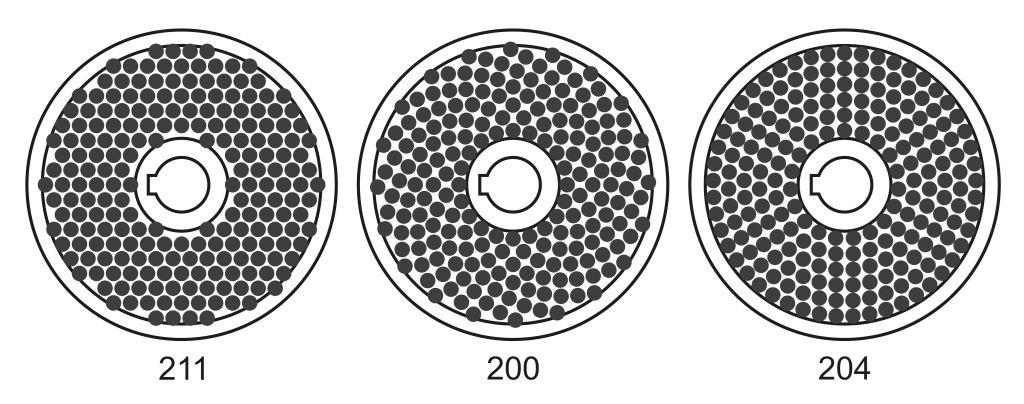

Typically, in pellet production, the raw material is pressed through the holes of the die, which determine the diameter of the pellets. The length of the pellets is ideally determined by the distance of the knife from the die. The term knife is a conditional name because this device does not cut but breaks the pellets when they grow from the die to the specified length.

Typically, in pellet production, the raw material is pressed through the holes of the die, which determine the diameter of the pellets. The length of the pellets is ideally determined by the distance of the knife from the die. The term knife is a conditional name because this device does not cut but breaks the pellets when they grow from the die to the specified length.

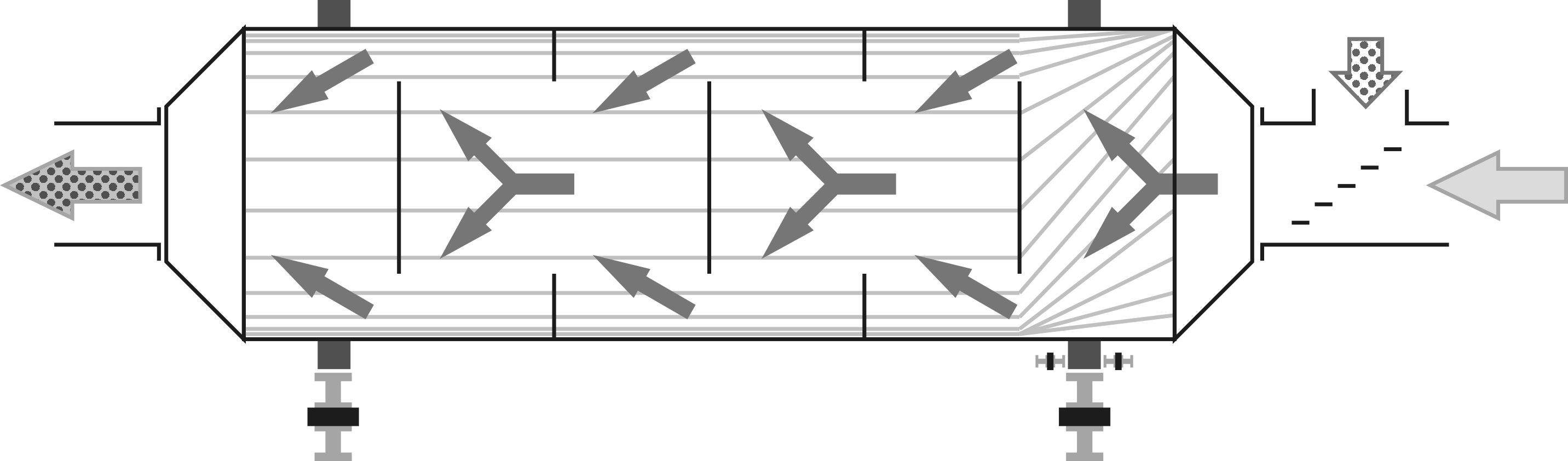

The pressing through the die occurs with the help of rollers that spread the raw material across the perforated surface of the die, known as its track. The replaceable outer part of the rollers is called the shell, and its working surface has special grooves or dimples. The working surface of the shell, referred to as the shell's track, is usually 4-6 mm (0.2 inches) wider than the track of the die to ensure the overlapping of the outer rows of holes. During the spreading of the raw material, several processes happen simultaneously:

