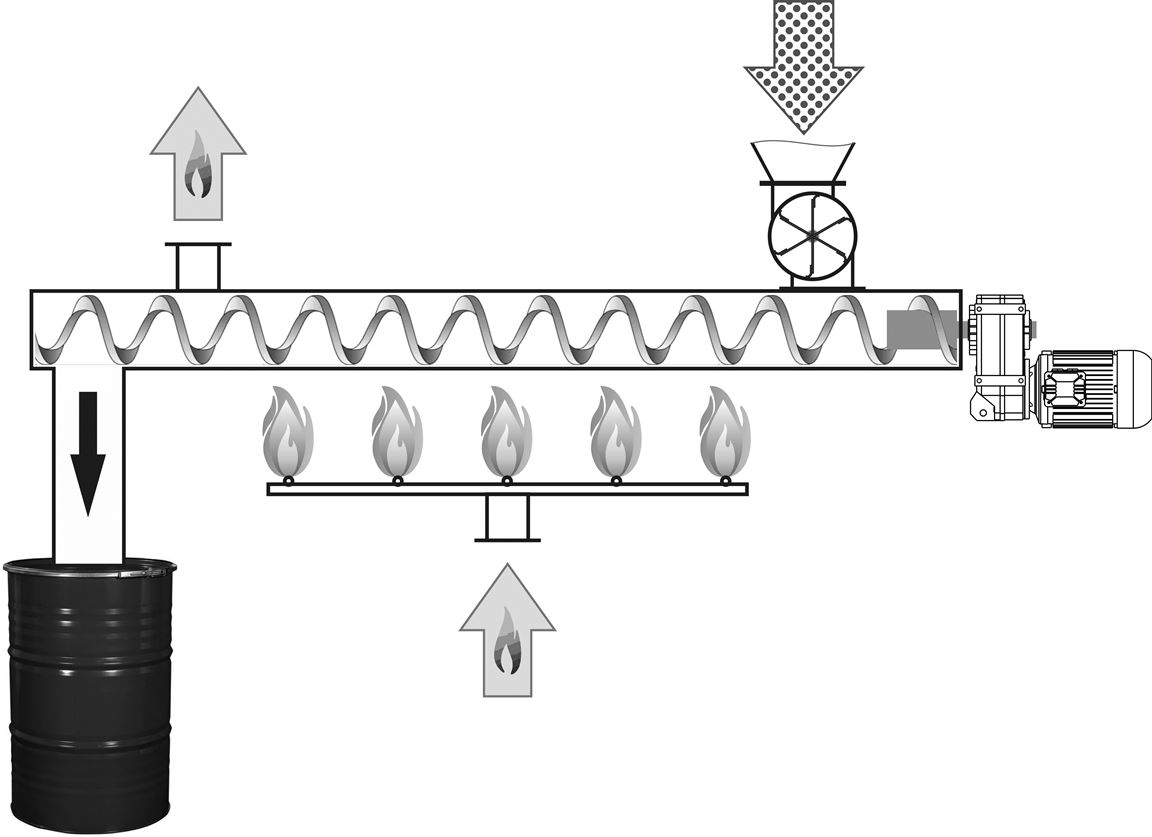

For pelletizing, the moisture content of the raw material needs to be quite low, about 8-12% for biofuel purposes and up to 25% when pelletizing bedding manure. The initial moisture content of biomass is typically much higher. To dry it, hot air is used, specifically a thermal agent, which is a mixture of furnace gases and atmospheric air. Sometimes heat is transferred to the dryer via hot water or steam, but the basic design of the heat generator differs only by incorporating a heat exchanger in such cases. A portion of the raw material is usually used as a source of cheap fuel, simplifying production facility logistics and eliminating costly connections to gas pipelines.

