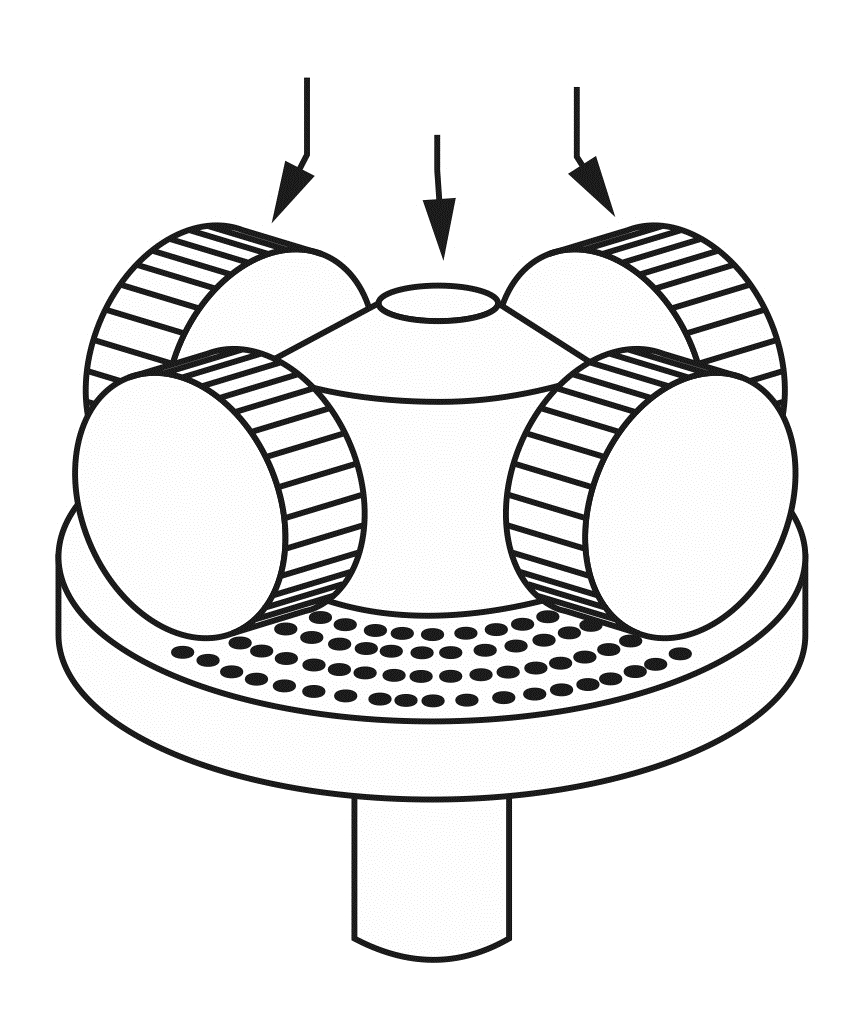

A fixed flat die is installed directly into the pellet mill housing, and rollers, typically numbering from 2 to 4, roll over it from above. Such a die is fairly simple and inexpensive to manufacture, so the specific costs for it are noticeably lower than for pellet mills with a ring die. Another advantage of the design is the straightforward feeding and distribution of raw material, which, upon reaching the center, is immediately distributed by the rollers and forced into the die holes. Since the load on the rollers is not counterbalanced by each other, all the load is directed onto the shaft, which pulls the assembly down onto the die. The shaft head must be adapted for mounting multiple rollers, and the mounting location primarily experiences a cantilever load. In some models, the rollers are cone-shaped, positioning the roller axes at an angle to the die. This reduces excessive friction between the rollers and the die but adds complexity to the configuration. Thus, the moving shaft with rollers becomes a very complex part requiring high-quality milling and hardening. With relatively high reliability, such units usually have the highest initial price, which can deter investors. On the other hand, numerous examples of successful operation of such German pellet mills with a capacity of 4 to 5 metric tons (4.4 to 5.5 US tons) per hour on wood sawdust show significant savings due to low operating costs with proper and timely maintenance.

