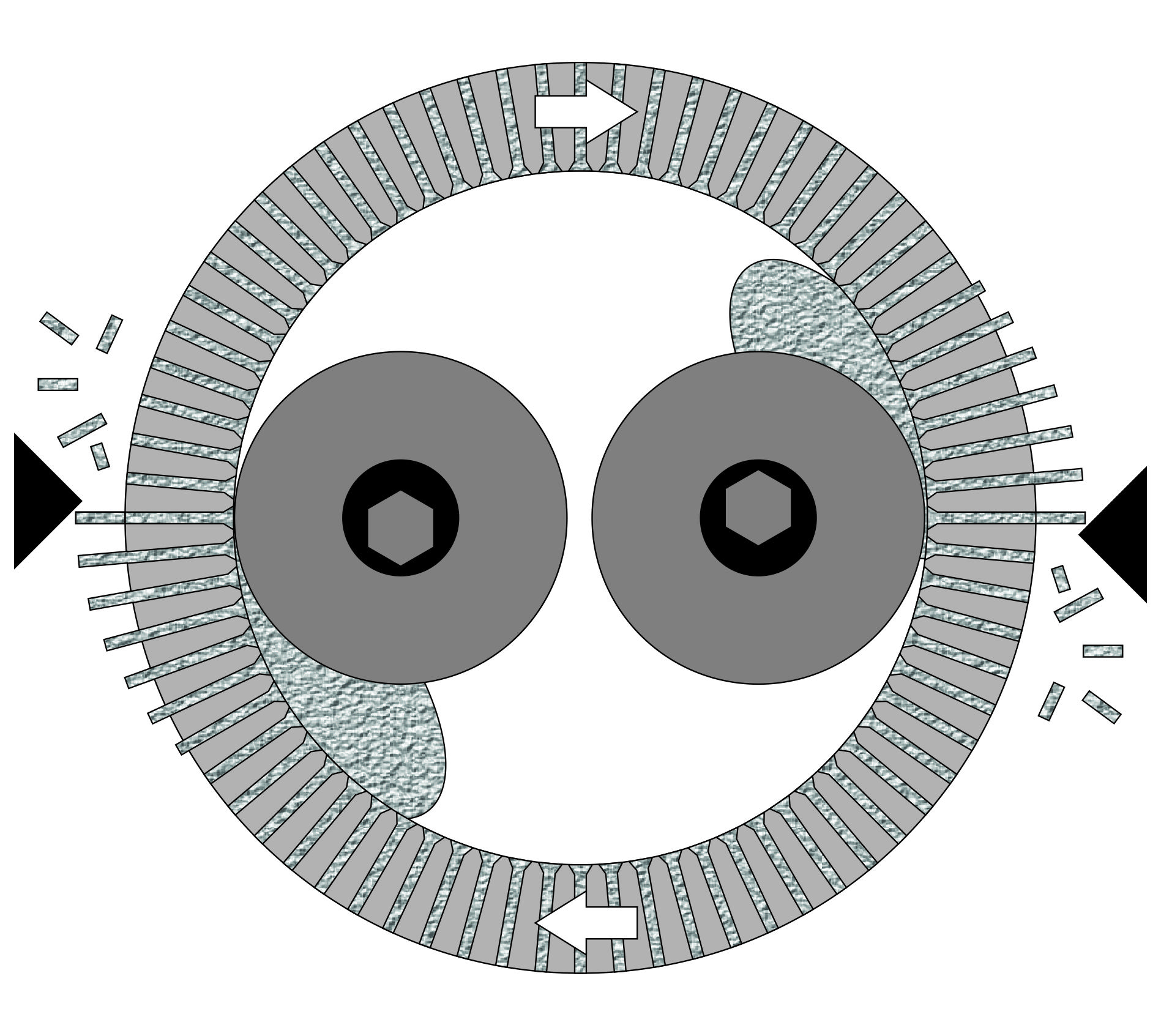

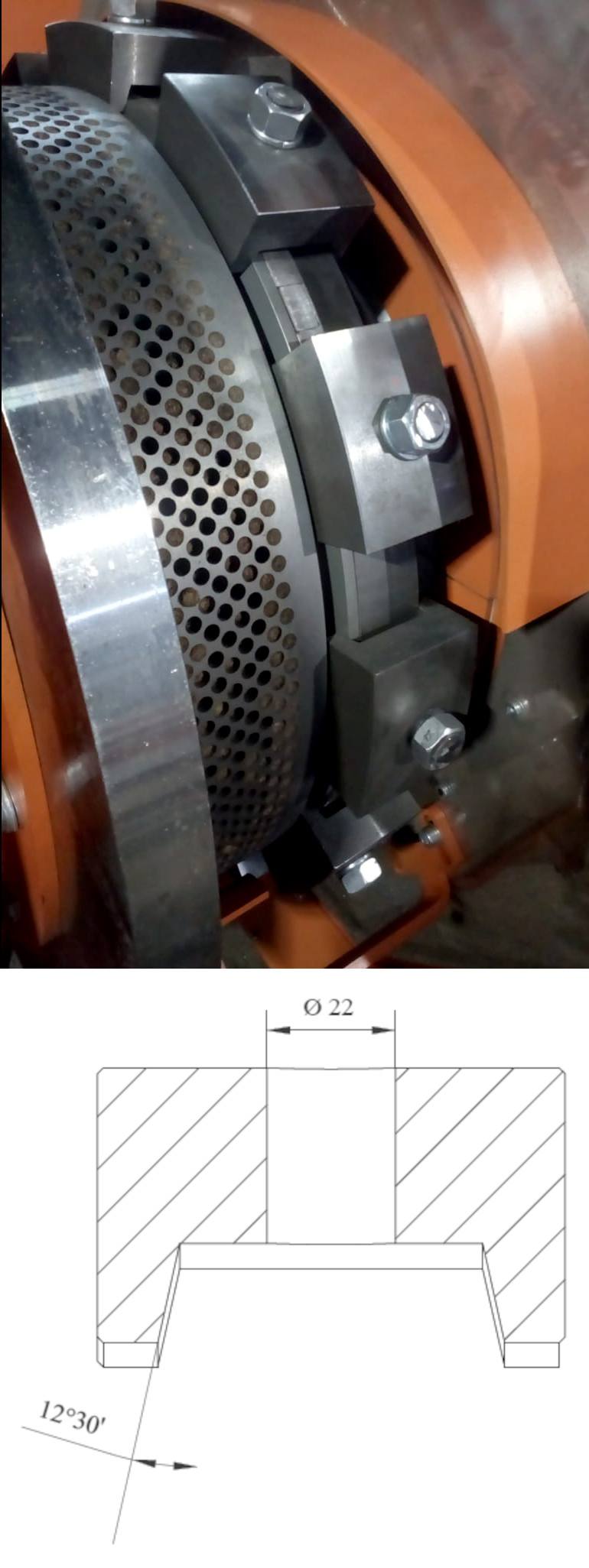

The attachment of the movable ring die is implemented differently depending on the pellet mill model. The complexity and peculiarity of this part of the pellet mill lie in the limited diameter of the already wide mounting flange when under tension, while the loads on this connection are nearly the highest throughout the entire unit. The die, when fitted cylindrically into the mounting flange, is secured by clamps externally. Both the die and the edge of the mounting flange feature tapered surfaces with an angle of 12-15°. A clamp has a matching counterpart, which, when the nuts are tightened, pulls the die in. The cylindrical fitting takes on the primary load, while the clamp merely keeps components in the desired position and usually cannot bear the significant loads transferred from the rollers.

The attachment of the movable ring die is implemented differently depending on the pellet mill model. The complexity and peculiarity of this part of the pellet mill lie in the limited diameter of the already wide mounting flange when under tension, while the loads on this connection are nearly the highest throughout the entire unit. The die, when fitted cylindrically into the mounting flange, is secured by clamps externally. Both the die and the edge of the mounting flange feature tapered surfaces with an angle of 12-15°. A clamp has a matching counterpart, which, when the nuts are tightened, pulls the die in. The cylindrical fitting takes on the primary load, while the clamp merely keeps components in the desired position and usually cannot bear the significant loads transferred from the rollers.