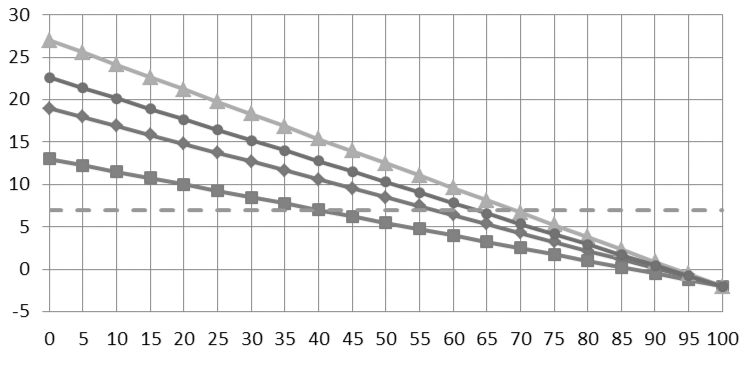

The peculiarity of burning wet fuel is that drying and pyrolysis processes occur simultaneously, and the resulting gases are what actually burn. Since a significant amount of heat is used to evaporate ballast moisture, it becomes much harder to ensure stable and efficient combustion as the wood moisture increases. Essentially, the fuel's calorific value decreases, and if not enough heat is returned for drying and pyrolysis of fresh chip portions, combustion stops. Most equipment can burn fuel with a calorific value of at least 7 MJ/kg. The graph shows the correlation between calorific value and moisture content of various fuel types in ascending order: manure, wood, sludge, and high-ash coal.

Therefore, the minimum allowable moisture content of fuel is calculated individually depending on its type. As seen in the graph, the moisture limit for wood is 55%, while for manure, it is only 40%.

Therefore, the minimum allowable moisture content of fuel is calculated individually depending on its type. As seen in the graph, the moisture limit for wood is 55%, while for manure, it is only 40%.