- Compaction of particles with the release of air from the pores

- Grinding of particles by the grooves on the rollers' surface

- Heating of the raw material through mechanical action

- Distribution of moisture between neighboring particles

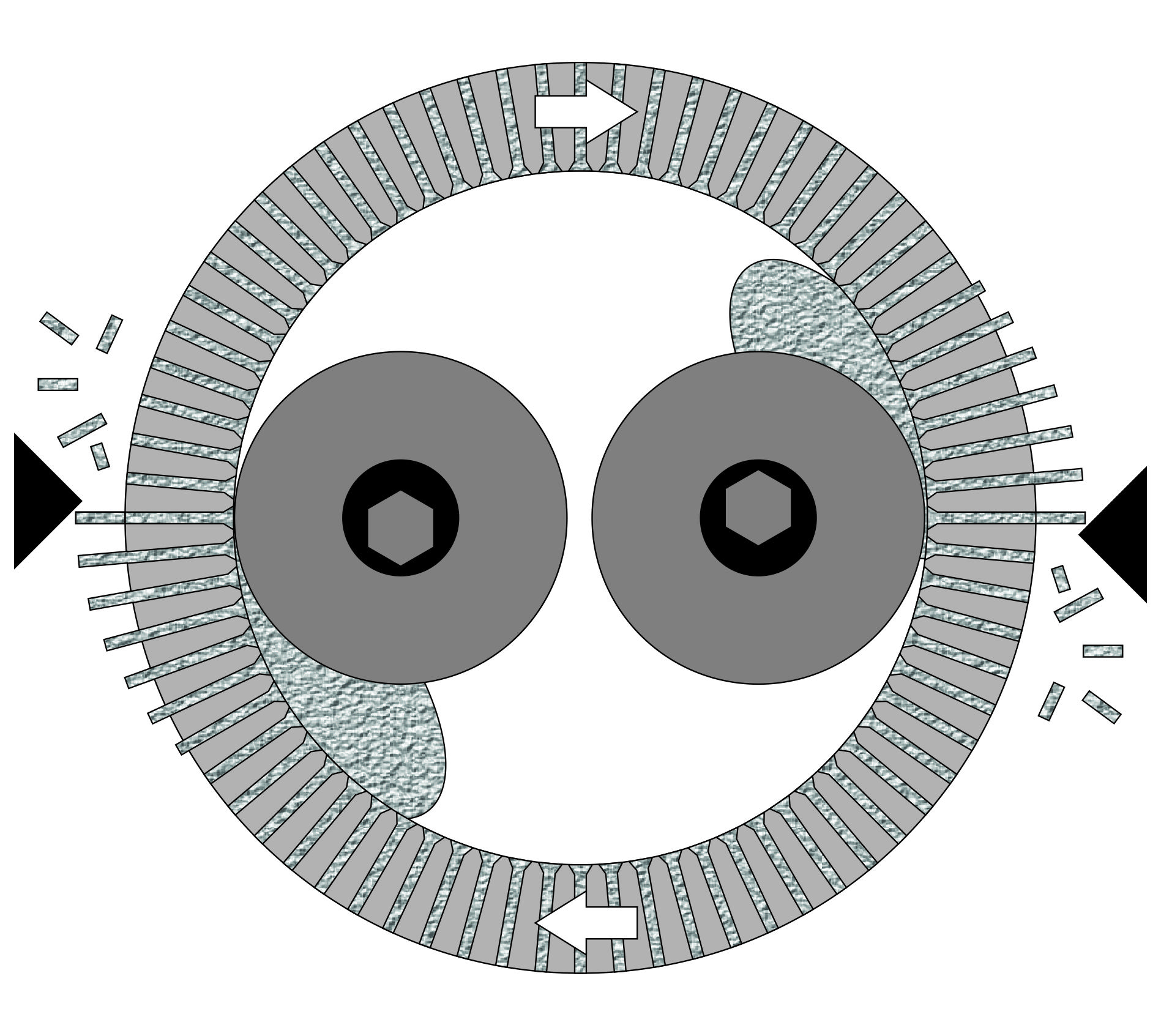

Depending on the type of raw material, its preparation degree, and other features, some of these processes may dominate over others. For instance, in the pelletizing of relatively dense and sticky materials like animal feed, green grass, or manure, mainly compression between particles with subsequent pressing occurs, and sufficient heating for sterilization is difficult, hence steam treatment is applied. Productivity is determined by the ability to capture the raw material by the grooves on the shells, which for maximum throughput are designed in a crescent or herringbone pattern. This arrangement of grooves prevents the expulsion of material from under the roller, much like mud from under a car wheel.

Depending on the type of raw material, its preparation degree, and other features, some of these processes may dominate over others. For instance, in the pelletizing of relatively dense and sticky materials like animal feed, green grass, or manure, mainly compression between particles with subsequent pressing occurs, and sufficient heating for sterilization is difficult, hence steam treatment is applied. Productivity is determined by the ability to capture the raw material by the grooves on the shells, which for maximum throughput are designed in a crescent or herringbone pattern. This arrangement of grooves prevents the expulsion of material from under the roller, much like mud from under a car wheel.

For processing mixtures containing fusible powdery additives for bonding, heating during the 'chewing' of the raw material is most significant. Notable examples include rubber crumb with bitumen powder, MDF waste, RDF, and resinous wood waste. During chewing, the particles undergo slight melting and bonding. However, premature heating of the raw material leads to its sticking to the equipment's working parts before pelletizing and clogging the cavities inside the units. Too rapid passage of the raw material at high feeds leads to insufficient heating and cessation of bonding. Sometimes to intensify mixing and heating with bitumen, the length of the working channel is halved, and the size of teeth on the rollers is increased. It also helps to use not pure bitumen but supply bitumen emulsion through sprayers, similar to wetting the raw material. Especially critical is uniform mixing when producing additives in asphalt from cellulose or tire cord fibers, which are waste during the processing of tires into rubber crumb.

Wood and similar types of biomass have intermediate properties. In most cases, they require heating to 80-90°C (176-194°F), at which hardness decreases 5-8 times, and redistributed evaporating moisture begins to interact with lignin and other components, giving them lubricating and adhesive properties. For a production rate of 1 ton per hour, about 20-50 kWh of energy is spent only on heating, so using already hot raw materials from the dryer significantly reduces energy consumption and increases productivity. For the same purpose, steam heating and closed pneumatic transport circuits of the hammer mill are used to reduce thermal losses.