Brief Answer: The die is selected based on the biochemical composition of the raw material, while the rollers are chosen according to the abrasiveness of the material.

Problem Symptoms

- Pellets are not forming.

- The die gets clogged.

- The shells on the rollers wear out quickly.

Main Causes

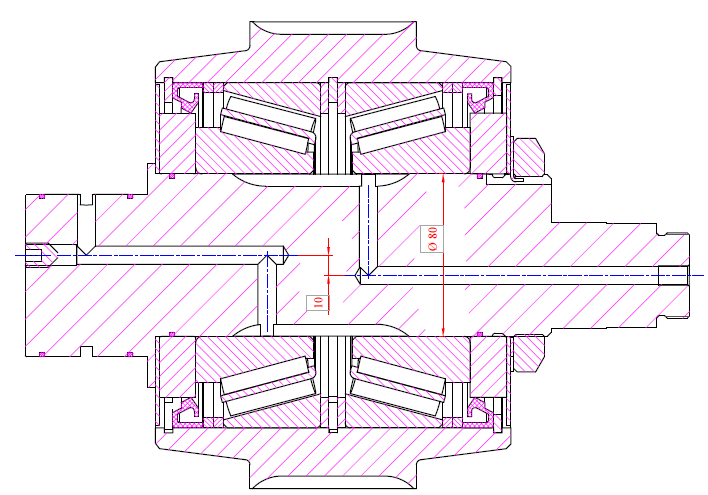

- The effective length of the die hole is too short — insufficient compression force and retention time for material in the die holes.

- The effective length of the die hole is too long — the material overheats and gets stuck in the holes.

- The teeth on the roller shell are too small — fast wear on abrasive material.

Problem Solution

- Check the actual working length of the die holes; it may differ from what is marked on the die.

- Use a die with a longer channel length during winter when the material is cold.

- Use roller shells with drilled surfaces instead of toothed ones.

How to Avoid Repetition

Carefully check the geometry of the die holes and the surface of the shells before installation. Plan the purchase of consumables according to the production plan for various types of materials.

Expert Advice

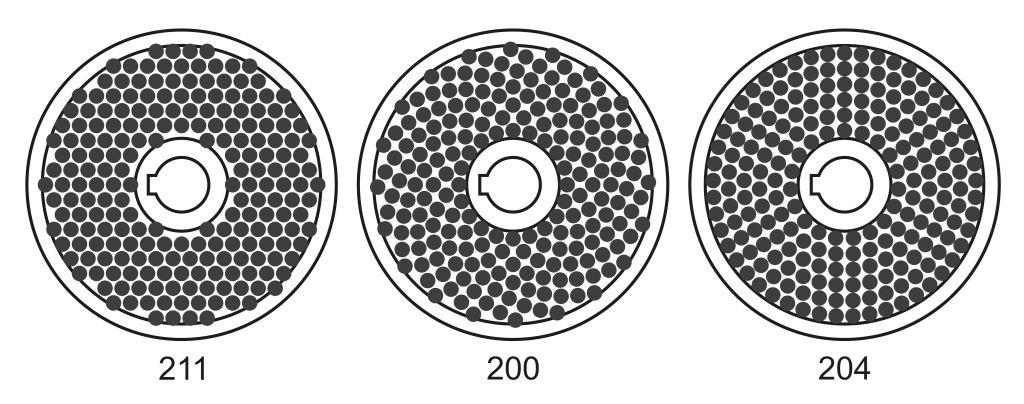

The effective length of the die holes affects both the retention time of the material under pressure and the pressure magnitude. If the material is soft and the pellet diameter is small, the radial load on the die will be minimal, allowing you to reduce the total thickness of the die to save on consumables. Read more in the article "Working Length of the Die and its Shape"

If the material is hard and requires more pressing force, and reducing the effective length of the hole worsens pellet quality, choose a die and roller shells with a narrower track to reduce the load on the pellet mill. Read more in the article "Sample Calculations and Practice"

The corrugated surface of the shell is universal for all types of materials. The most popular tooth width and groove are about 2.5mm (0.1 inches), but for more abrasive materials, roller shells with a tooth width of 3.5mm (0.14 inches) are used. For processing dirty wood materials, peat, or making organo-mineral fertilizers, shells with drilled holes on the track surface are used. Read more in the article "Influence of the Surface Form of the Track on the Shell"