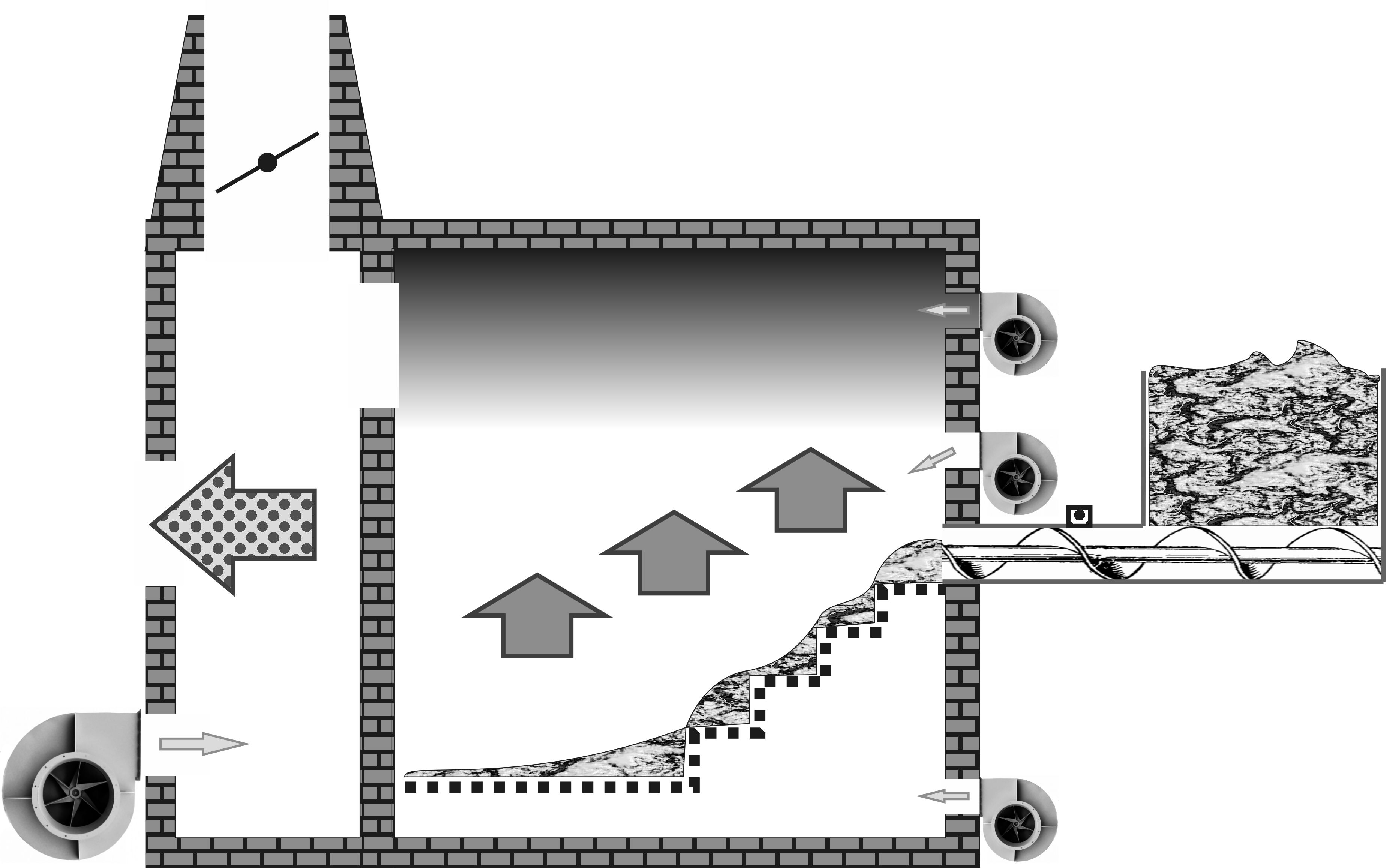

With low power and furnace volume of the heat generator, drying and pyrolysis occur in nearly the same spot, and optimizing forcing and preheating provides a minimal contribution to the device's efficiency. With power above 500 kW, the grate area and furnace shape might affect the quality of gas afterburning, the activity, and the uniformity of fuel drying.

