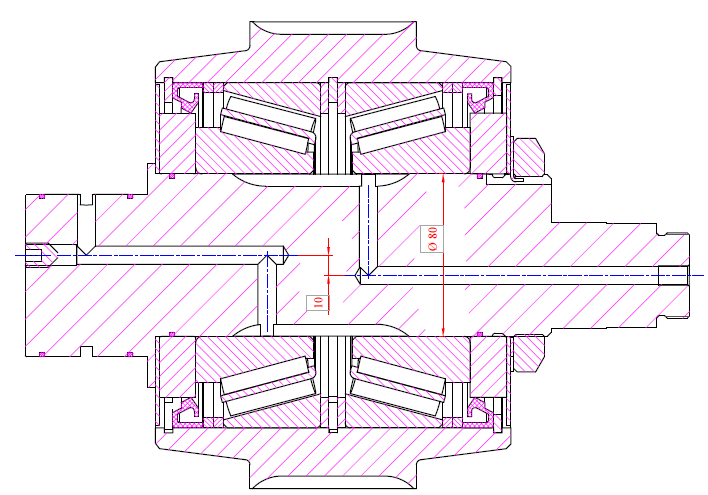

The shape of the hammer depends on the working conditions and material properties. If each hammer corresponds to 1 kW of installed power, the hammer mill is capable of working continuously, with the hammer diving into the material. This is a classic example for grain hammer mills, where a rectangular hammer with two holes is used, with a distance of 30-50 mm (1-2 inches) from the hole to the edge of the hammer. Almost all this space is intended for grinding against the material. Grains and various feeds have low strength and abrasiveness, so wear of the hammer by 10-20 mm (0.4-0.8 inches) from the edge has little impact on productivity. This shape is the most cost-effective for manufacturing consumable parts, as it results in minimal scraps and can be produced using a guillotine and a drilling machine.

The shape of the hammer depends on the working conditions and material properties. If each hammer corresponds to 1 kW of installed power, the hammer mill is capable of working continuously, with the hammer diving into the material. This is a classic example for grain hammer mills, where a rectangular hammer with two holes is used, with a distance of 30-50 mm (1-2 inches) from the hole to the edge of the hammer. Almost all this space is intended for grinding against the material. Grains and various feeds have low strength and abrasiveness, so wear of the hammer by 10-20 mm (0.4-0.8 inches) from the edge has little impact on productivity. This shape is the most cost-effective for manufacturing consumable parts, as it results in minimal scraps and can be produced using a guillotine and a drilling machine.

One should not skimp too much on the width of the hammer by reducing the width of the neck between the hole and the side surface. This width is usually 15-20 mm (0.6-0.8 inches), and if worn to less than 10 mm (0.4 inches), the hammer should not be installed. When the rotor speeds up to 3000 rpm, the centrifugal force exerted is comparable to a weight of 1-2 tons. A break in a deliberately weakened part can lead to a chain reaction of complete mutual destruction of all hammers, the rotor, and the hammer mill casing. At a speed of 100 m/s (328 ft/s) and a mass of about 200 grams (0.44 pounds), a hammer can punch through light constructions, leaving holes with a diameter of 100-200 mm (4-8 inches). Due to the extreme danger to life and health of personnel, it is also prohibited to start the mill with open covers and shutters. If a hammer has an unseen fatigue crack, the break can occur suddenly.

When crushing wood, straw, and similar sufficiently strong fibrous materials, there is an effort to increase the volume and area of the interior of the grinding chamber, as the material remains in it much longer. For each hammer, 0.5 kW of installed power is provided, which is the minimum acceptable value to avoid engine overload from excessive material feed. In this case, the corners and thin edge of the hammer do most of the work, and wear with rounding of the corner noticeably reduces productivity. For such materials, hammers are made with trapezoidal working sections, extending their service life by 1.5-2 times.