A fixed flat die is installed directly into the pellet mill housing, and rollers, typically numbering from 2 to 4, roll over it from above. Such a die is fairly simple and inexpensive to manufacture, so the specific costs for it are noticeably lower than for pellet mills with a ring die. Another advantage of the design is the straightforward feeding and distribution of raw material, which, upon reaching the center, is immediately distributed by the rollers and forced into the die holes. Since the load on the rollers is not counterbalanced by each other, all the load is directed onto the shaft, which pulls the assembly down onto the die. The shaft head must be adapted for mounting multiple rollers, and the mounting location primarily experiences a cantilever load. In some models, the rollers are cone-shaped, positioning the roller axes at an angle to the die. This reduces excessive friction between the rollers and the die but adds complexity to the configuration. Thus, the moving shaft with rollers becomes a very complex part requiring high-quality milling and hardening. With relatively high reliability, such units usually have the highest initial price, which can deter investors. On the other hand, numerous examples of successful operation of such German pellet mills with a capacity of 4 to 5 metric tons (4.4 to 5.5 US tons) per hour on wood sawdust show significant savings due to low operating costs with proper and timely maintenance.

The pressing of the rollers against the die is accomplished hydraulically based on the same principle as an automobile's power steering. A spool mechanism sets the required position and clearance, and the hydraulic force strives to maintain these settings. The hydraulic system also provides protection. When metal objects enter or during overload conditions, the hydraulics allow the rollers to move away from the die, reducing the load on the main drive and stopping based on sensor signals.