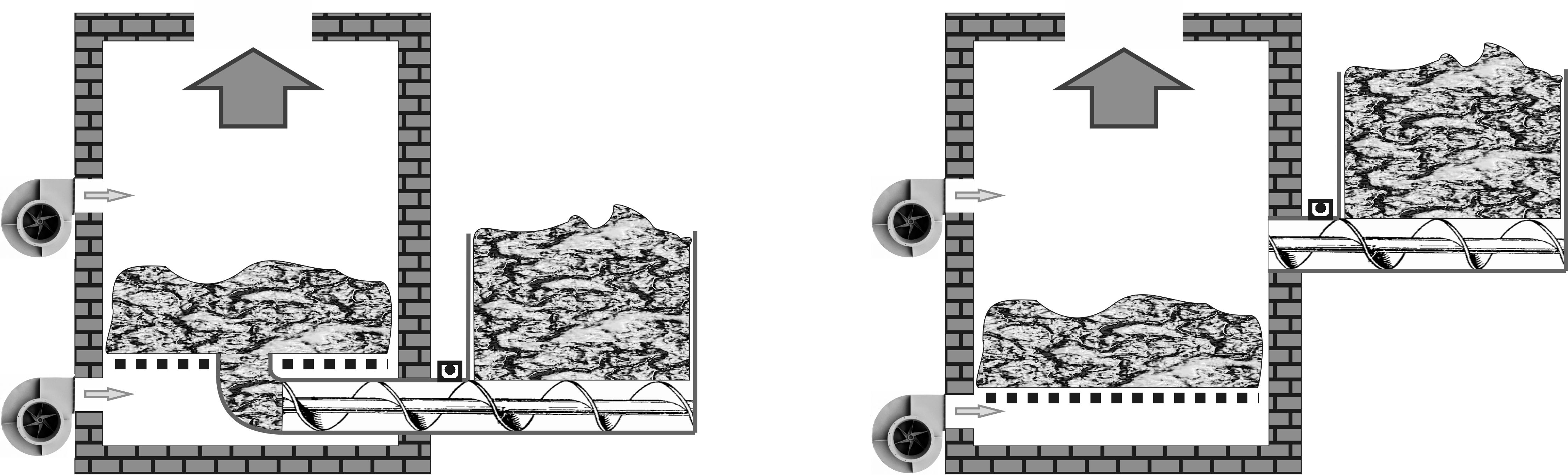

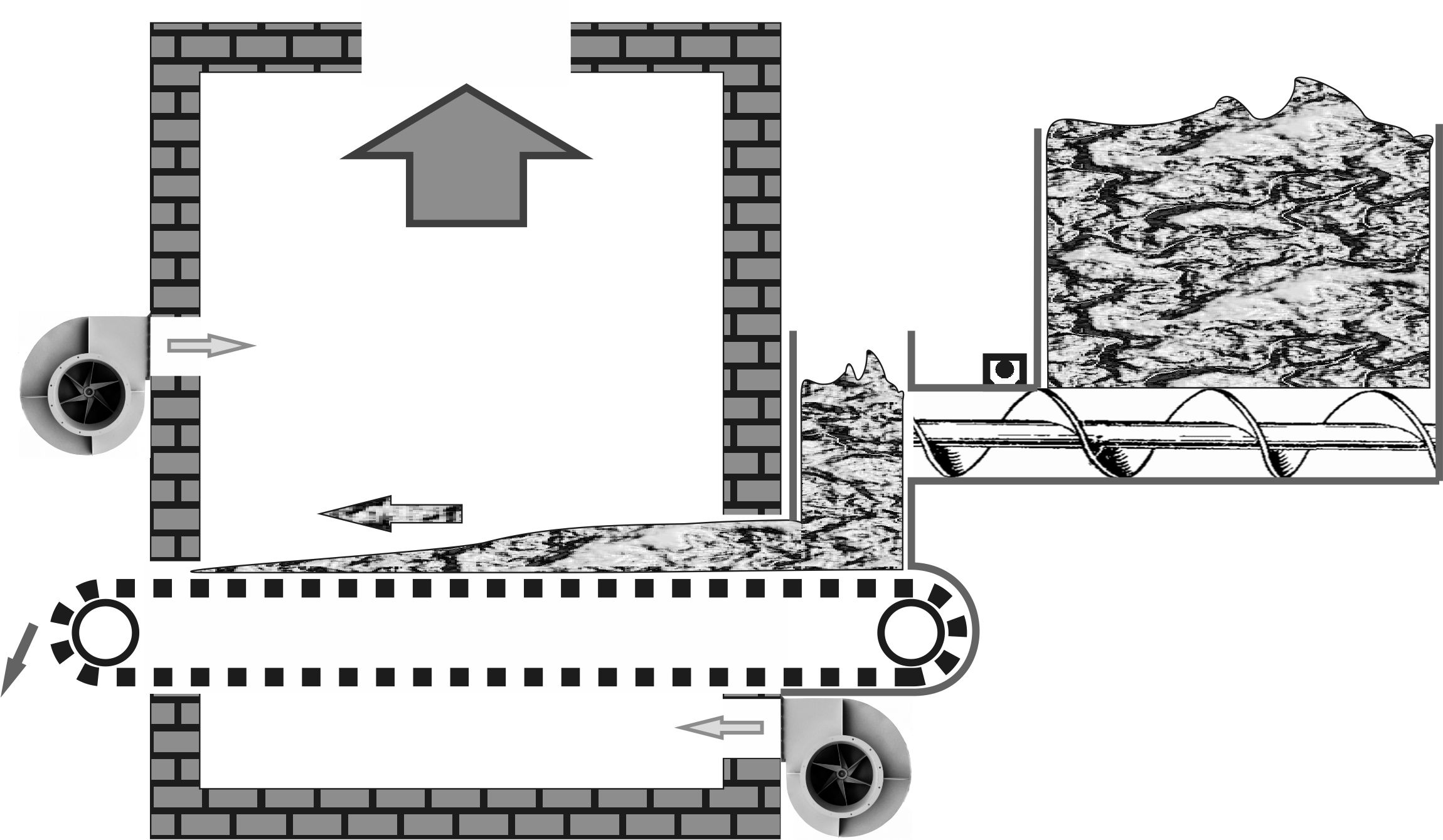

The designs of all furnace devices for burning wet fuel can be divided into three types: