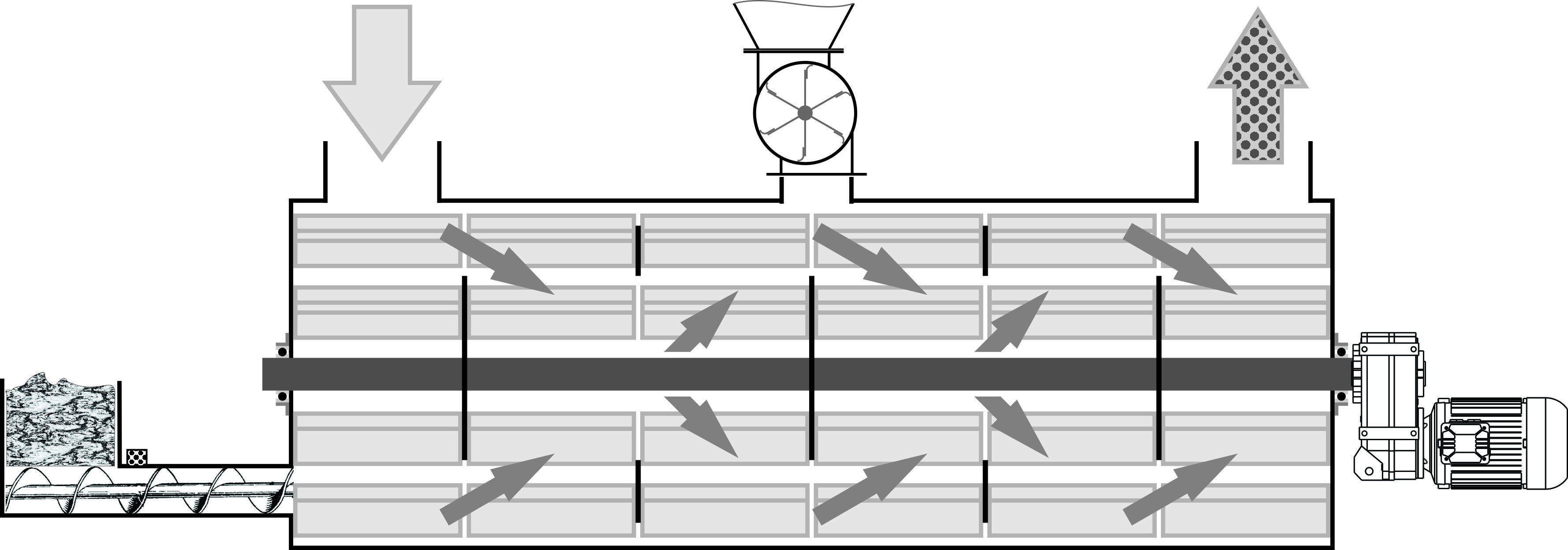

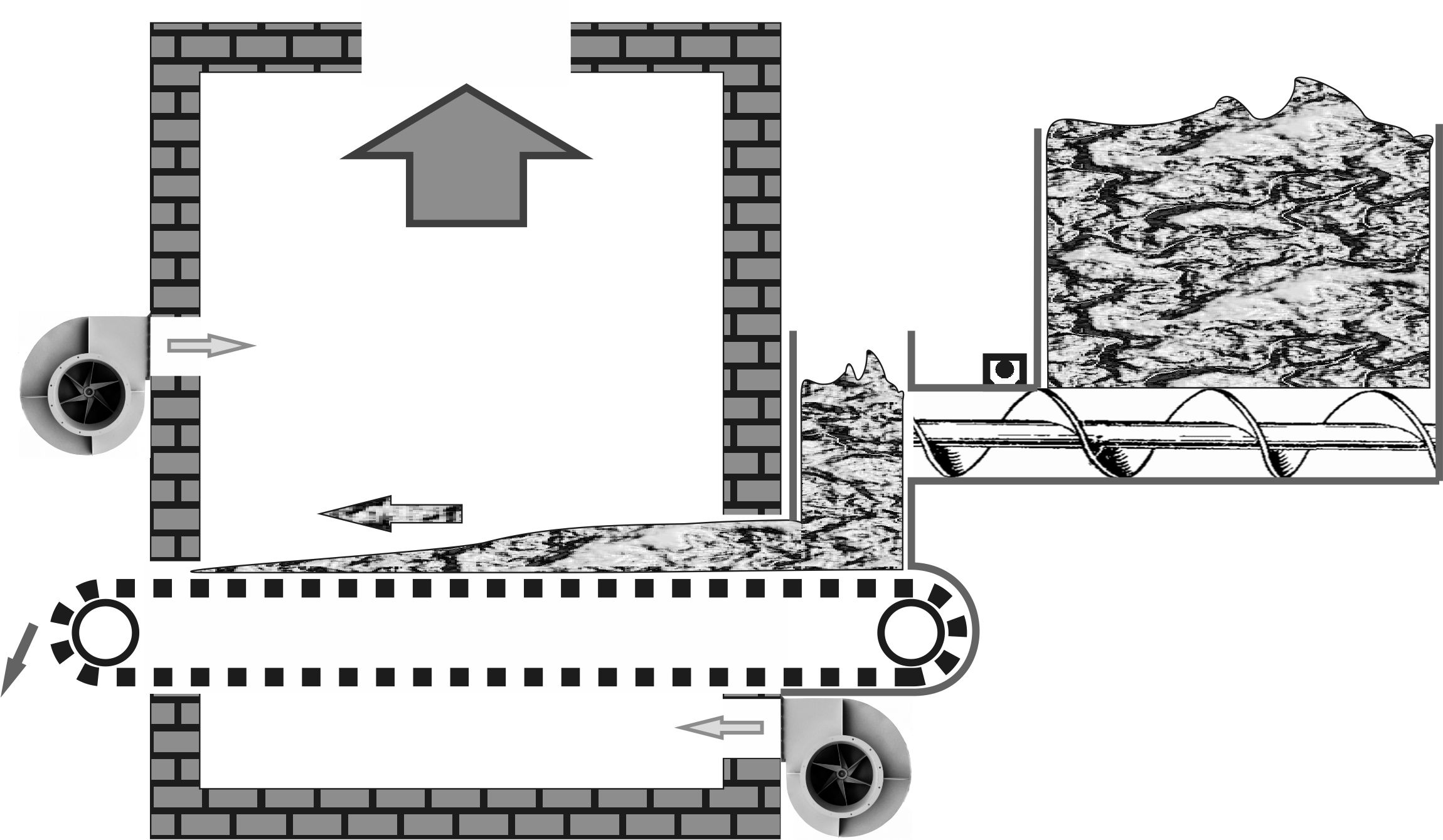

This is the most expensive and versatile option. The design is similar to a chain conveyor, but instead of vertical scrapers, horizontal plates with openings, known as grates, are attached. Depending on the thickness of the fuel layer, its moisture, and particle size, either a pyrolytic or direct type of combustion may dominate. Such heat generators perform excellently with very dirty raw materials that have a high ash content, such as bark, secondary processed wood, or fuel with a low ash melting point.

The combustion of sunflower husks, pellets made from them, straw, and other agricultural waste usually occurs with a minimal layer thickness to prevent local ash accumulation with smoldering embers. Active grate ventilation cools them, preventing temperatures from exceeding the critical 800°C (1472°F) that can cause the vitrification of solid combustion residues.

The combustion of sunflower husks, pellets made from them, straw, and other agricultural waste usually occurs with a minimal layer thickness to prevent local ash accumulation with smoldering embers. Active grate ventilation cools them, preventing temperatures from exceeding the critical 800°C (1472°F) that can cause the vitrification of solid combustion residues.

The grate movement speed for raw chunk-type fuels is selected based on the fuel's particle size and can be adjusted with changes in the unit's load. It is important that most of the grates are covered with fuel to ensure even heating of the internal space; otherwise, sharp temperature differences from end to end of the furnace may damage the refractory lining. On average, moist wood chars at a rate of 1 mm per minute. Therefore, a 10 mm (0.4 inch) thick chip will typically burn in 10 minutes. Active air blowing may slightly accelerate the process, and a dense layer can prolong it, leading to unburned charcoal forming in the ash collector. The layer of material between smoldering charcoal and the just decomposing wood has limited heat conductivity, based on a temperature gradient from 100°C (212°F) at the wet wood side to the chemical activity acquisition of charcoal at 800°C (1472°F). Too intense ventilation can lead to heat loss and extinguishment. The grate movement speed is selected for maximum complete combustion, considering the median particle size of the top 20% largest screened samples of fuel. Sometimes, for highly heterogeneous particle size raw materials, the layer is deliberately increased with slowed movement to achieve uniform and complete fuel combustion.