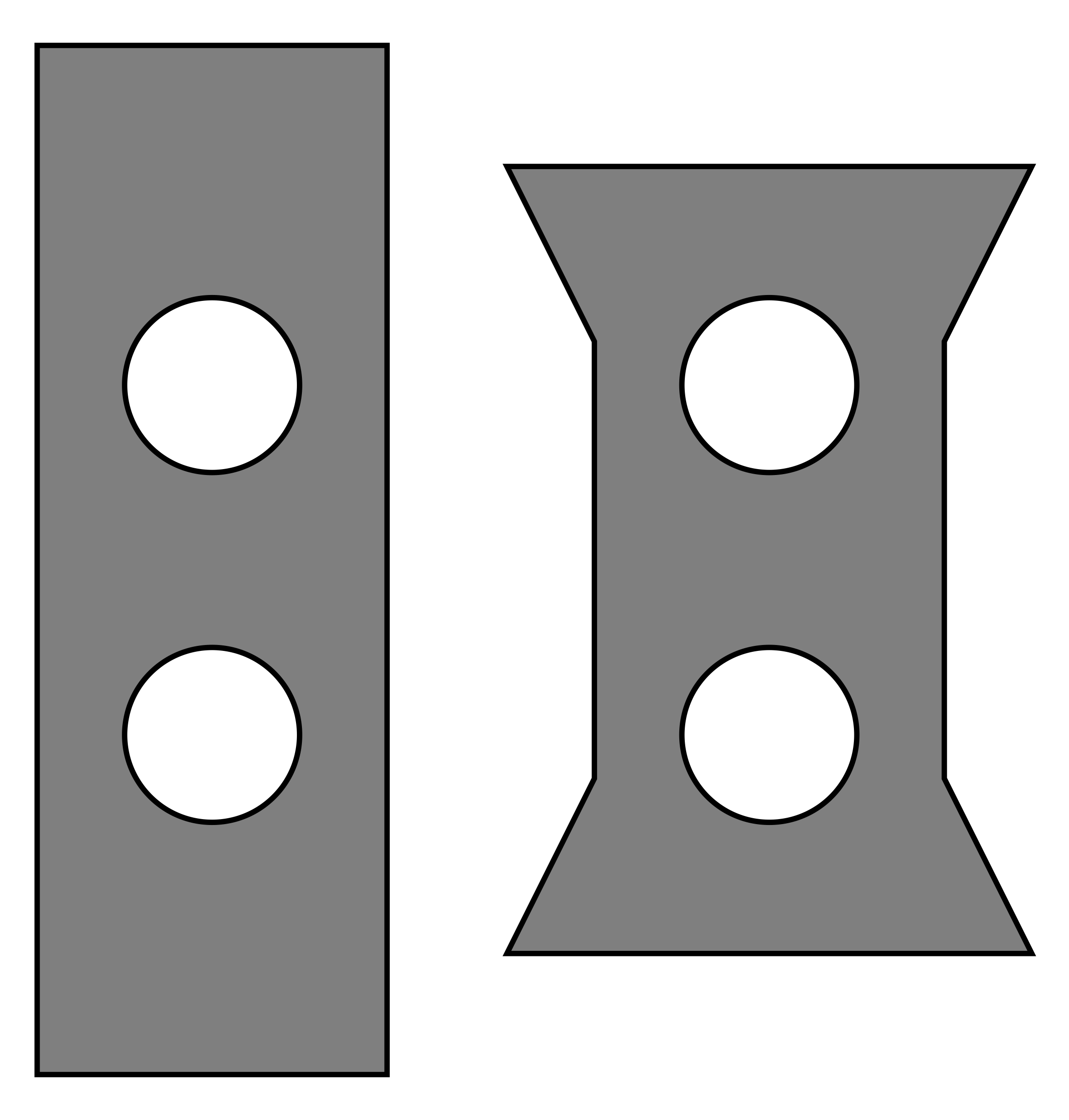

To increase the productivity of a small and inexpensive hammer mill, where the power on the hammers is excessive, a stepped hammer shape can be used. Increasing the number of angles promotes a greater volume of vortices and increases the useful mechanical load on the hammer. While the hammer's lifespan is reduced, it allows for high productivity when using a cheap machine occasionally. Hammers with grooves along the edge, which gradually form teeth during wear like the stepped hammer, have a noticeably longer life. When cutting carbon steel with a laser or plasma machine, the edge is shallowly hardened to a depth of 1-3 mm (0.04-0.12 inches), and the notches also improve the material's properties. This is relevant if the hammers are used without hardening.