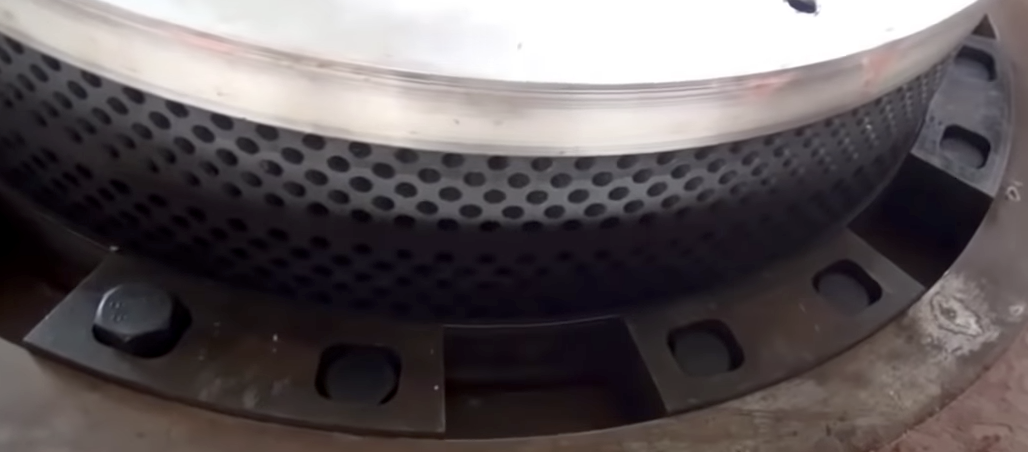

There are two types of clamps: ring clamps with tangential fastening and segmented clamps with radial studs. Ring clamps consist of two or three parts and are tightened together by two or three bolts. This is the weakest option, and these clamps are consumables, lasting for 3-5 die replacements. Segment clamps are tightened by individual studs and are more reliable. This type takes on part of the load, significantly reducing wear on the mounting flange, which is almost the most expensive part of the pellet mill. In some American pellet mills, each segment is secured with three studs: one in the middle has a trapezoidal thread to maximize the clamping force of the clamp, and two others secure the segment, preventing micro-movements and wear from micro pitting. In the photo to the right, the die is secured with segment clamps, and non-hardened M20 studs are sufficient to deform the die if the nuts are overtightened.

There are two types of clamps: ring clamps with tangential fastening and segmented clamps with radial studs. Ring clamps consist of two or three parts and are tightened together by two or three bolts. This is the weakest option, and these clamps are consumables, lasting for 3-5 die replacements. Segment clamps are tightened by individual studs and are more reliable. This type takes on part of the load, significantly reducing wear on the mounting flange, which is almost the most expensive part of the pellet mill. In some American pellet mills, each segment is secured with three studs: one in the middle has a trapezoidal thread to maximize the clamping force of the clamp, and two others secure the segment, preventing micro-movements and wear from micro pitting. In the photo to the right, the die is secured with segment clamps, and non-hardened M20 studs are sufficient to deform the die if the nuts are overtightened.

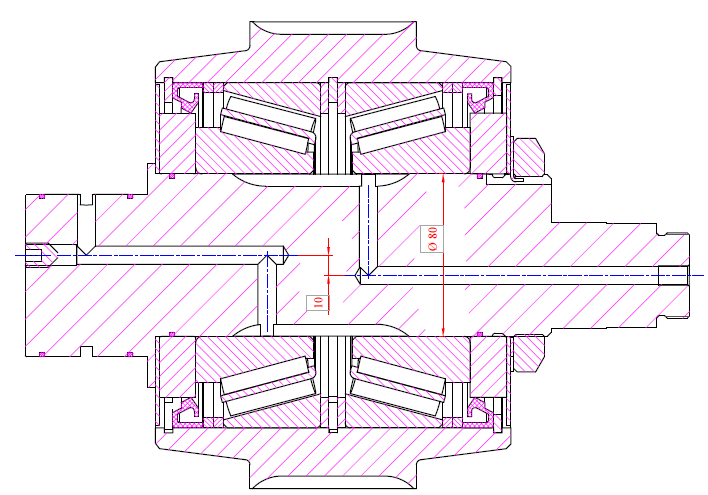

When suddenly supplying wet and cold raw material to an overheated die, it can cool down to 20–30°C (68–86°F), while the mounting flange remains around 100°C (212°F). Cooling of the die leads to a reduction in its diameter by 0.2-0.3mm (0.008-0.012 inches), resulting in play in the connections, and the key of the die can be heard hitting with each rotation. This leads to rapid wear of the fitting diameters and even breaking of the key. Even a new die may crack under such play, causing unexpected losses. The simplest way to avoid this issue is to make the fitting with a 0.2mm (0.008 inches) interference so that no slack appears when the die cools inside the mounting flange. To install the die, the mounting flange needs to be heated to 80-90°C (176-194°F), about 70°C (158°F) more than the die temperature. Replacement is simpler: heat the pellet mill to the operating temperatures with the old die, remove the old die, and immediately install a new cold die in the hot mounting flange. Extraction of the die is relatively simple using two opposing wedges in the free key slot.

Combatting the effects of temperature fluctuations is aided by a conical seating of the die. The die is drawn into the cone of the mounting flange with bolts, and its perpendicularity to the shaft axis is controlled with a micrometric indicator. The installation process can take up to 2 hours, but it is a more forgiving and predictable option. Extraction is done by pressing out through special holes in the mounting flange. Such dies are usually made symmetric, so the fitting of the reinforcing ring on the front is done in the same manner. Moreover, with uneven wear of the near and far rows, the die can be flipped with each roller replacement without leveling and track restoring procedures.

Combatting the effects of temperature fluctuations is aided by a conical seating of the die. The die is drawn into the cone of the mounting flange with bolts, and its perpendicularity to the shaft axis is controlled with a micrometric indicator. The installation process can take up to 2 hours, but it is a more forgiving and predictable option. Extraction is done by pressing out through special holes in the mounting flange. Such dies are usually made symmetric, so the fitting of the reinforcing ring on the front is done in the same manner. Moreover, with uneven wear of the near and far rows, the die can be flipped with each roller replacement without leveling and track restoring procedures.