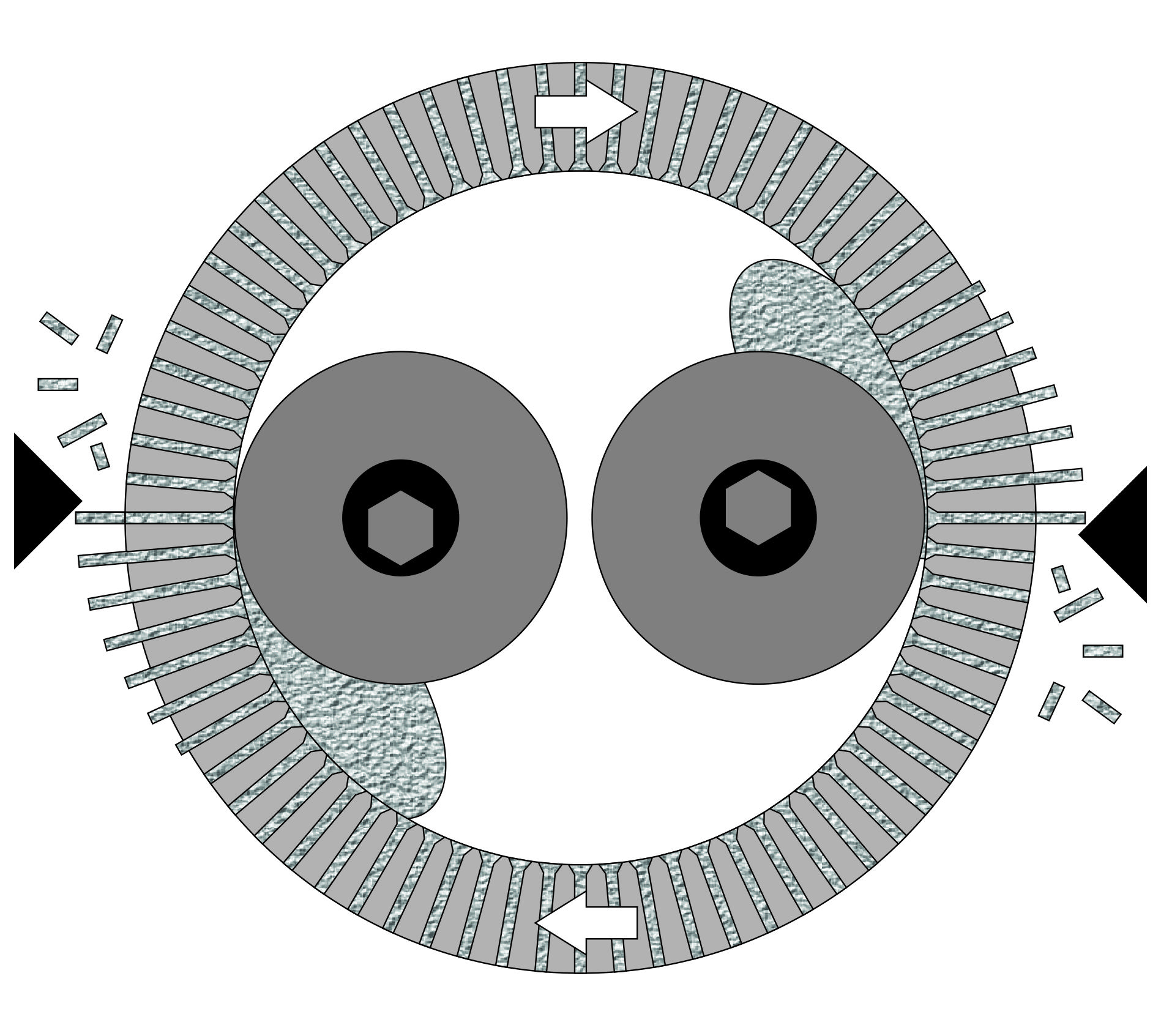

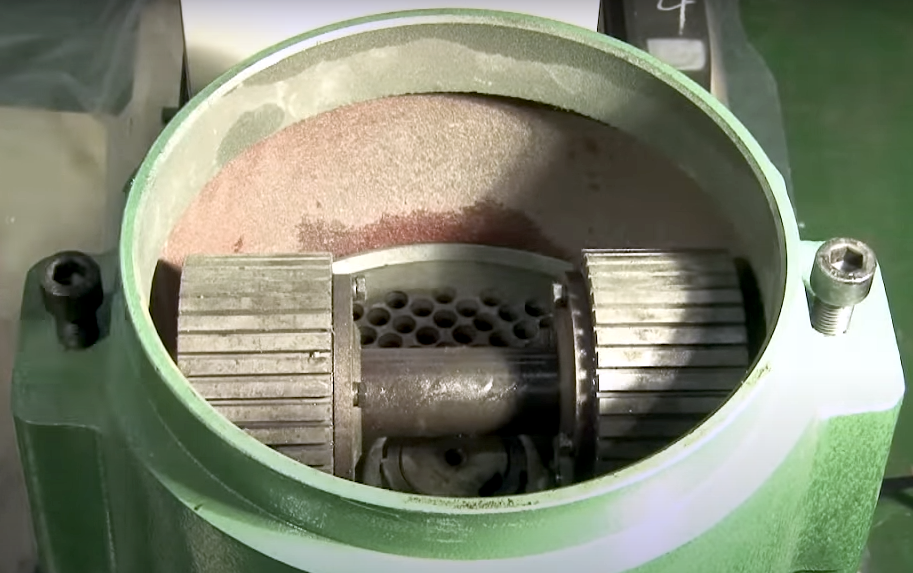

There are many small semi-domestic pellet mills with a similar working principle. For simplicity, they use only two rollers, and the pressing adjustment to the die is done with a central nut. Tightening the nut shifts the axis of the rollers downward, sliding along the shaft and key.

There are many small semi-domestic pellet mills with a similar working principle. For simplicity, they use only two rollers, and the pressing adjustment to the die is done with a central nut. Tightening the nut shifts the axis of the rollers downward, sliding along the shaft and key.

Despite the relatively low reliability of such models for pelletizing wood, the principle of material distribution allows high productivity when processing animal feed and green grass. Even visually, it is noticeable that the track width of the rollers is too large for the bearings contained within. And, while in larger pellet mills of this type, lubrication is continuously supplied during operation, here regular stopping is necessary, and excessive grease does not expel dirt from the seals, leading to known consequences.