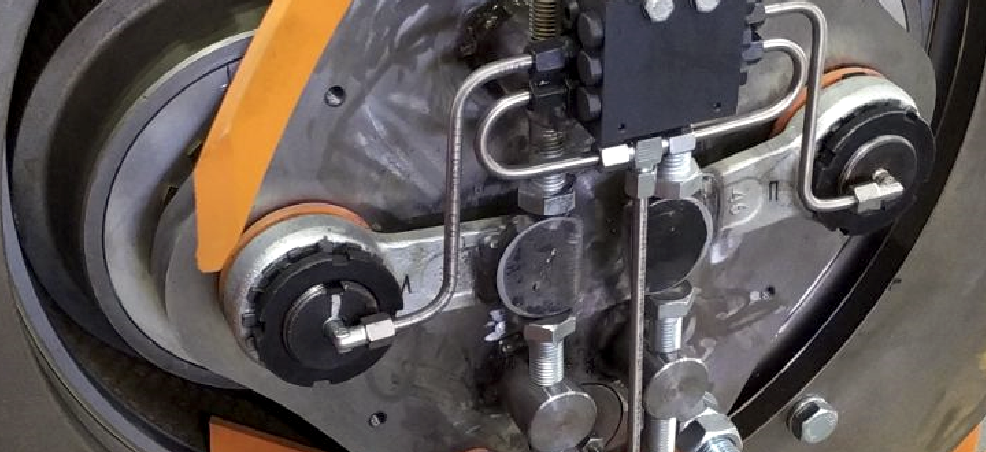

Special attention is given to the connection of the axle with the lever that sets its position. The most popular is a relatively expensive spline connection, capable of bearing maximum load with minimal diameter. In the OGM-1.5 pellet mill, a toothed connection of the lever with a bushing is used, which in turn is fitted onto a key on the eccentric, acting as a breakaway protection for the lever. These designs allow repositioning the lever in various positions with minimal increments, enhancing the range of adjustment. However, a weak key under impact loads deforms and shears rapidly. Fine serrations on the levers quickly wear out and weaken under variable loads and chemically aggressive water vapors and organic acids.

It’s not possible to apply a simpler, cheaper, and more reliable square connection like on a safety device because the maximum repositioning step allowed is within 30 degrees. On a square, the minimum step is 45 degrees, and too much material is removed by the four flats on the shaft, and the levers themselves require sufficient precision and are not much cheaper when custom-made.

It’s not possible to apply a simpler, cheaper, and more reliable square connection like on a safety device because the maximum repositioning step allowed is within 30 degrees. On a square, the minimum step is 45 degrees, and too much material is removed by the four flats on the shaft, and the levers themselves require sufficient precision and are not much cheaper when custom-made.

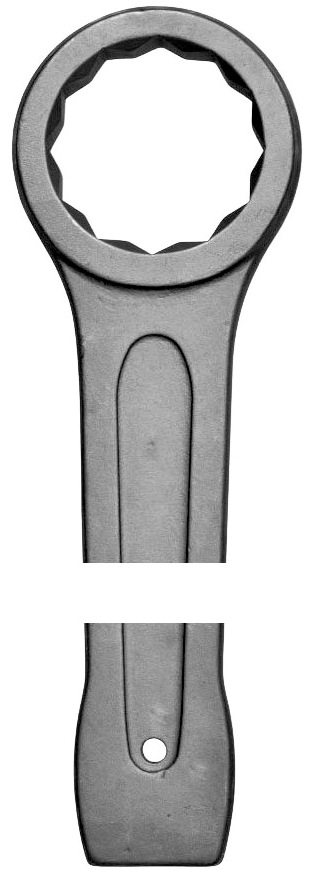

As a result, the ends of the eccentrics in the GRACH-480 pellet mill were made in the shape of a hexagon to match a standard socket wrench size. Ordinary impact socket wrenches are used as levers, shortened to the necessary length and with welded pads for engaging with the adjustment bolt. Impact wrenches are used because they can withstand critical loads. Welded nuts holding the adjustment bolts are intentionally made thicker and taller so that ordinary standard bolts from the nearest store can be used. The bolt heads need to have the engraved numbers ground off so they don't prevent a tight fit with the pads welded onto the levers. Thus, for repairing this device, visiting a truck parts store is sufficient. It's important to note that the hex on the axle is deliberately made slightly oversize, as wrench sizes are typically slightly oversize.

As a result, the ends of the eccentrics in the GRACH-480 pellet mill were made in the shape of a hexagon to match a standard socket wrench size. Ordinary impact socket wrenches are used as levers, shortened to the necessary length and with welded pads for engaging with the adjustment bolt. Impact wrenches are used because they can withstand critical loads. Welded nuts holding the adjustment bolts are intentionally made thicker and taller so that ordinary standard bolts from the nearest store can be used. The bolt heads need to have the engraved numbers ground off so they don't prevent a tight fit with the pads welded onto the levers. Thus, for repairing this device, visiting a truck parts store is sufficient. It's important to note that the hex on the axle is deliberately made slightly oversize, as wrench sizes are typically slightly oversize.

The largest pellet mills use an advanced mechanism with a single screw and two-step worm gear drive to move the levers synchronously, ensuring even wear. Sometimes a mechanism similar to an automotive hydraulic valve lifter is used. On smaller home pellet mills, washers with slots and set screws may be used instead of levers, improving adjustment precision and reducing mounting rigidity.