Hydraulic stoker storage allows for temporary storage and efficient supply of large volumes of bulk raw material, often used as an intermediate storage between the primary crushing area and the drying complex.  The use of hydraulics enables the movement of multi-ton piles with minimal energy expenditure. The first drawback of this storage is that wheeled equipment cannot access it, requiring additional conveyors for unloading or the construction of quite a tall and expensive ramp. The second technical drawback is the extremely uneven supply of raw material, which prevents direct feed into units. A buffer hopper with a feeder, which will be discussed later, needs to be installed.

The use of hydraulics enables the movement of multi-ton piles with minimal energy expenditure. The first drawback of this storage is that wheeled equipment cannot access it, requiring additional conveyors for unloading or the construction of quite a tall and expensive ramp. The second technical drawback is the extremely uneven supply of raw material, which prevents direct feed into units. A buffer hopper with a feeder, which will be discussed later, needs to be installed.

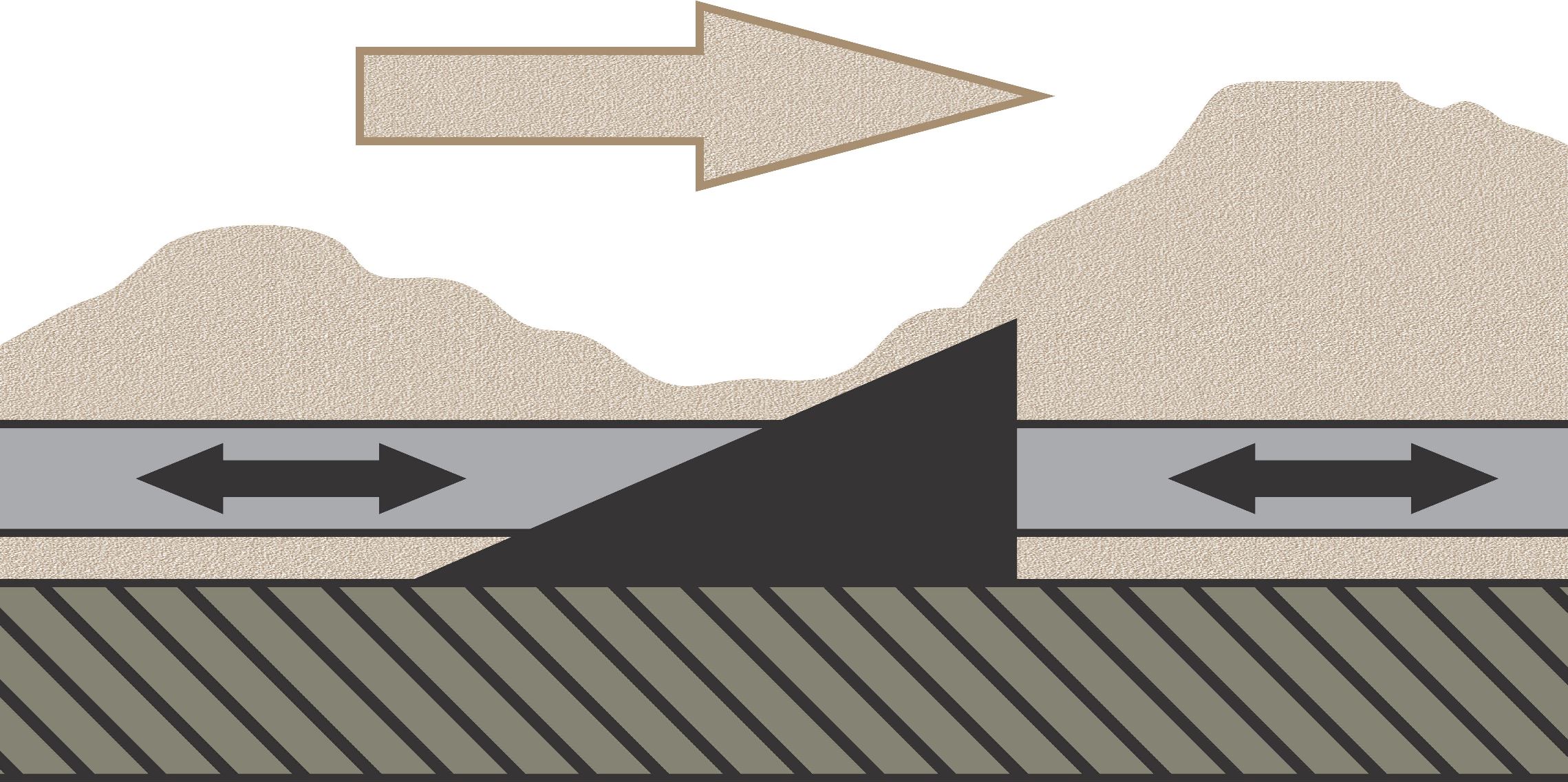

Stoker storages are justified for useful volumes from 100 to 400 m³ (3500 to 14000 ft³). The design of stokers features welded triangular scrapers, which push the raw material onto the conveyor with vertical walls during the working stroke and dig under the pile with inclined walls with much less effort during the return stroke. Most of these devices operate without overloading the drives with a layer of raw material up to 4 meters (13 feet) high. In the illustration, by the way, a less optimal arrangement is shown where the hydraulic cylinders are placed on the discharge conveyor side. This results in the greatest load on the stokers being in tension during the working stroke and more effortless compression during the return. Such an arrangement is either unreliable or significantly more expensive due to the need for much thicker metal. It is much more beneficial to position the hydraulic cylinders and conveyors on opposite sides of the raw material, which has been proven in the harsh operating conditions of Siberia.

Stoker storages are justified for useful volumes from 100 to 400 m³ (3500 to 14000 ft³). The design of stokers features welded triangular scrapers, which push the raw material onto the conveyor with vertical walls during the working stroke and dig under the pile with inclined walls with much less effort during the return stroke. Most of these devices operate without overloading the drives with a layer of raw material up to 4 meters (13 feet) high. In the illustration, by the way, a less optimal arrangement is shown where the hydraulic cylinders are placed on the discharge conveyor side. This results in the greatest load on the stokers being in tension during the working stroke and more effortless compression during the return. Such an arrangement is either unreliable or significantly more expensive due to the need for much thicker metal. It is much more beneficial to position the hydraulic cylinders and conveyors on opposite sides of the raw material, which has been proven in the harsh operating conditions of Siberia.

The foundation on which such storage is placed is made of a steel structure or concrete. The smallest version, with a capacity of 80-100 m³ (2800-3500 ft³), can be placed in a 40-foot container, resulting in significant cost savings. It is advisable to immediately fix a heating cable and insulation to the underside of the floor to prevent the scrapers from freezing when precipitation falls in winter. When constructing concrete structures, it is essential to provide for the possibility of heating, especially in regions with frequent and long-lasting frosts. Considering the inability to repair an electric heating cable, it is preferable to opt for an ordinary plastic pipe attached to the reinforcement before pouring concrete, connected to a small boiler filled with antifreeze through a circulation pump.