In the pressing unit, the rotation speed of the ring die relative to the rollers is usually between 110 and 300 rpm. Given that the most affordable and mass-produced standard industrial motors have a minimum rotation speed starting at 700 rpm, a gear reduction is necessary.

The most popular for industrial pellet mills with a capacity of 500 kg (1102 pounds) per hour of wood pellets is a cylindrical gearbox with one or two stages of gear transmission. These gearboxes offer the best resource-to-cost ratio due to their relative simplicity of manufacturing.

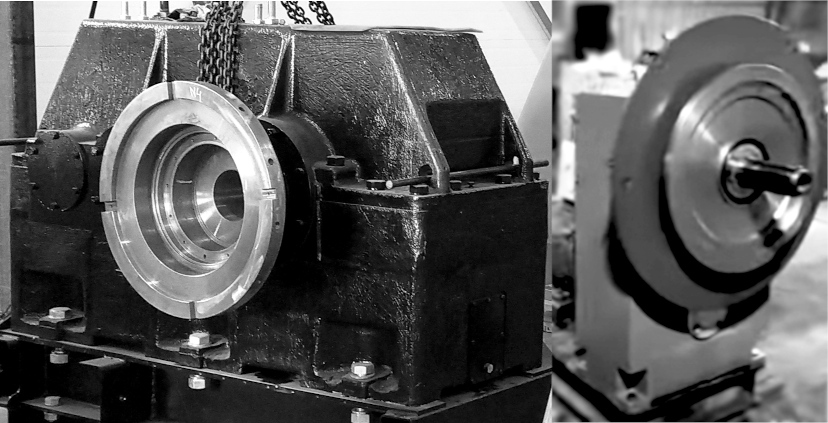

The choice between a single-stage and two-stage gearbox depends on several factors specific to production conditions. A ring die typically requires between 140 and 220 rpm, let's use 180 rpm as on the GRACH-480 pellet mill. To achieve this speed with a motor of 1440 rpm, a gear ratio of 1:8 is required. For the OGM-1.5 pellet mill with its 140 rpm and the same type of motor, a 1:10 gear ratio is necessary. The gear diameter ratio in each stage is approximately 1:3, which is optimal for durability even with relatively low-quality gear manufacturing. The photo shows the gearboxes of these pellet mills for size comparison, as they use ring dies of the same diameter.

To maintain the gear diameter ratio and move to a single-stage gearbox, a motor with 700 rpm must be used, leading to a noticeable price increase. The price of the gearbox will be similar, but the motor will be nearly twice as expensive. Another difference between the two pellet mills is that the GRACH-480 uses a standard serial gearbox Ts2N-500 with horizontal axis positioning. The large gears of each stage are immersed in an oil bath to ensure thorough lubrication of the teeth and ample splash lubrication to the bearings. However, in the OGM-1.5, the axes are vertically positioned, and a special paddle is often used on the fast shaft to scoop oil onto the largest upper teeth. Originally an oil pump was used for lubrication of the upper gears and bearings as well as to supply oil to the central bearing of the pressing unit. However, its short lifespan in low-maintenance conditions led to such modification, reducing the reliability of the unit.

To maintain the gear diameter ratio and move to a single-stage gearbox, a motor with 700 rpm must be used, leading to a noticeable price increase. The price of the gearbox will be similar, but the motor will be nearly twice as expensive. Another difference between the two pellet mills is that the GRACH-480 uses a standard serial gearbox Ts2N-500 with horizontal axis positioning. The large gears of each stage are immersed in an oil bath to ensure thorough lubrication of the teeth and ample splash lubrication to the bearings. However, in the OGM-1.5, the axes are vertically positioned, and a special paddle is often used on the fast shaft to scoop oil onto the largest upper teeth. Originally an oil pump was used for lubrication of the upper gears and bearings as well as to supply oil to the central bearing of the pressing unit. However, its short lifespan in low-maintenance conditions led to such modification, reducing the reliability of the unit.

On the CPM 3000 series pellet mill, the gear transmission ratio is approximately 1:7 and features a single-stage gearbox. Ignoring the motor cost, this setup has several advantages. Firstly, it reduces the number of parts in the gearbox and simplifies maintenance. Secondly, instead of two stages with relatively narrow gears, it employs a single transmission with much wider gears featuring fine helical teeth, engaging multiple teeth simultaneously. This ensures maximum operational smoothness, reducing vibration and noise. Thirdly, the vertical single-stage transmission with a lower fast shaft provides simple and reliable gear tooth lubrication with high efficiency. The manufacturing challenge is in selecting the ideal chemical composition and hardness of the gears, as the faster gear experiences contact seven times more frequently and requires greater wear resistance. Unscrupulous imitators failed to recognize this when they began copying the design using raw gears and shafts, shortening the lifespan to 3-5 months instead of the usual 7-10 years for such machines.

