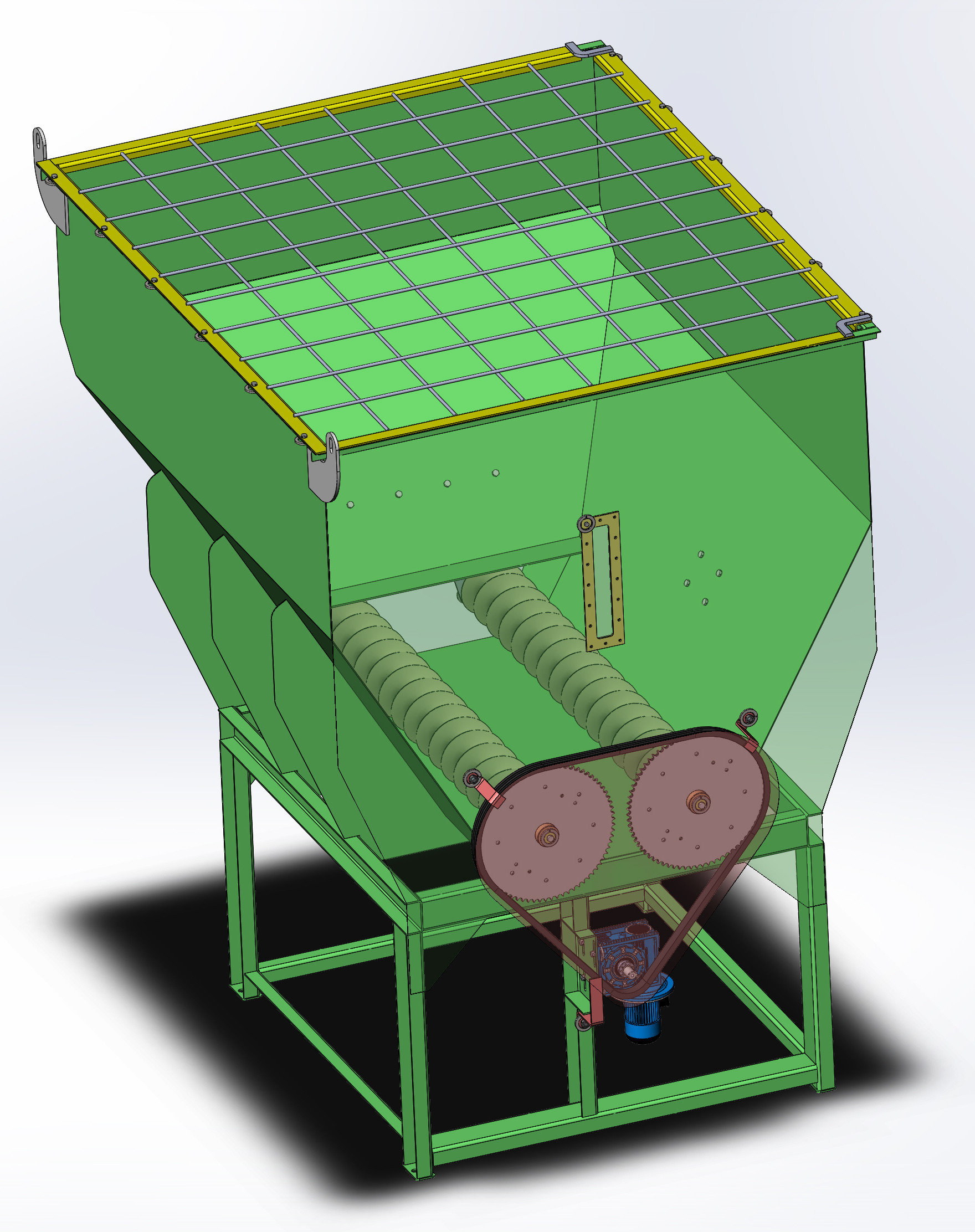

The fastest way to organize a uniform and reliable supply of bulk raw materials with a wide range of productivity adjustments is to use ready-made feed dispensers, detached from their chassis. A gear motor with a power of about 2-4 kW and an output of 30-60 RPM is installed in place of the power take-off shaft, providing sufficient functionality for use in pelletizing lines with up to 3 tons per hour of finished product. This solution has five advantages:

The fastest way to organize a uniform and reliable supply of bulk raw materials with a wide range of productivity adjustments is to use ready-made feed dispensers, detached from their chassis. A gear motor with a power of about 2-4 kW and an output of 30-60 RPM is installed in place of the power take-off shaft, providing sufficient functionality for use in pelletizing lines with up to 3 tons per hour of finished product. This solution has five advantages:

- The ready-made design is quite cheap when mass-produced, and chains, sprockets, and bearings are as accessible as car parts.

- The feed rate, in addition to the initially rough regulation by mechanical means, is complemented by the possibility of fine-tuning using a frequency converter, allowing for relatively simple integration with the general control system.

- The absence of hydraulics and the initially outdoor design allows for disregard of climatic conditions during use.

- The presence of initially provided agitators to break up clumps of compacted raw materials.

