Brief Answer: You can extend the lifespan of the die and rollers by cleaning the material from sand and metal impurities, correctly adjusting gaps, and timely restoring the countersink of the holes.

Why This is Important

The die and rollers are the most stressed and expensive consumables in the pellet mill. Their wear directly affects the quality and cost of the pellets.

Main Factors of Wear

- Abrasive Inclusions — sand, dirt, and metal particles accelerate the degradation of surfaces.

- Incorrect Moisture Content of Material — overly dry material creates increased friction, up to clogging the die and causing it to break from overload.

- Play in Roller Bearings — jamming of overheated bearings can smooth and damage the die.

- Uneven Track Wear of the Die — installing new rollers on an old, uneven die causes accelerated wear of both parts.

Quick Answer: The main wear factors are abrasive inclusions in the material, incorrect moisture content, play in roller bearings, and uneven wear of the die track.

How to Extend the Lifespan

- Use magnetic and vibratory separators to clean the material.

- Maintain moisture at 8-12%.

- Regularly lubricate the bearings and rollers.

- Timely adjust the tapered bearings of the rollers.

- Align the die track with the restoration of hole countersinks before changing the rollers.

- Do not use abrasive mixtures to polish die channels.

Quick Answer: Maintain moisture between 8-12%. On the lower end, pellets come out hard and unglued, on the upper end, they are less durable but become optimal in strength after cooling, reducing wear.

How to Avoid Premature Failure

Keep a maintenance log of the pellet mill: during the shift, record not only the quantity of product made but also log productivity, pellet quality, and current load on the main drive. These parameters will help identify when it's time to move the rollers closer to the die and timely increase moisture to achieve maximum quality and performance.

Expert Advice

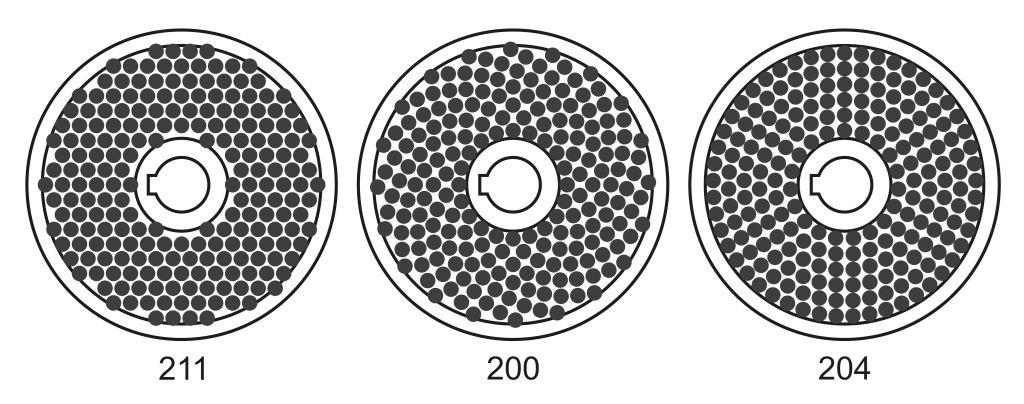

Grinding the die with abrasive mixtures, although a popular technique, sharply reduces the lifespan of the die and rollers. It's much more beneficial to acquire a higher quality die with the right effective hole length and entrance angle of the countersink.

Quick Answer: Grinding with abrasive mixtures does not extend lifespan but reduces it. It’s better to choose a quality die with correct geometry.

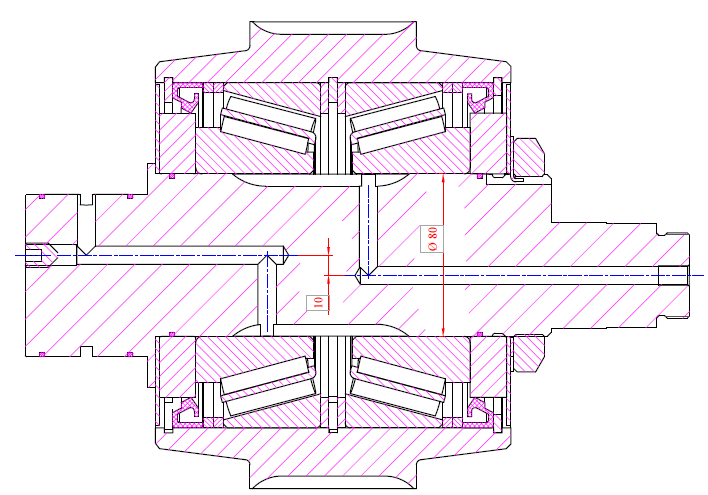

Installation and Maintenance

When installing the die on a cone, it's important to evenly tighten the bolts with a torque wrench and check for runout with an indicator. For cylindrical seating, the die must fit snugly in the blank flange. Improper seating leads to bolt breakage or even cracks from the keyway slot.

Quick Answer: Follow correct die seating — this protects both the die and rollers from damage.