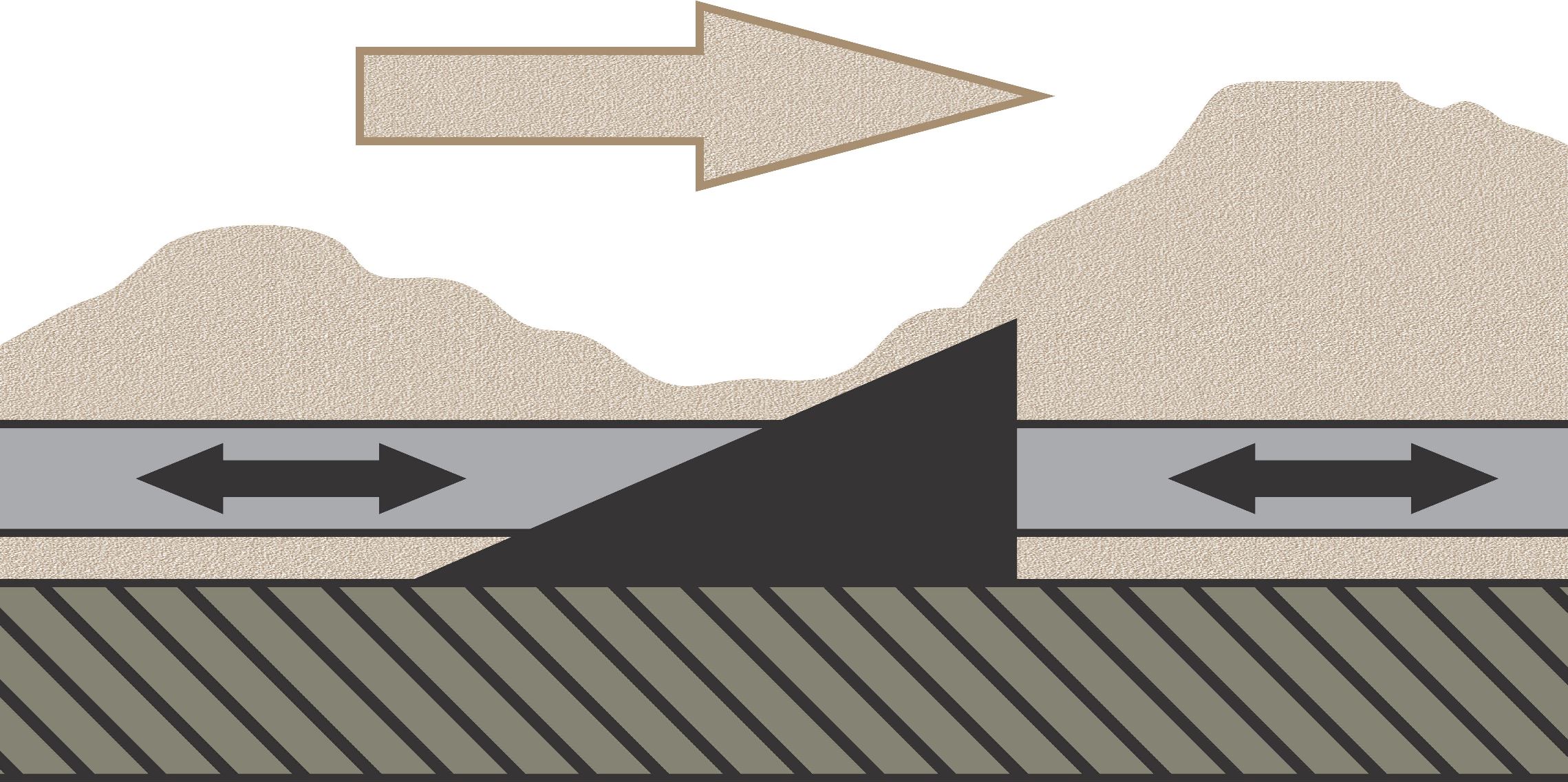

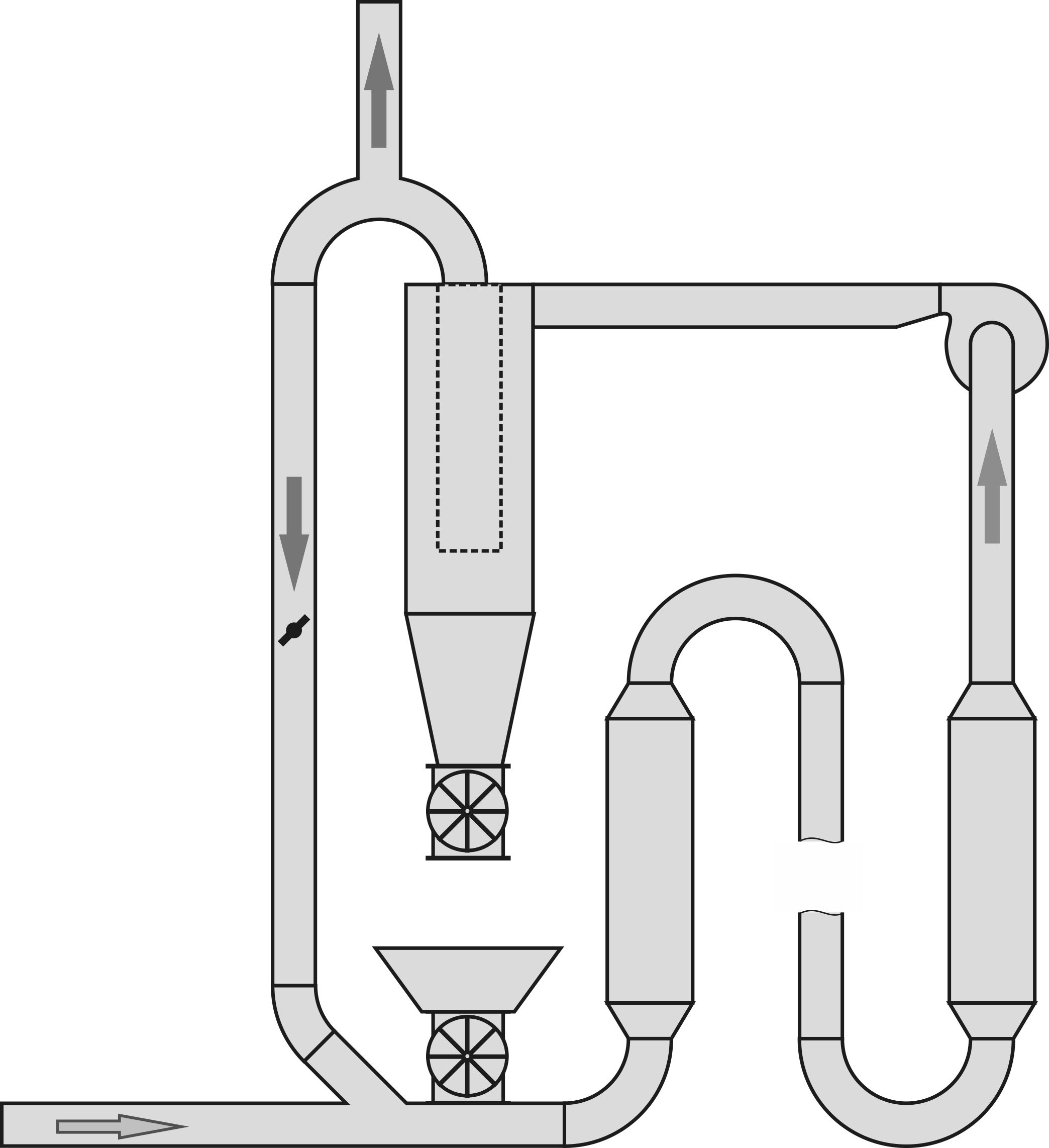

Recovery provides several advantages, especially for low-efficiency dryers like the aerodynamic dryer. Firstly, it partially saves thermal energy because the heat agent, which is already heated to 80-120°C (176-248°F), is reused instead of heating ambient air. Without recirculation, the maximum temperature of the air supplied is typically 180-200°C (356-392°F), while the output is 100-120°C (212-248°F). Exceeding this range can lead to rapid darkening of the wood or even ignition. It's easy to calculate that the efficiency of such a dryer is only about 30%, but with full recirculation, it can reach 70-90%. Secondly, the increased moisture content in the heat agent significantly speeds up the drying process because the superheated steam almost instantly transfers heat to incoming cold particles. This effect is successfully used in stationary wood and food product dryers to artificially increase humidity and save up to 30% of time. Thirdly, the constant dilution with flue gases, which already contain little oxygen, practically eliminates the risk of fire or explosion. Even for smoldering, minimal oxygen is needed, which is nearly depleted after several cycles of the heat agent.