- The presence of a built-in cross conveyor, under which a crusher or other unit can be compactly placed.

Of course, agitators are also installed at the outlet of hydraulic stokers, but there it is a separate drive with its own complication in coordinating with hydraulics. In the feed dispenser, however, all rotational frequency ratios have been refined over decades and work with a wide variety of raw materials, from cattle manure to freshly cut grass. The vertical walls practically eliminate arching, and the entire mass moves continuously.

When ordering such a design, attention should be paid to the manufacturer's consideration of the body's strength, given that loading of raw materials may be carried out using a front loader. It is also much simpler and cheaper to order additional sides that stack onto the standard ones on three sides, leaving one free for the bucket. This extra structure is very useful for light materials like shavings or dry sawdust. It will only need to be covered to protect from precipitation and provided with a curtain.

The use of an anchor-type chain for scrapers at the bottom of the feed dispenser is highly undesirable, as the sprockets for such a chain easily get clogged with freezing wet fibers. A bushing or roller chain with additional seals in the links is suitable if the raw material is so wet that it leaves a wet trace on the hands. For chips, sawdust, and other wastes with moisture content up to 55%, a standard conveyor chain with pre-installed bolt mounts on every fourth or eighth link is quite suitable. In Russia, the TRD-38-3000 is most popular for these purposes, where 38 is the distance between roller centers in millimeters, and 3000 is the breaking load limit in Newtons. With a feed dispenser width of 2 meters (7 feet), 4 chains are sufficient. The maximum body length for materials with a bulk density up to 400 kg/m³ (25 lb/ft³) is 6 meters (20 feet). A longer length is not advisable as increasing the number of chains sharply increases the load on the drive shaft, and enlarging its diameter would require a drive replacement with 7-10 times the torque and leads to an unreasonable increase in unit cost. Thus, this design is optimal only for working volumes from 10 to 25 cubic meters (2,600 to 6,600 gallons) and is well-suited for direct supply of raw materials to drying complexes and crushers.

The use of an anchor-type chain for scrapers at the bottom of the feed dispenser is highly undesirable, as the sprockets for such a chain easily get clogged with freezing wet fibers. A bushing or roller chain with additional seals in the links is suitable if the raw material is so wet that it leaves a wet trace on the hands. For chips, sawdust, and other wastes with moisture content up to 55%, a standard conveyor chain with pre-installed bolt mounts on every fourth or eighth link is quite suitable. In Russia, the TRD-38-3000 is most popular for these purposes, where 38 is the distance between roller centers in millimeters, and 3000 is the breaking load limit in Newtons. With a feed dispenser width of 2 meters (7 feet), 4 chains are sufficient. The maximum body length for materials with a bulk density up to 400 kg/m³ (25 lb/ft³) is 6 meters (20 feet). A longer length is not advisable as increasing the number of chains sharply increases the load on the drive shaft, and enlarging its diameter would require a drive replacement with 7-10 times the torque and leads to an unreasonable increase in unit cost. Thus, this design is optimal only for working volumes from 10 to 25 cubic meters (2,600 to 6,600 gallons) and is well-suited for direct supply of raw materials to drying complexes and crushers.

To reduce the load on the chains in these hoppers, specially shaped scrapers are used. They either have a triangular cross-section or are stamped into an M-shaped profile. Scrapers are attached to the chains in such a manner that the resistance from the raw material helps press the scraper against the base, along which it slides. If installed backward, the scrapers tend to surface the pile, causing the chain to arch upward and are likely to break due to excessive tension. The sharpened edges of the scrapers not only cut more easily into the bulk of the material but also help to scrape off any clumps that freeze to the bottom.

To reduce the load on the chains in these hoppers, specially shaped scrapers are used. They either have a triangular cross-section or are stamped into an M-shaped profile. Scrapers are attached to the chains in such a manner that the resistance from the raw material helps press the scraper against the base, along which it slides. If installed backward, the scrapers tend to surface the pile, causing the chain to arch upward and are likely to break due to excessive tension. The sharpened edges of the scrapers not only cut more easily into the bulk of the material but also help to scrape off any clumps that freeze to the bottom.

It is crucial to leave a sufficient gap between the scrapers and the edges of the outlet window for the raw material, calculated as at least three times the maximum average fraction size. Otherwise, the chain movement will regularly stop, and if the hopper feeds a dryer, this can provoke a fire hazard situation.

When feeding material with a front loader or conveyor from a great height, installing a grid with a 200x200 mm (8x8 inch) cell instead of the hopper lid can be useful. This holds back large debris, sticks, and similar impurities, which can lead to stoppage or damage to equipment. It is a mistake to install such a grid deep in the hopper to reduce the load on the dispenser, as this leads to constant material hang-ups.

Often, for cost-saving at maximum volume, rectangular hoppers with a tapered bottom are attempted, to which a chain conveyor is also attached. They work quite stably with large chips or mineral raw materials with high flowability. However, with fibrous materials and sawdust, problems with arching often arise, which cannot be overcome with additional vibrators. For challenging materials, the opposite approach is taken by creating negative wall angles to prevent self-compaction of the mass under its own weight.