It's impossible to predict all "black swan" events, but some small details can cause enormous losses. They go unnoticed due to a lack of experience, loss of staff attention due to fatigue, lack of necessary tools, or simple carelessness.

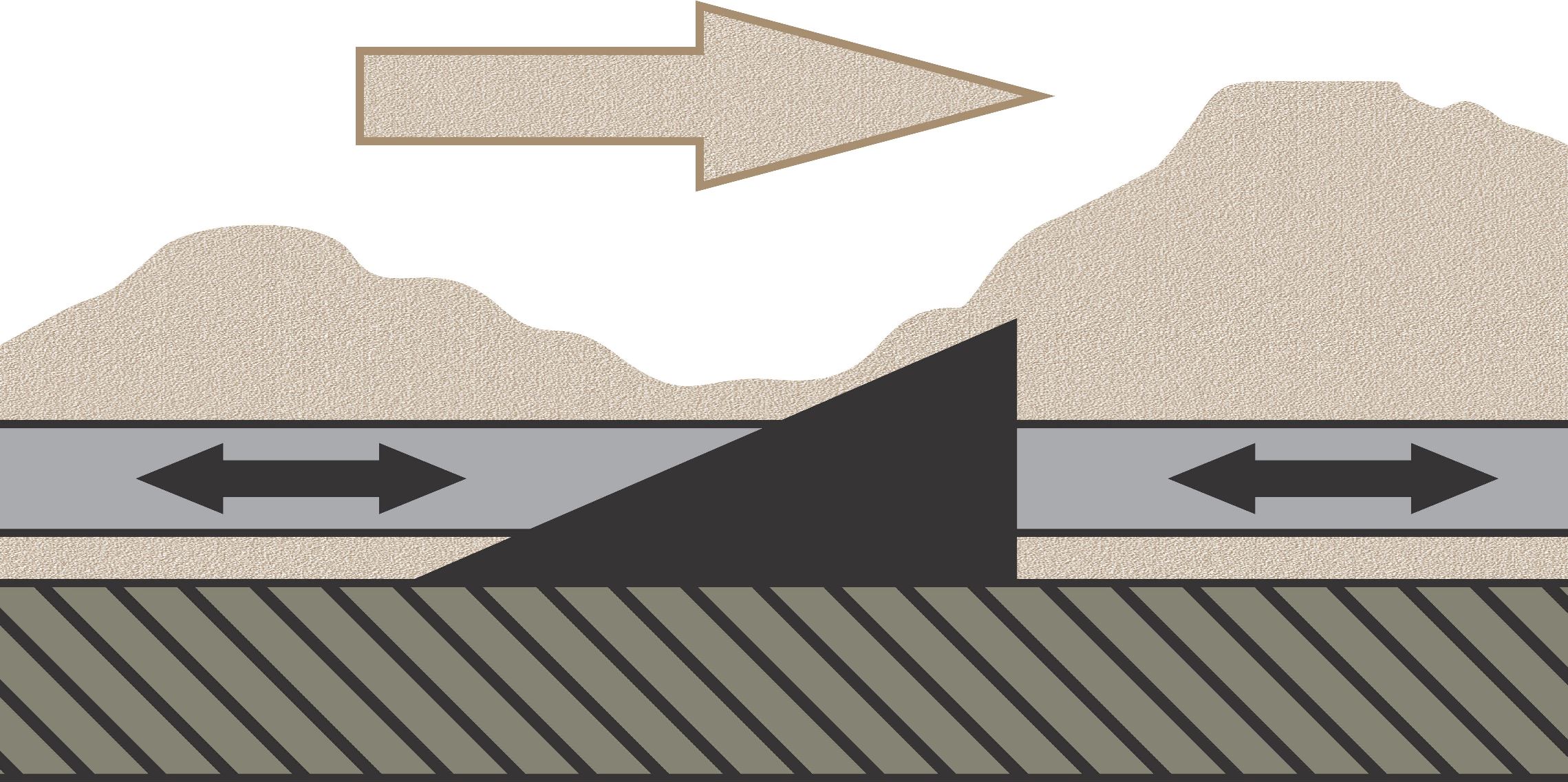

Runout of the Die Track

If the die track runout is more than 0.4 mm (0.016 inches), granulating wood becomes dangerous, as variable impact loads lead to fatigue cracks on the stationary shaft. Initially unnoticed, these cracks may allow for an additional 2-3 weeks of operation from the moment the die "settles," after which the shaft can completely break. A similar situation occurs with uneven gaps between the left and right roller from the die, or when attempting to operate with a roller that has a damaged bearing. Continued abuse of the pellet mill could result in the breaking of the flange plate near the gearbox housing. Runout is corrected using a grinding device for the track or by sending the die to specialized companies for machining.

Dust on Surfaces in the Workshop

If a flame is over 1 meter (3 feet) high, it creates a rather strong airflow. This airflow raises dust from surfaces, feeding itself with new batches of fuel, making such a fire unstoppable. Its spread rate can reach 3-5 meters per second (10-16 feet/s), and after covering a significant area and dislodging dust from roof trusses, a large explosion usually occurs, with catastrophic consequences. To prevent such situations, special attention should be given to the aspiration of all machines, and regular wet cleaning of the facility and equipment should be performed. This issue is important during the design phase, as it is much easier to initially plan for waterproof equipment and incorporate aspiration systems into the project from the start.