Recovery provides several advantages, especially for low-efficiency dryers like the aerodynamic dryer. Firstly, it partially saves thermal energy because the heat agent, which is already heated to 80-120°C (176-248°F), is reused instead of heating ambient air. Without recirculation, the maximum temperature of the air supplied is typically 180-200°C (356-392°F), while the output is 100-120°C (212-248°F). Exceeding this range can lead to rapid darkening of the wood or even ignition. It's easy to calculate that the efficiency of such a dryer is only about 30%, but with full recirculation, it can reach 70-90%. Secondly, the increased moisture content in the heat agent significantly speeds up the drying process because the superheated steam almost instantly transfers heat to incoming cold particles. This effect is successfully used in stationary wood and food product dryers to artificially increase humidity and save up to 30% of time. Thirdly, the constant dilution with flue gases, which already contain little oxygen, practically eliminates the risk of fire or explosion. Even for smoldering, minimal oxygen is needed, which is nearly depleted after several cycles of the heat agent.

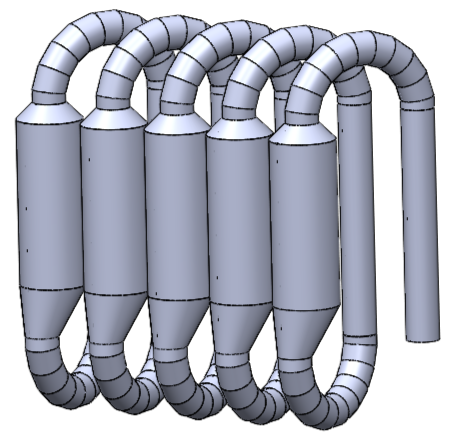

Remarkably, in this mode with the absence of oxygen, the temperature for initiating pyrolysis can be significantly increased. The darkened, dark-brown sawdust actually undergoes torrefaction. Impurities from relatively fresh sawdust allow the possibility of binding the material in briquetters or pellet mills, especially if it is fed directly for pressing without intermediate cooling and storage. The calorific value of such products increases sharply. For pellets, this offers the opportunity to transport energy over long distances. Briquettes made from torrefied sawdust are excellent material for further processing into charcoal, which becomes quite dense. This charcoal is not only inexpensive to transport but is also highly valued by consumers for use in grills.

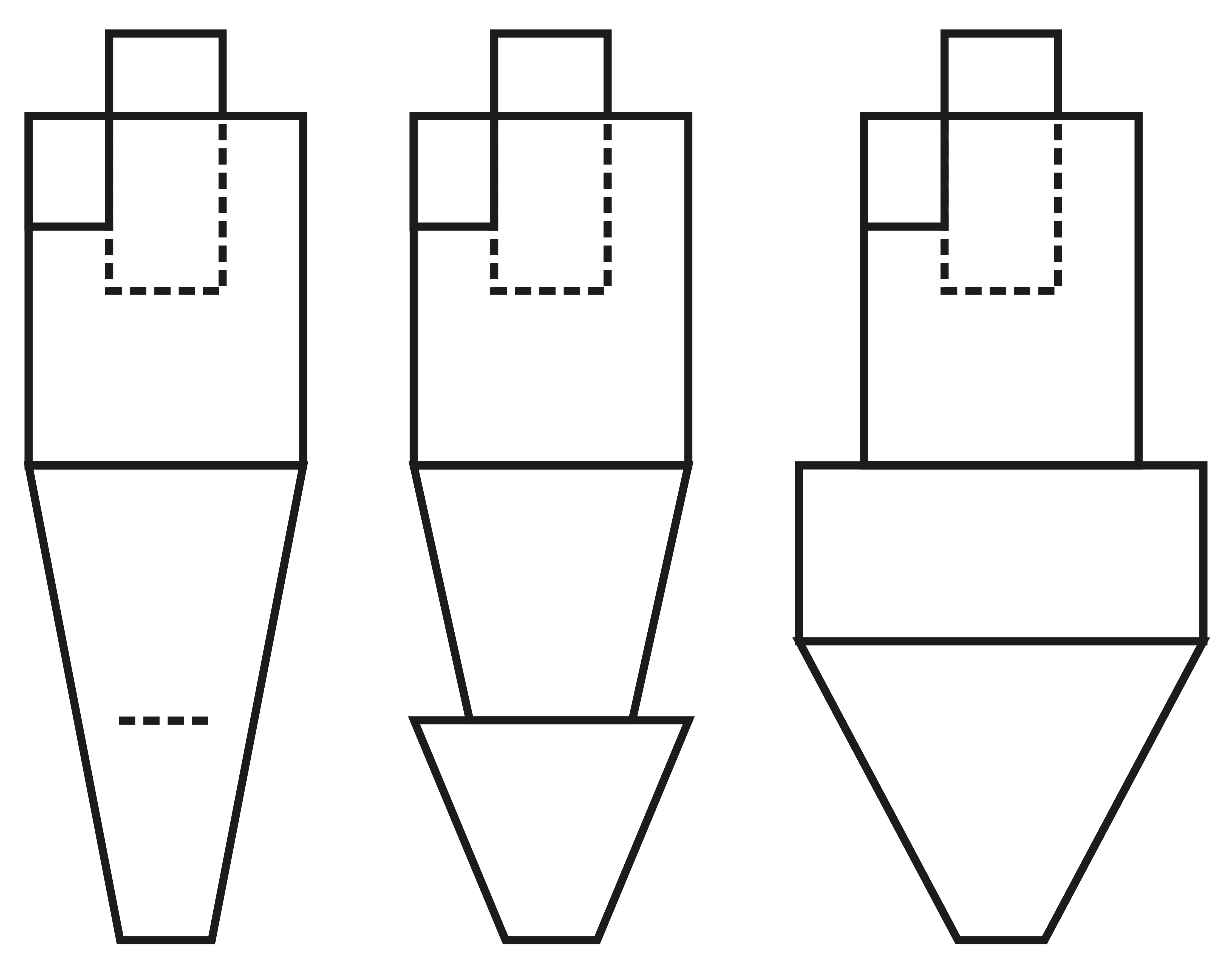

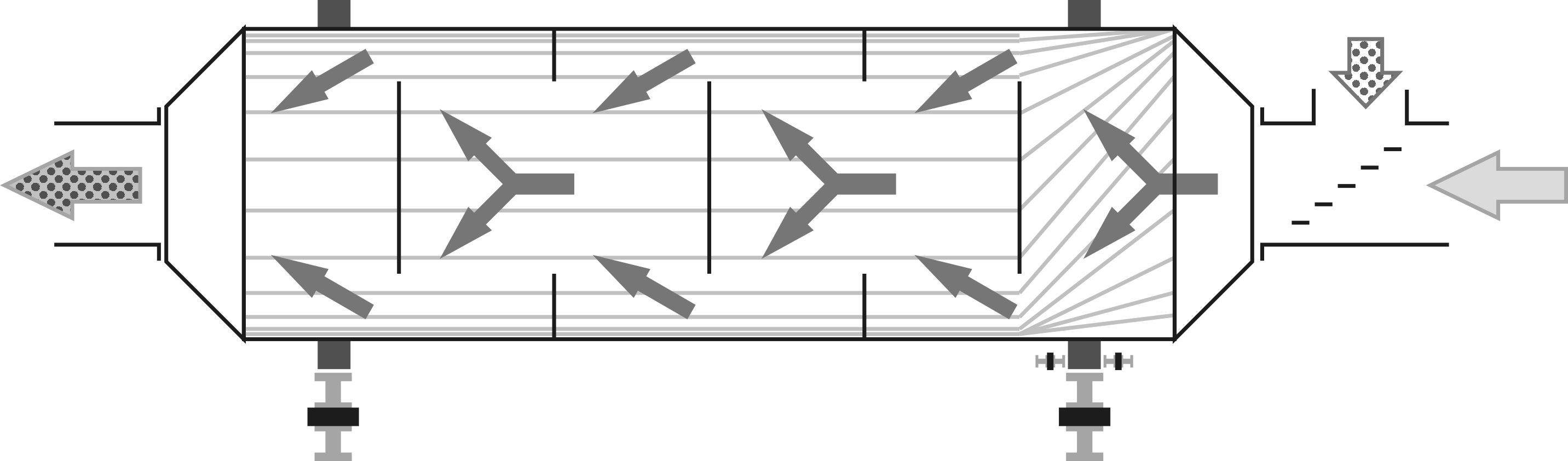

Although the example is given for the aerodynamic dryer, this method increases the efficiency and productivity of virtually any dryer that uses a mixture of air and flue gases as the heat agent. The danger of the method lies in incomplete recirculation and a simultaneously clogged cyclone, creating a situation where dry material suspension and sufficient oxygen for combustion and explosion are present at the dryer inlet in the high-temperature zone. Although the likelihood of such circumstances is low, automatic protection should be provided in the event of a sudden stop of the cyclone’s discharge valve, and the intake of fresh air into the dryer should be completely shut off. This also concerns the features of the heat generator setup since most models provide for mixing with fresh air in the last section of the lined casing, which is not adapted for mixing with contaminated sawdust emissions from the dryer.