There are simplified models of pellet mills where the ring die is stationary, and the rollers rotate. For instance, Swedish pellet mills are designed in such a way that a vertical die is mounted to the gearbox casing, and the rollers rotate inside it. Despite the presence of paddles and various adjustments, more raw material is inevitably fed to the lower part of the die than to the upper part. As a result, the die needs to be rotated 180° after processing every 100 to 200 metric tons (110 to 220 US tons) of raw material to ensure even wear along the entire circumference of the track.

Chinese manufacturers have relatively successfully addressed this drawback of the fixed ring die by placing it horizontally and reducing the track width. This ensures a more even distribution of raw material across the sectors of the die, but the lower rows of the die holes still receive much more material than the upper rows during partial press loading. To ensure even wear, it's necessary to adjust the feed, observing the difference in pellet extrusion speed from the die rows, and maintain productivity within narrow limits. Using a massive die with a narrow track increased the cost of consumables, which led to another original solution. They made two tracks on the die with symmetrical mounts, allowing the die to be flipped and the tracks to be used alternately. The difficulty in organizing lubrication for moving rollers and a stationary die remains a challenge, although with modern capabilities, this is successfully addressed at a relatively low cost for components. The biggest disadvantage of this design is the lack of a protective device, and the entry of large metal objects into the sawdust can lead to sudden failure of expensive shafts or even the gearbox.

Chinese manufacturers have relatively successfully addressed this drawback of the fixed ring die by placing it horizontally and reducing the track width. This ensures a more even distribution of raw material across the sectors of the die, but the lower rows of the die holes still receive much more material than the upper rows during partial press loading. To ensure even wear, it's necessary to adjust the feed, observing the difference in pellet extrusion speed from the die rows, and maintain productivity within narrow limits. Using a massive die with a narrow track increased the cost of consumables, which led to another original solution. They made two tracks on the die with symmetrical mounts, allowing the die to be flipped and the tracks to be used alternately. The difficulty in organizing lubrication for moving rollers and a stationary die remains a challenge, although with modern capabilities, this is successfully addressed at a relatively low cost for components. The biggest disadvantage of this design is the lack of a protective device, and the entry of large metal objects into the sawdust can lead to sudden failure of expensive shafts or even the gearbox.

The negative aspects of the design are offset by some advantages, of which the most significant is the price. This is the cheapest pellet mill with a gear drive and a ring die. This was achieved in several ways:

- The use of a standard industrial gearbox manufactured in series.

- Excluding the coupling between the motor and the gearbox, simply using a flange connection of the casings. The result is a regular large motor-gearbox combination. The largest popular pellet mill has a drive power of 250 kW (335 hp).

- The stationary die is mounted on a relatively inexpensive cast housing installed on top of the gearbox. Thus, the gearbox casing serves as the supporting structure, eliminating the need for a frame and reducing the amount of bent parts and the length of welds by dozens of meters.

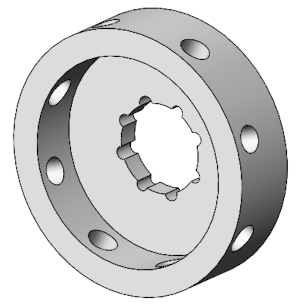

- The die mounting itself consists of small earrings with a curved arc-shaped profile matching the die, and a wedge-shaped cross-section. With their small size and low cost, wedging in the seating with gripping the edge of the die provides secure attachment. This engineering solution is much more justified than clamping the die and flange from the outside with a single ring or segment clamps that work under tension and, as a result, have much greater mass and cost.

- A fairly massive die with a narrow track does not require an additional reinforcing ring on the top side, and the cost of reinforcement can account for up to 50% of the die's price.

- Top feeding eliminates the need for a feeding device, which not only reduces the machine's cost but also lowers the number of components requiring maintenance.

- The roller shaft is mounted on three powerful bearings: two tapered and one spherical roller bearing. This removes the radial load from the gearbox shaft, ensuring smoother conditions and a solid operating time before failure.