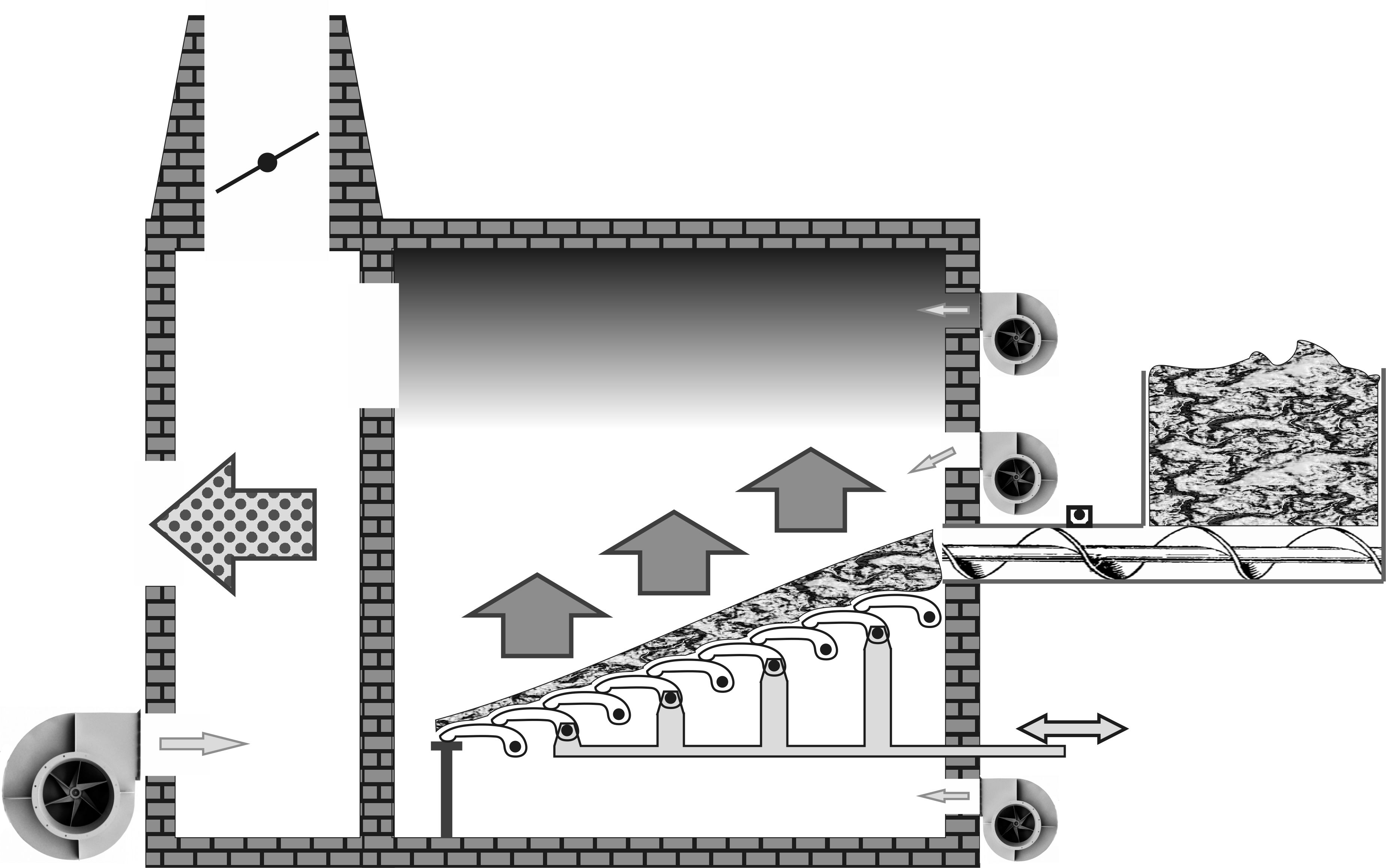

Achieving a thin fuel layer with a conveyor design by only adjusting the damper height can be difficult when large inclusions are present among the chips, or the fuel tends to clump due to a fibrous structure like bark or unrefined peat. In such cases, the advantages of a stepped furnace are combined with grate mobility, with every second grate moving in a staggered arrangement. The more intense the movement under the fuel, the thinner the burning mirror layer becomes. As you can notice, the plates are arranged at a much gentler slope than regular steps, and while mutual friction increases wear, it effectively manages mutual cleaning from ash accumulations.

Achieving a thin fuel layer with a conveyor design by only adjusting the damper height can be difficult when large inclusions are present among the chips, or the fuel tends to clump due to a fibrous structure like bark or unrefined peat. In such cases, the advantages of a stepped furnace are combined with grate mobility, with every second grate moving in a staggered arrangement. The more intense the movement under the fuel, the thinner the burning mirror layer becomes. As you can notice, the plates are arranged at a much gentler slope than regular steps, and while mutual friction increases wear, it effectively manages mutual cleaning from ash accumulations.