For a cylindrical gear with a usual width, it is quite straightforward to estimate the approximate service life and reliability by comparing it with standard gearbox models based on catalog sizes and rated loads. For wide gears, you can roughly calculate the allowable load proportionally to the increase in tooth length. On the OGM-1.5, the distance between the axes of the second gear is 308 mm (12 inches), the nearest gearbox to this is the Ts2N-315 with a nominal torque of 8000 N/m. The nominal torque of the 75 kW motor at 1440 rpm is 500 N/m, which means with the gearbox reduction 1:10, you get an output of 5000 N/m and an initial service factor of 1.5 seems encouraging. However, upon closer examination of the operating conditions, it turns out that such a configuration is well suited for screw conveyors but not for impact variable loads that occur regularly in pellet production. Thus, with sufficiently high-quality gear manufacturing and careful handling, there is a 95% probability that the pellet mill gearbox will work reliably for at least 1 year in round-the-clock operation, and when operating in one shift, this period increases to three years. When plagiarizing this press, not only did the production quality drop significantly, but engines of 90, 110, and even 132 kW began to be installed on raw shafts, renaming the units into their own variants. This trick greatly helped marketers because they started comparing the price with reliable specimens of similar power. If the 75 kW motor is used in a regular mode at 70-80% of the nominal, or 100-110 Amperes at 380 V, attempts to operate with larger engines at a load of 170-200 Amperes very quickly lead to the destruction of the gearbox and pressing unit. As a result, purchasing a nominally powerful press only leads to excessive energy consumption because the efficiency of an industrial electric motor reaches 90% only when the load is above 50% of the nominal. A very similar picture occurs when plagiarizing initially feed pellet mills designed for high rpm of the pressing unit and low loads. Supplying sawdust to them leads not only to a decrease in productivity several times but also to rapid wear with unscheduled repairs, which fundamentally kills the hope for production profitability.

The gearbox Ts2N-500 has a nominal torque of 45 kN/m, and the nominal torque on the ring die of the GRACH-480MP pellet mill (132 kW) is 7 kN/m, meaning the service factor is 6.4, which isn’t that much. For impact loads in round-the-clock operation, a service factor of at least 2 is needed for almost guaranteed operation for 1 year without repair. The service factor’s value is approximately in a quadratic relationship with the service life. That is, increasing the service factor three times theoretically gives hope for 9 years of operation, although over such terms, the regularity of maintenance has a much greater influence, and given the rough machining of the gears, it is quite normal to expect 5-7 years of regular operation considering stops, seasonality, and other non-mechanical factors.

A worm gearbox for the pellet mill might seem outrageous to the chief engineer in production, however, Kahl surprised the whole world. Unusual solutions generally come from specific experience, and they managed to create a sufficiently reliable pellet mill with surprisingly high efficiency. On one hand, worm gearboxes are known for somewhat higher losses compared to cylindrical ones. On the other hand, obtaining relatively low speeds with massive rollers allows for squeezing the sawdust through the die steadily and without overheating. Thus, by optimizing the worm gear geometry, they achieved a large reliable pellet mill, which due to the high cost of spare parts, should simply be replaced with a new one after 8-10 years, having long recouped the costs.

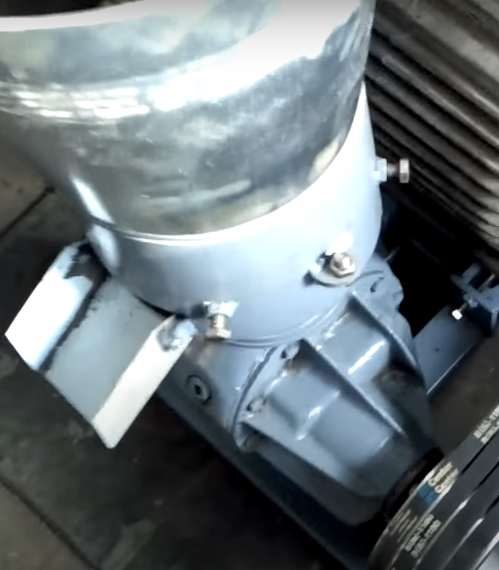

The use of hypoid gears, adapted from the automotive industry, has become very widespread. Essentially, they took the original rear axle reducer, connected the engine instead of the drive shaft, and placed the pellet mill shaft instead of the axle shaft. If the loads are calculated correctly, this type of gear is quite reliable and low-noise. Considering the low cost of spare parts, it has become popular for semi-domestic models, even more than belt drives, which sometimes remain for speed adjustment or simply as a way of connecting to the engine. During adaptation, special attention is paid to thrust bearings installed in the transition section, as well as sealing to prevent raw material from entering the reducer. In the low-cost segment, special protective devices are not included, and their role is fulfilled by the same V-belts or coupling sleeves, selected precisely for the maximum allowable torque as the cheapest and easily replaceable parts.

The use of hypoid gears, adapted from the automotive industry, has become very widespread. Essentially, they took the original rear axle reducer, connected the engine instead of the drive shaft, and placed the pellet mill shaft instead of the axle shaft. If the loads are calculated correctly, this type of gear is quite reliable and low-noise. Considering the low cost of spare parts, it has become popular for semi-domestic models, even more than belt drives, which sometimes remain for speed adjustment or simply as a way of connecting to the engine. During adaptation, special attention is paid to thrust bearings installed in the transition section, as well as sealing to prevent raw material from entering the reducer. In the low-cost segment, special protective devices are not included, and their role is fulfilled by the same V-belts or coupling sleeves, selected precisely for the maximum allowable torque as the cheapest and easily replaceable parts.