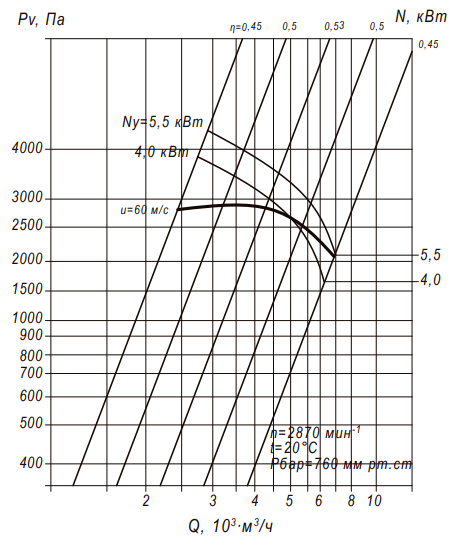

For relatively simple pneumatic transport systems with a total tract length of up to 20 meters (65 feet), typical dust fans like the VCP 7-40 are used. They have a few blades arranged strictly in a radial direction, which allows dust that accumulates to constantly fall off the blades, achieving self-cleaning. Most of these fans can create a vacuum of 2500 Pa (0.36 psi), which is sufficient to overcome the combined resistance of the ducts with bends and a cyclone. It's usually best to operate fans close to their maximum pressure where the efficiency exceeds 50%. As shown in the VCP 7-40 №4 graph, this range is between 3500 and 5500 m³/h (2060 and 3240 cfm). From the graph, we can also determine that the actual power consumption of the motor will be between 2.5 and 4 kW (3.4 to 5.4 hp). The maximum load on the fan motor occurs at minimal duct resistance when the fan moves the maximum possible mass of air, which for this model is 7000 m³/h (4120 cfm) at 5.5 kW (7.4 hp).

For relatively simple pneumatic transport systems with a total tract length of up to 20 meters (65 feet), typical dust fans like the VCP 7-40 are used. They have a few blades arranged strictly in a radial direction, which allows dust that accumulates to constantly fall off the blades, achieving self-cleaning. Most of these fans can create a vacuum of 2500 Pa (0.36 psi), which is sufficient to overcome the combined resistance of the ducts with bends and a cyclone. It's usually best to operate fans close to their maximum pressure where the efficiency exceeds 50%. As shown in the VCP 7-40 №4 graph, this range is between 3500 and 5500 m³/h (2060 and 3240 cfm). From the graph, we can also determine that the actual power consumption of the motor will be between 2.5 and 4 kW (3.4 to 5.4 hp). The maximum load on the fan motor occurs at minimal duct resistance when the fan moves the maximum possible mass of air, which for this model is 7000 m³/h (4120 cfm) at 5.5 kW (7.4 hp).

Manufacturers often offer fans with the same geometry and speed specifications but with different motor power to save energy. In practice, most industrial motors with more than 50% load already achieve an efficiency of over 90%, meaning that once they are more than half-loaded, their energy consumption is proportional to the load and there is no overspending. Fans with deliberately weak motors should not be started without being connected to the duct system or with a fully open inlet, as this can overload the motor and overheat the windings. Given the extremely uneven operation of pneumatic transport, it's better to install a more powerful motor and focus on other aspects.

Manufacturers often offer fans with the same geometry and speed specifications but with different motor power to save energy. In practice, most industrial motors with more than 50% load already achieve an efficiency of over 90%, meaning that once they are more than half-loaded, their energy consumption is proportional to the load and there is no overspending. Fans with deliberately weak motors should not be started without being connected to the duct system or with a fully open inlet, as this can overload the motor and overheat the windings. Given the extremely uneven operation of pneumatic transport, it's better to install a more powerful motor and focus on other aspects.

When the pneumatic transport system operates under vacuum, wood chips move relatively steadily at an air concentration of up to 500 g/m³ (0.031 lb/ft³). For the described model, this translates to an average of up to 2 tonnes per hour (2.2 tons/hr). The resistance of bends and the cyclone increases proportionally with the material content relative to the mass of air. If the material is passed through the fan to operate the system under pressure, a proportional increase in motor power is needed along with the use of thicker wear-resistant blades.

There are so-called "product" fans which differ from dust fans by having thicker blades and producing 2-3 times more pressure. These fans are often mounted on the end of a crusher on the same shaft as its rotor. They create a pressure of about 5-6 kPa (0.73-0.87 psi) and for moving 2-3 tonnes per hour (2.2-3.3 tons/hr), they take about 7-8 kW (9.4-10.7 hp) from the crusher's drive while moving 2500-3000 m³/h (1472-1766 cfm) of air. This configuration significantly reduces overall equipment cost but turns the blades into consumables for the crusher.

When stable material transfer over long distances is required, involving high resistance in the straight section and throughout the system, using medium or high-pressure fans in systems operating under pressure makes sense. Since these fans are equipped with inclined blades that are prone to getting clogged with dust, they are placed before material is introduced into the ductwork. It's advisable to remember the "acceleration section" of 5-8 duct diameters from the fan to where the material meets the air stream, ensuring the flow effectively captures the particles.

When stable material transfer over long distances is required, involving high resistance in the straight section and throughout the system, using medium or high-pressure fans in systems operating under pressure makes sense. Since these fans are equipped with inclined blades that are prone to getting clogged with dust, they are placed before material is introduced into the ductwork. It's advisable to remember the "acceleration section" of 5-8 duct diameters from the fan to where the material meets the air stream, ensuring the flow effectively captures the particles.