Sometimes these methods are combined by using a die with a cylindrical fit and a conical fit in the mounting plate. Between them, a ring with a cross-section in the shape of a rectangular trapezoid is inserted. This ring is a consumable part that protects the expensive shaft from wear.

Sometimes these methods are combined by using a die with a cylindrical fit and a conical fit in the mounting plate. Between them, a ring with a cross-section in the shape of a rectangular trapezoid is inserted. This ring is a consumable part that protects the expensive shaft from wear.

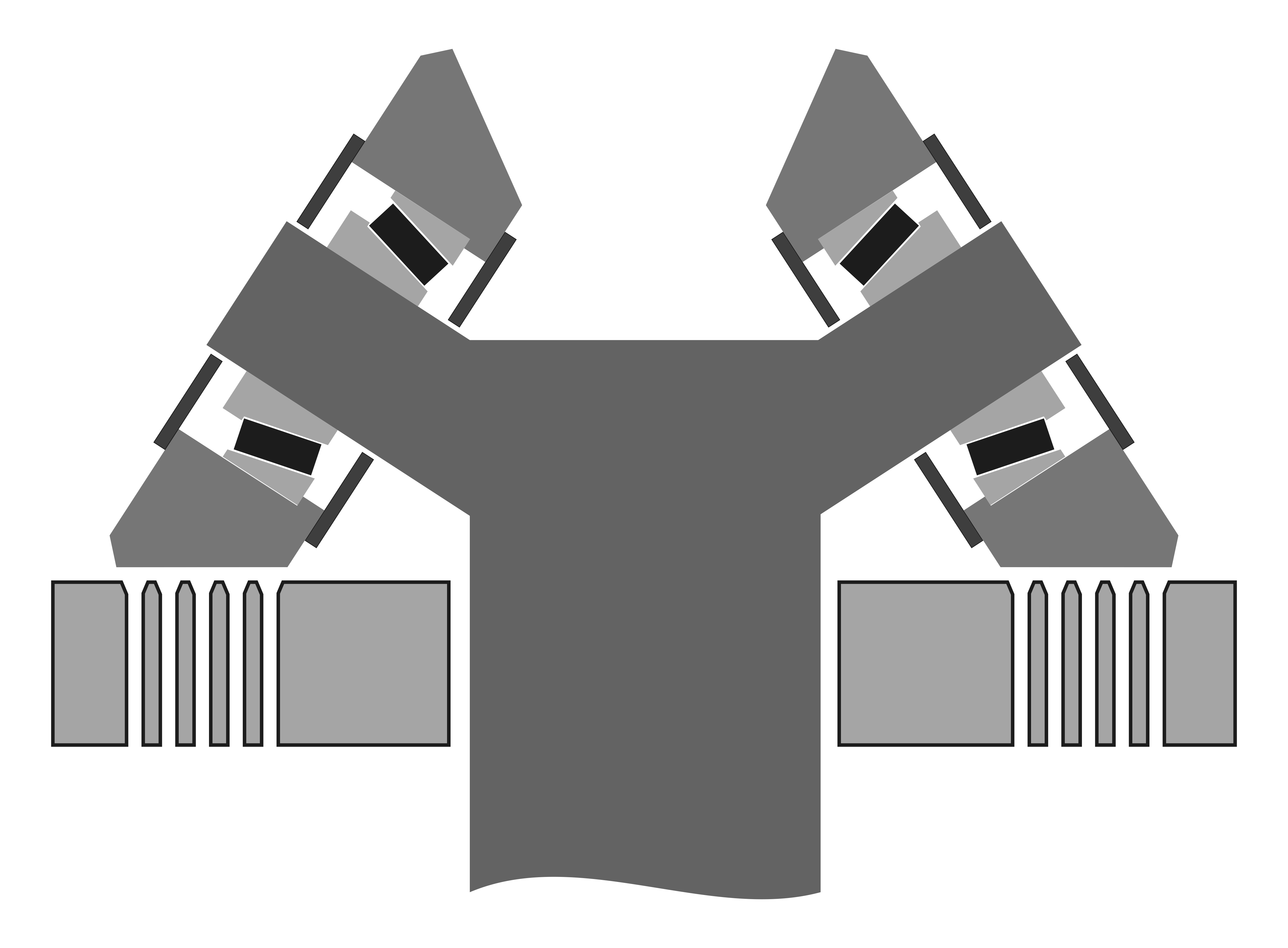

For mounting a stationary ring die, they typically use simpler methods since there is ample space on the pellet mill frame. The most popular method is the insertion of wedges around the perimeter. This is the best resource-saving method, provided there is sufficient rigidity in the body, which is made from a plate with a conical cutout attached to the gearbox.