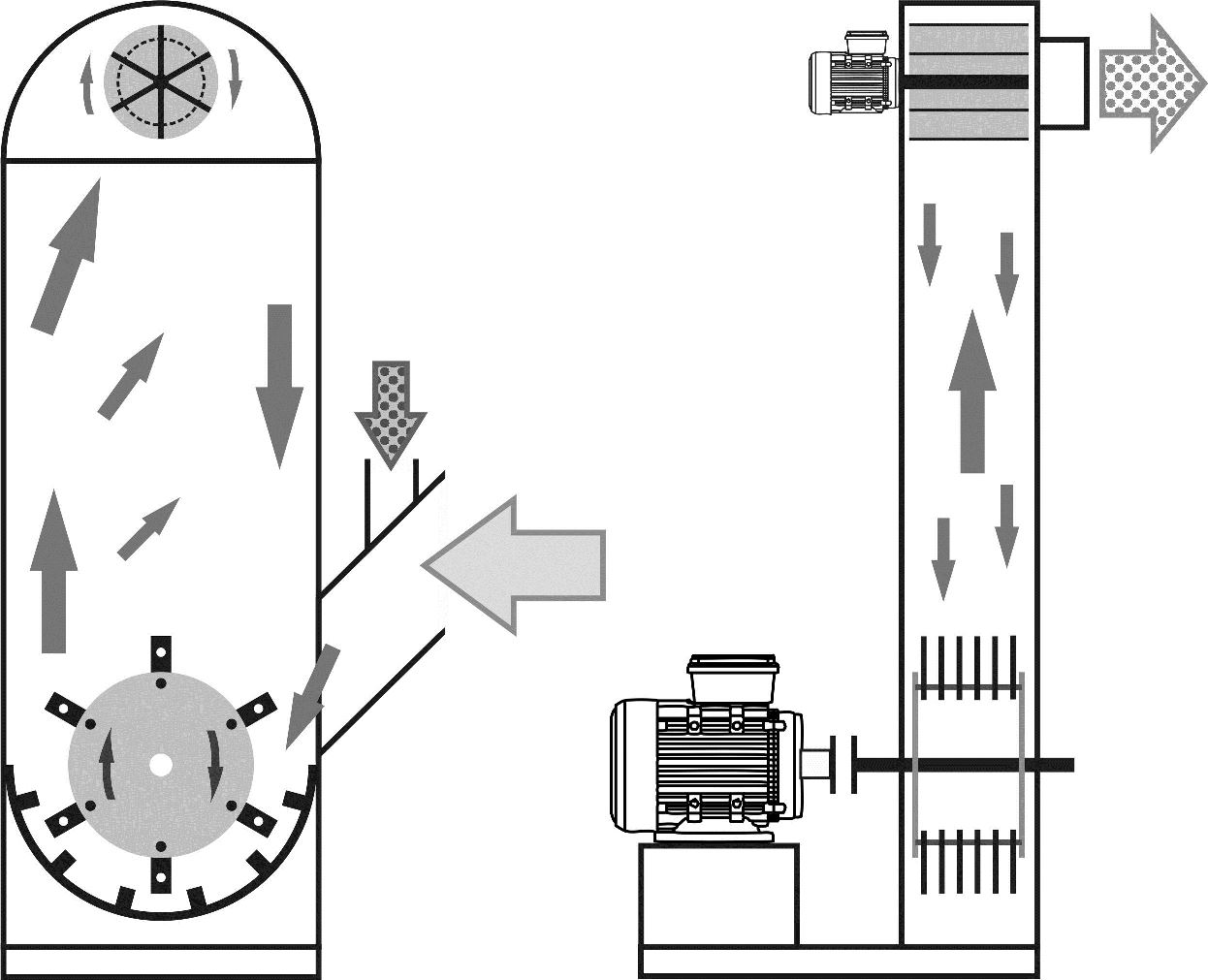

The drying and grinding unit essentially resembles the setup of a hammer mill, but with a significantly larger volume inside its casing. A classical mill combines a hammer mill and a classifier in one volume. Since drying requires much larger volumes of the thermal agent than air used for fine grinding, the input of raw material and thermal agent is conducted from the side with the assistance of descending hammers. Below the crusher rotor is a lining with counter-hammers. The number of these hammers controls the degree of grinding. The primary function of the hammers is to knock out moisture and propel the material upwards towards the classifier, which functions like a dust fan driven by a separate motor. Similar to a regular mill, larger and wetter particles are thrown back by the fan blades, while the finest and driest fractions manage to pass between them and are discharged outside. Here, the classifier acts as resistance to the draft fan.