A visual experiment on fire safety was conducted. Half a bucket of shavings was dumped at the workshop exit during a draft, and a half-smoked cigarette was placed on top, with a stopwatch started. Within two minutes, the shavings were actively smoldering, and by the fourth minute, there was a flame. Applying this scenario to real production, where everything is covered in fine dust and someone tosses a cigarette butt into shavings, within five minutes, there's nothing left to save.

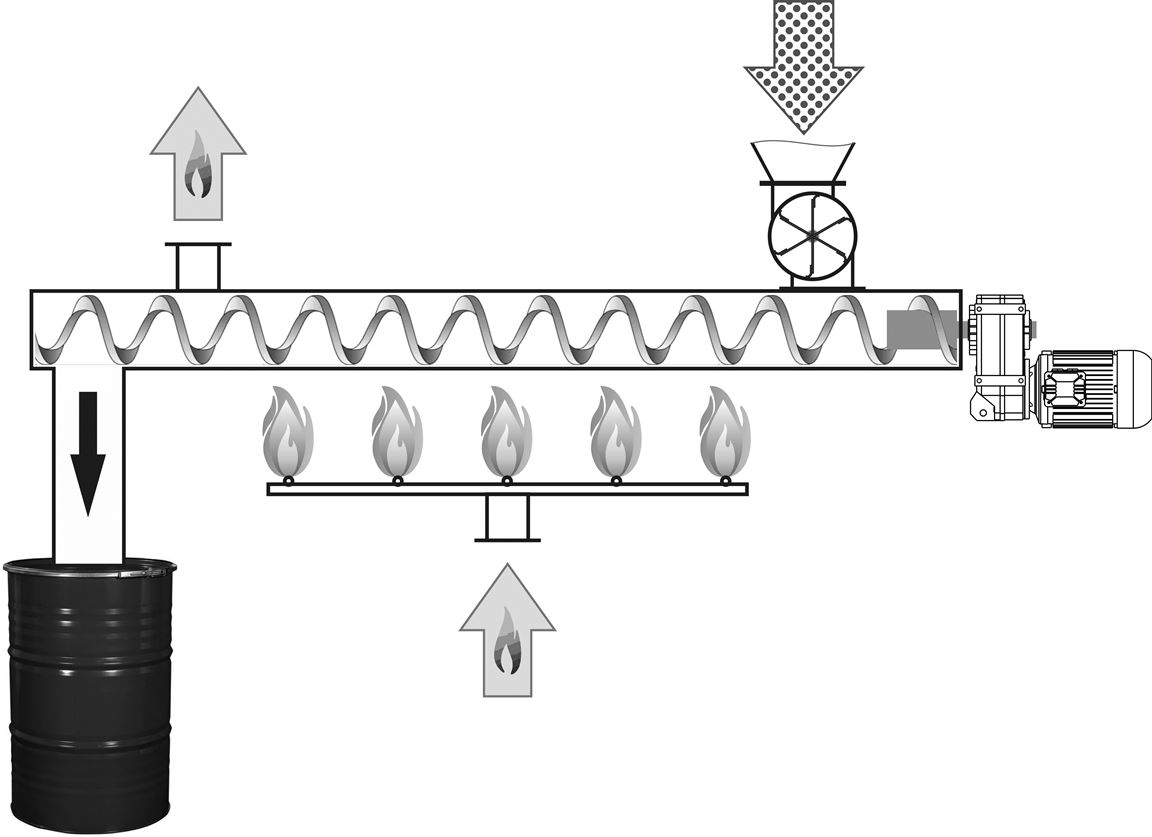

Spontaneous Combustion of Pellets

The second most frequent cause of nighttime fires is the spontaneous combustion of pellets at facilities operating on a single shift. In the absence of video surveillance, the usual suspects are arsonists pouring gasoline over packed products, as pellets cannot be ignited with a cigarette or even a burning stick due to their high density and thermal capacity. Such incidents actually occur when two circumstances converge. First, the production of pellets occurs under heavy wear of roller bearings and the die, when the pressing unit temperature exceeds 100°C (212°F) and pressing involves partial pyrolysis. Beyond 120°C (248°F), the pyrolysis process can already be exothermic, especially when processing old sawdust where fermentation processes by thermophilic microorganisms have started. The second condition is the improper or ineffective operation of the cooler. Due to clumps of sticking pellets, excessively hot weather, or improper operation, cooling occurs over too short a time and only on the pellet's surface. When placed in a big bag, it remains sufficiently hot, accumulating heat in mass up to carbonization and subsequent ignition. This phenomenon resembles fires in grain elevators when excessively moist raw material begins to heat up due to microbial activity, giving an initial heat, and further biochemical reactions between partially broken molecules themselves become heat sources. The process is fairly slow, potentially developing over 2 to 6 hours depending on warehouse temperature and product stacking density.

Personnel Getting Trapped in Equipment

Although it is mentioned in every operating manual, it is generally ignored, and nearly 90% of accidents occur due to unauthorized access to operating equipment. Staff quickly become accustomed to the moving conveyor chains and mixers in hoppers. Then, during cleaning or maintenance, an individual worker may find it inconvenient to cart sawdust or chips to an open storage area or designated spot. They may decide to open a conveyor or hopper lid and dump the material there. Sometimes the worker follows with the cart, or the edge of a large bag gets caught in the blades, which only fuels a sense of adventure as they try to retrieve the valuable packaging material from the grasp of the equipment. In summary, any access to equipment should only occur when it is completely de-energized and necessary lockout mechanisms are installed, regardless of experience, rank, or the severity of improper instructions from superiors.