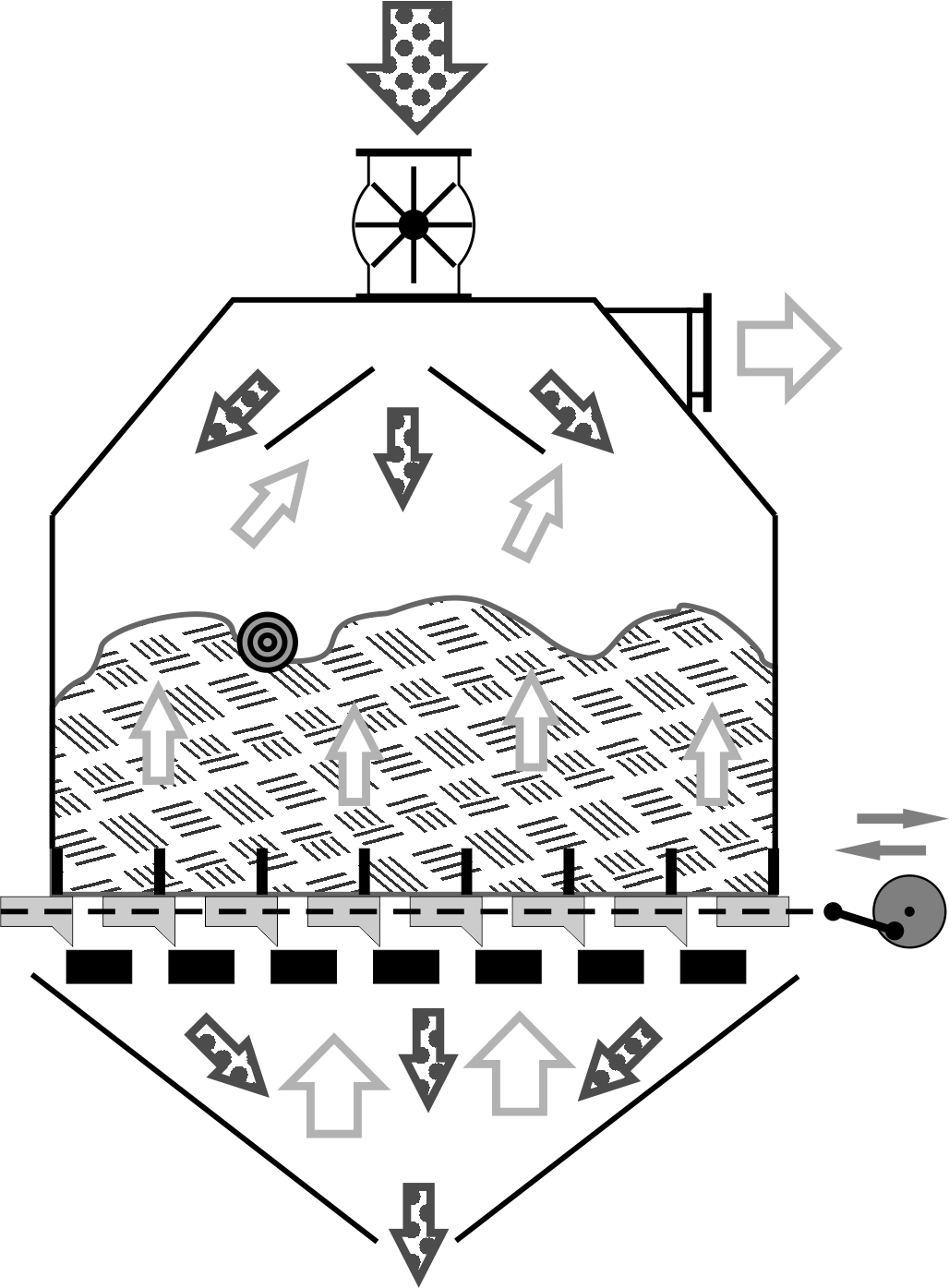

For capacities up to 5 tonnes per hour, the sifter is positioned directly beneath the cooler, and a unified aspiration system is used to collect the fines fraction. Typically, only 1/10th of the total airflow is needed for pneumatic transport, which is why the duct from the sifter to the main duct is 3 times smaller in diameter than the duct from the cooler cavity. With a pellet bed thickness of 0.25 meters (10 inches) and airflow of 2000 cubic meters (528,000 gallons) of air per tonne, sufficient vacuum is created for the slot ejector of the sifter, as described in the section on pneumatic transport.

For capacities up to 5 tonnes per hour, the sifter is positioned directly beneath the cooler, and a unified aspiration system is used to collect the fines fraction. Typically, only 1/10th of the total airflow is needed for pneumatic transport, which is why the duct from the sifter to the main duct is 3 times smaller in diameter than the duct from the cooler cavity. With a pellet bed thickness of 0.25 meters (10 inches) and airflow of 2000 cubic meters (528,000 gallons) of air per tonne, sufficient vacuum is created for the slot ejector of the sifter, as described in the section on pneumatic transport.