To increase the productivity of a small and inexpensive hammer mill, where the power on the hammers is excessive, a stepped hammer shape can be used. Increasing the number of angles promotes a greater volume of vortices and increases the useful mechanical load on the hammer. While the hammer's lifespan is reduced, it allows for high productivity when using a cheap machine occasionally. Hammers with grooves along the edge, which gradually form teeth during wear like the stepped hammer, have a noticeably longer life. When cutting carbon steel with a laser or plasma machine, the edge is shallowly hardened to a depth of 1-3 mm (0.04-0.12 inches), and the notches also improve the material's properties. This is relevant if the hammers are used without hardening.

A thickness of 5 mm (0.2 inches) for hammers is optimal for grinding biomass intended as fuel. Using a thickness of 3-4 mm (0.12-0.16 inches) significantly reduces the lifespan due to small chips and particle breaks upon impact. Hammers with a thickness of 8-10 mm (0.31-0.39 inches) have a noticeably greater strength reserve and operational hours, but they noticeably reduce the hammer mill's productivity and overall grinding efficiency, increasing energy consumption.

For the hammers, the most popular steel from the available grades is 65G, also known as spring or leaf steel. Alloying with manganese (1%) and a relatively high carbon content (0.65%) provide the presence of microscopic cementite crystals with high hardness. This greatly improves wear resistance. This type of steel is quenched with a high tempering temperature to avoid maximum hardness, which significantly increases material brittleness. Serrations at the hammer edges using this steel are unsuitable, as they become too brittle without appropriate tempering and can break even when processing relatively soft materials.

The most wear-resistant steel grade for hammers and protective linings is Hardox 500, as well as its Russian equivalent, S500. These so-called "armor" steels are produced in sheets, which is convenient for manufacturing parts of any shape. Compared to untempered 65G steel, hammers made from armor have a lifespan 3 to 5 times longer. Although the material and consumables are more expensive, it is justified at facilities where the hammer mill requires more frequent maintenance than the rest of the equipment, disrupting the preventative maintenance schedule for the production line.

Hadfield steel 110G13 significantly excels even armor-grade steels in durability, but it is not produced in sheet form. Casting relatively small and thin hammers becomes too costly, which doesn’t justify the endeavor in terms of specific life span. The high cost of casting compared to CNC machining is due to the significant amount of manual labor involved in trimming gates and cleaning. Cast products vary more significantly in weight, making it much harder to assemble sets for ideal rotor balance.

A relatively inexpensive solution is using hardened bolts instead of hammers. A bolt with a diameter of 16mm (0.6 inches) and a length of about 100mm (4 inches) is comparable in mass to a typical crusher hammer. When distributed intelligently along the axes, the performance reduction is minimal. This construction has several advantages:

- The price of a hardened bolt is about three times lower

- Bolt purchase or order is possible in any city, relieving dependency on a single supplier for consumables

- High-strength bolts are made from manganese steels, similar to wear-resistant hammers

- In mass production, bolts have relatively small weight deviations, making it much easier to assemble a rotor with minimal imbalance

- The head shape is insignificant, and determining factors for selection are diameter and material hardness