The drying and grinding unit essentially resembles the setup of a hammer mill, but with a significantly larger volume inside its casing. A classical mill combines a hammer mill and a classifier in one volume. Since drying requires much larger volumes of the thermal agent than air used for fine grinding, the input of raw material and thermal agent is conducted from the side with the assistance of descending hammers. Below the crusher rotor is a lining with counter-hammers. The number of these hammers controls the degree of grinding. The primary function of the hammers is to knock out moisture and propel the material upwards towards the classifier, which functions like a dust fan driven by a separate motor. Similar to a regular mill, larger and wetter particles are thrown back by the fan blades, while the finest and driest fractions manage to pass between them and are discharged outside. Here, the classifier acts as resistance to the draft fan.

Separate motors are provided for the classifier and rotor, typically powered by frequency converters, allowing a wide range of adjustments. By reducing the rotor speed of the crusher, you can decrease the grinding degree and extend the drying time of the chips, yielding sawdust for pelleting rather than flour. The moisture and fraction at the output correlate and are adjusted by the classifier's speed. The space between the rotor and classifier consists of intermediate sections of the casing, and if the raw material is too moist, their number is increased, extending the flight time of the raw material and the working volume of the dryer overall.

The unit has two main advantages. Firstly, the combination of two technological processes eliminates the need for a separate crusher, multiple conveyors, and separate pneumatic transport with airlocks. This means raw material preparation occupies much less floor space compared to the classic "drum plus hammer mill" solution, and it is considerably cheaper in both procurement and installation. Secondly, despite comparable power of the main drive to that of a pellet mill, when the initial wood moisture is around 50%, the total energy consumption of the line is 10-20% less, which is a significant cost factor in low-margin waste processing.

The other declared advantages are debatable and manifest with specific technical requirements. The unit is well-suited for drying green mass with a moisture content of 80%. The leaves transition sequentially from chips to crushed particles and then to flour, with the material never becoming too sticky at any stage. However, manure with a moisture content above 70% poses challenges because clumps sticking to the walls occasionally detach and hit the rotor, creating load spikes on the drive. This triggers the emergency protection and forces a reduction in the feed rate, thus limiting productivity overall. Drying fine and very wet sawdust is also difficult because it results in wood flour fractions similar to the initial material. Without clear separation, the moisture level fluctuates too widely, making it hard for the operator to produce high-quality pellets. The very fine fraction hampers thorough heating and pellet binding, necessitating an increase in the working length of the die channel. This raises the load on the pellet mill press and logically leads to a loss in productivity.

Considering the stationary housing, it would be beneficial to organize the feeding of material separately from hot air, as is done in a rotary drum dryer with a bucket mechanism. The vacuum in the dryer is slight, so when filling the screw feeder, the likelihood of uncontrolled feeding of fairly dense raw mass is almost zero. Additionally, sticky material, when fed together with a thermal agent, behaves like large chips at the entrance to the drying drum. It dries, ignites, and discharges into the dryer. It is hard to predict how efficiently hammers will extinguish a smoldering clump in the overall mass, but the trajectory of sparking clumps in an area filled with fine dust is quite predictable.

Summarizing the above, the drying and milling unit has its market segment where it demonstrates high efficiency, cost-effectiveness, and ease of operation. Green mass, brewer’s grain, large raw chips, and decomposed manure dry well and satisfy operators. It is also quite economical to use as a mill for producing wood flour, especially if a mesh cylinder is used as a classifier, and small blades are left closer to the motor to ensure additional vacuum inside the rotating cylinder.