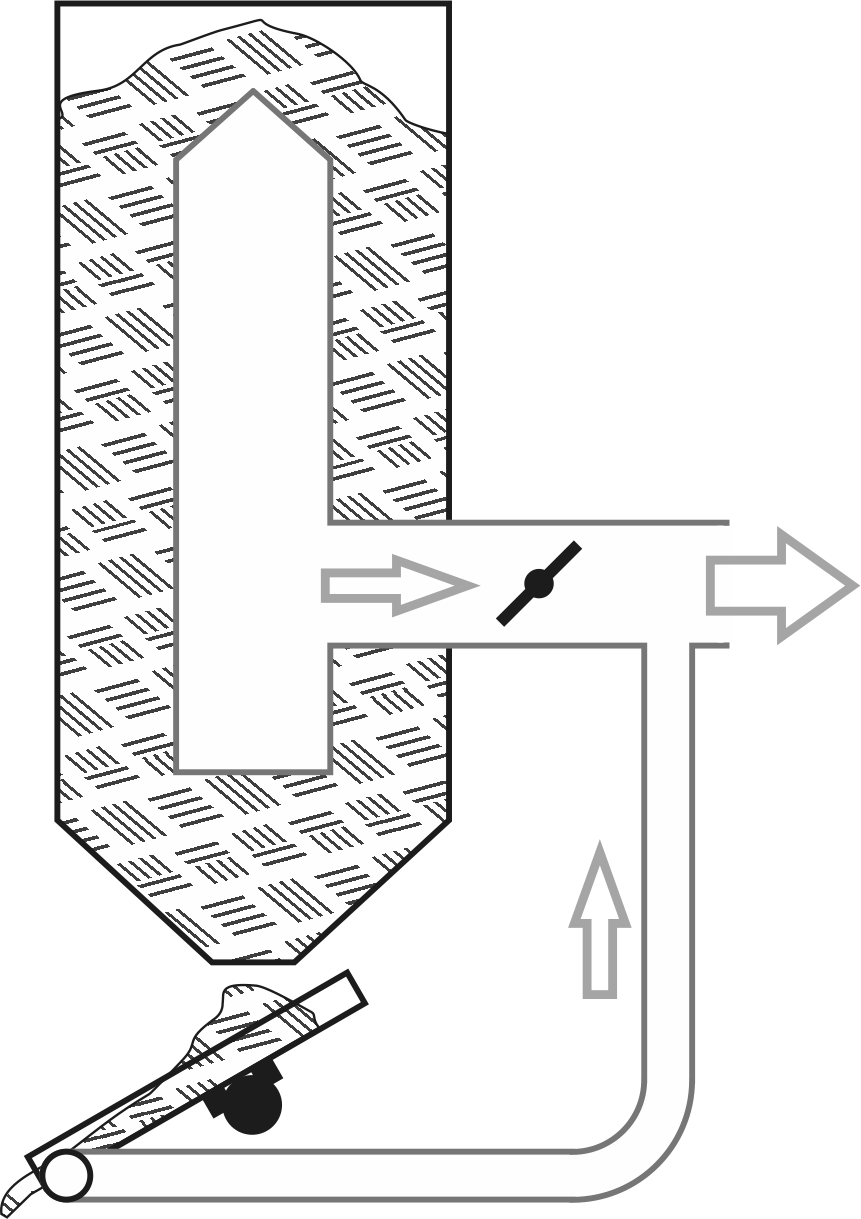

Connecting the sifter to the common aspiration system of the cooler greatly simplifies and reduces assembly costs but has one drawback. When the cooler needs to be completely emptied of pellets, the sifting quality decreases. Exposing the internal part of the louvered cooler or reducing the counterflow cooler layer leads to a sharp drop in vacuum in the duct, and the fines stop being removed from under the sifter. Essentially, the screening ceases to function, and some pellets become unsuitable for sale. This problem is solved quite simply: a throttle valve is installed between the cooler's outlet and the sifter's pipe connection, blocking airflow and creating additional resistance. This restores vacuum in the slot ejector and ensures effective fines separation. The valve should be partially closed at an angle of 45-60°, with the exact position determined visually by observing the removal of separated dust. Complete closure is not recommended as it leaves air with only one path through the sifter, reducing speed in large pipes by 3-5 times, leading to fines accumulation in vertical sections with possible complete blockage. The adjusted position of the throttle valve should be marked on the lever to quickly set the correct angle for unloading in the future.

This valve can also be useful when switching to larger pellets, as layer resistance decreases and it becomes necessary to increase vacuum for pneumatic transport in adjacent ducts. The flexibility of the dust fan offsets these losses, and overall, the throttle does not affect the efficiency of the cooler.