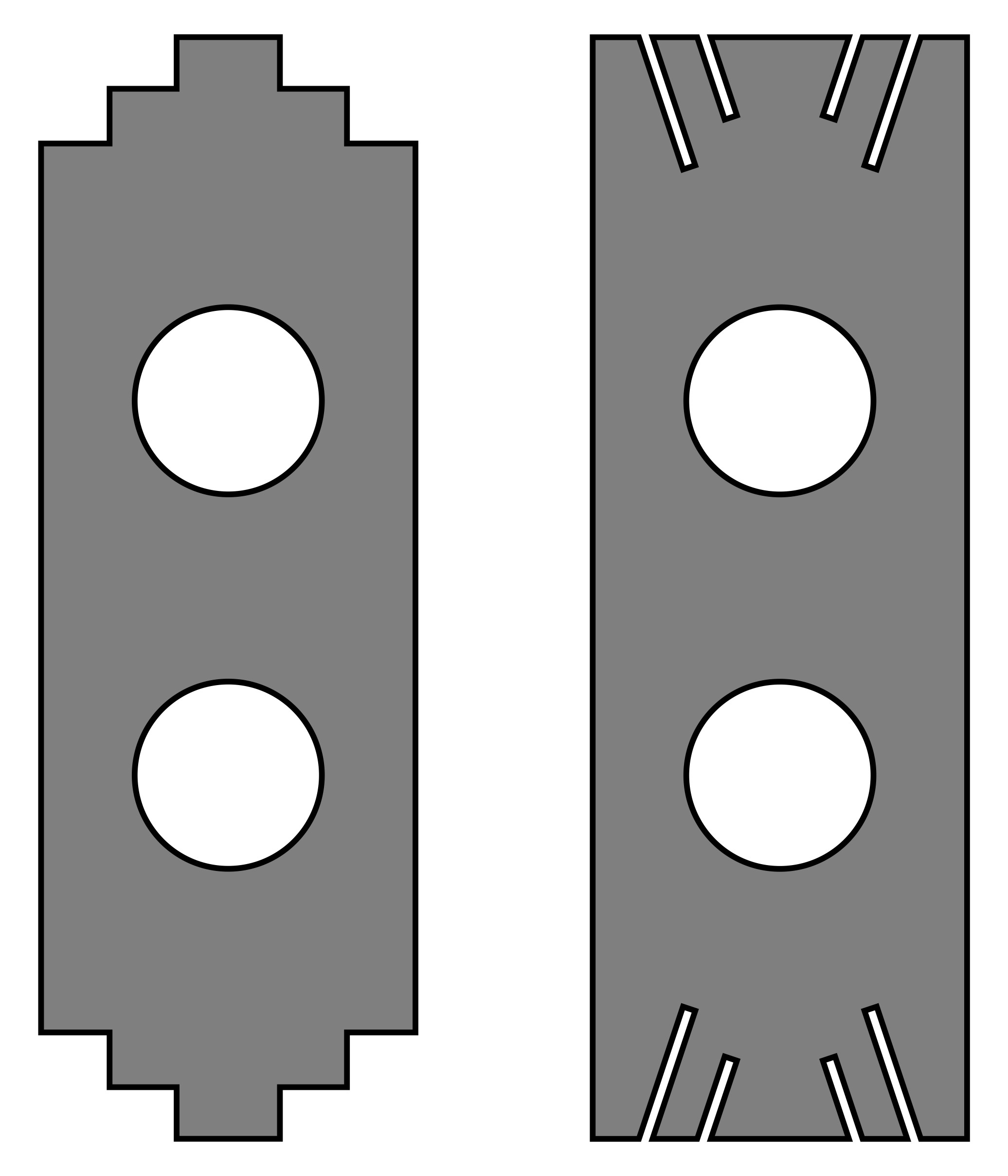

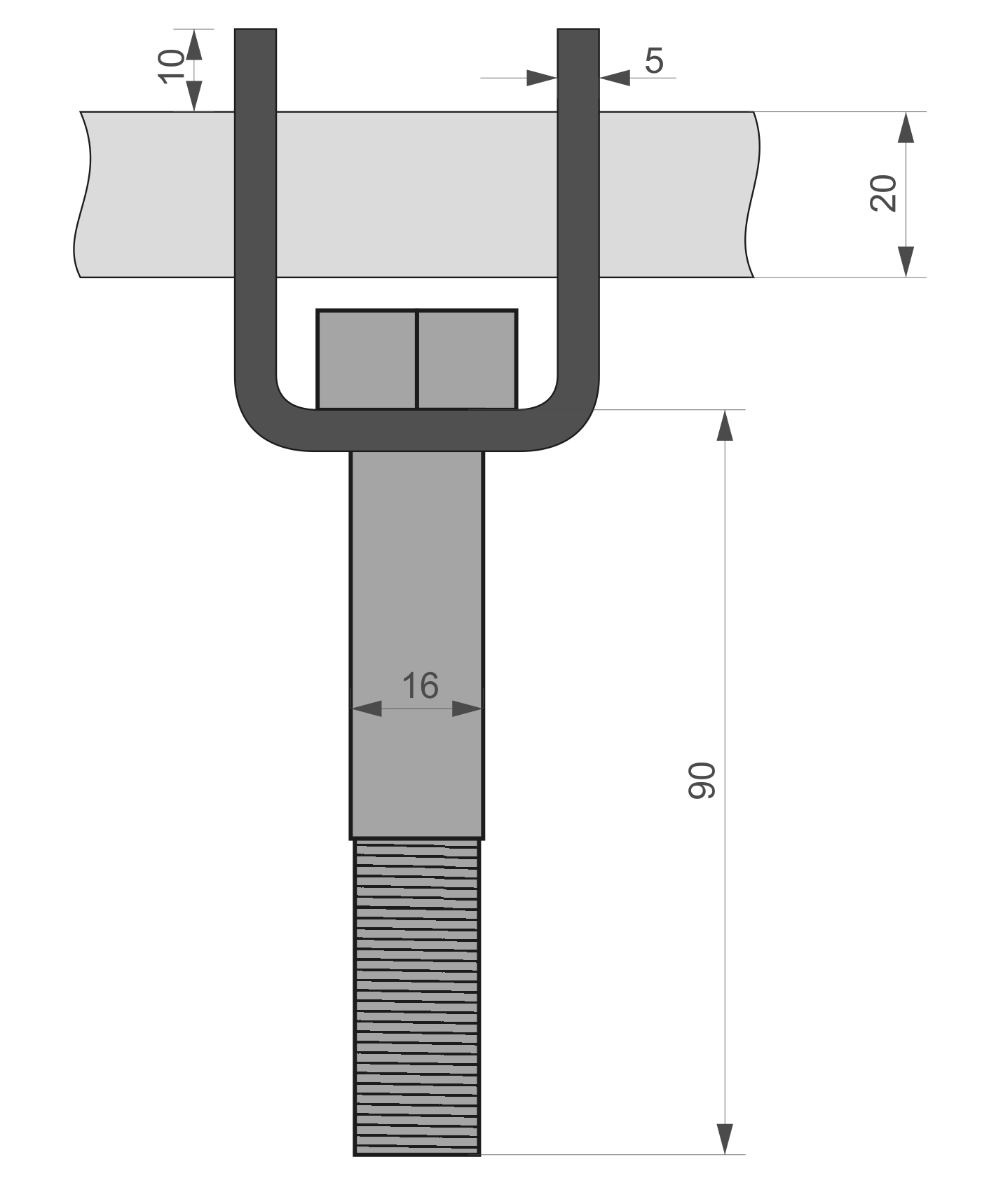

For installing bolts instead of hammers, brackets are used. These are shaped parts with three holes: two for threading onto the shaft and one for inserting the bolt. If the bending radius is larger than the part thickness, weakening along the bending line is insignificant. The placement of the holes is calculated from the minimum distance between the bolt head and the shaft, about 1-2mm (0.04-0.08 inches). This allows securing the bolt from falling out without additional mechanisms. The drawing shows approximate dimensions, and such a replacement should only be carried out after load testing and careful calculation of the eyelet width and sheet thickness.

For installing bolts instead of hammers, brackets are used. These are shaped parts with three holes: two for threading onto the shaft and one for inserting the bolt. If the bending radius is larger than the part thickness, weakening along the bending line is insignificant. The placement of the holes is calculated from the minimum distance between the bolt head and the shaft, about 1-2mm (0.04-0.08 inches). This allows securing the bolt from falling out without additional mechanisms. The drawing shows approximate dimensions, and such a replacement should only be carried out after load testing and careful calculation of the eyelet width and sheet thickness.

It is not recommended to install bolts upside down with nut welding. Although the head as a working surface would last longer, welding hardened parts behaves unpredictably and may require further heat treatment, negating any savings. Using a nut with a thread-locking feature or a crimping edge is also questionable in terms of reliability, as tangential impacts on the bolt head are likely to disrupt fixation. The complexity involved in assembly and disassembly could also negate any savings.