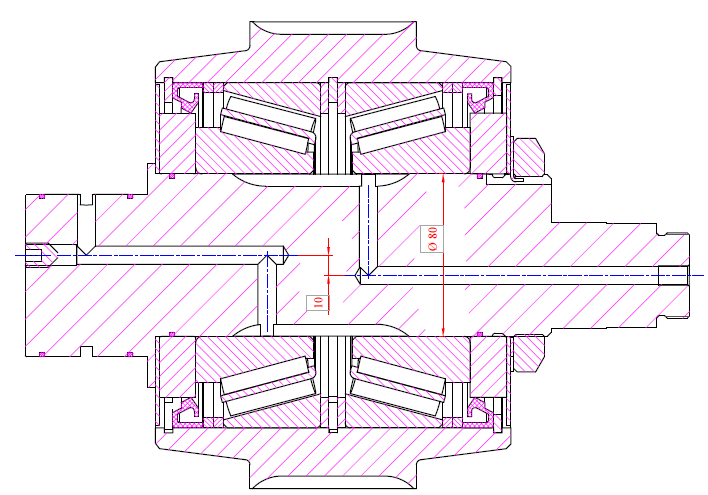

In pellet mills with ring dies, eccentric axles are commonly used in the rollers. These allow for precise and reliable adjustment of the gap between the die and the shell. The distance between the bearing axis and the rotation axis of the mounting spots in the press unit plate is also often referred to as eccentricity. This distance usually equals the thickness of the shell layer subjected to raw material abrasion, typically 7-10 mm (0.28-0.39 inches). Since similar wear on the die indicates the end of its service life, rotating the eccentric axle by 180 degrees ensures contact between the roller and die throughout the entire service life.

In some less successful pellet mill models, after the die wears by 3-5 mm (0.12-0.20 inches), installing new shells results in their side parts starting to press against the die through the material. This means the track diameter of the shell is insufficient to adequately sink into the worn die track. Often, this is accompanied by insufficient eccentricity, so even grinding the die near the track does not allow the press to start. In such cases, "repair" shells with a track diameter increased by 5 or 10 mm (0.20 or 0.39 inches) are used. This solves the problem but creates significant confusion during maintenance. Workshops accumulate shells of different sizes with varying degrees of wear, turning maintenance into a juggling act with bearings and shells instead of stable operation with significant production volumes.

In some less successful pellet mill models, after the die wears by 3-5 mm (0.12-0.20 inches), installing new shells results in their side parts starting to press against the die through the material. This means the track diameter of the shell is insufficient to adequately sink into the worn die track. Often, this is accompanied by insufficient eccentricity, so even grinding the die near the track does not allow the press to start. In such cases, "repair" shells with a track diameter increased by 5 or 10 mm (0.20 or 0.39 inches) are used. This solves the problem but creates significant confusion during maintenance. Workshops accumulate shells of different sizes with varying degrees of wear, turning maintenance into a juggling act with bearings and shells instead of stable operation with significant production volumes.