Commissioning specialists must prepare an action plan in advance with specific parameters they aim to achieve on the first start. They should also include algorithms for achieving these results. Adjustments of temperatures and electrical loads should be described in simple and understandable terms. Such a plan should be printed in several copies and distributed to the employees undergoing training. It is important to decide in advance within the team who is responsible for each section. While the equipment vendor representatives are launching the system, the local staff can still move around various sections to learn about the duties and responsibilities of adjacent roles. However, from the second launch onward, it is preferable for the local staff to press the control panel buttons following the technologists' guidance, as this will speed up the learning process. The staff should also be given the right to stop any machine with the emergency button if they hear any unusual noise like squeaks or bangs. Workers need to become used to managing everything themselves, and in a critical situation, this habit could save equipment and even lives. This will also allow for immediate practice of the procedures to resume work or address issues with adjacent machines.

If the plant is started at above-freezing temperatures, it is advisable to chip wood in advance and fill the receiving hoppers with sawdust, placing logs on the feed tables. During frosty conditions, hoppers with fresh chips should not be left out in the open air for long, and sawdust crushed in the hammer mill must be fed into the dryer within 10-15 minutes, as it is very prone to freezing solid, especially in less active storage areas.

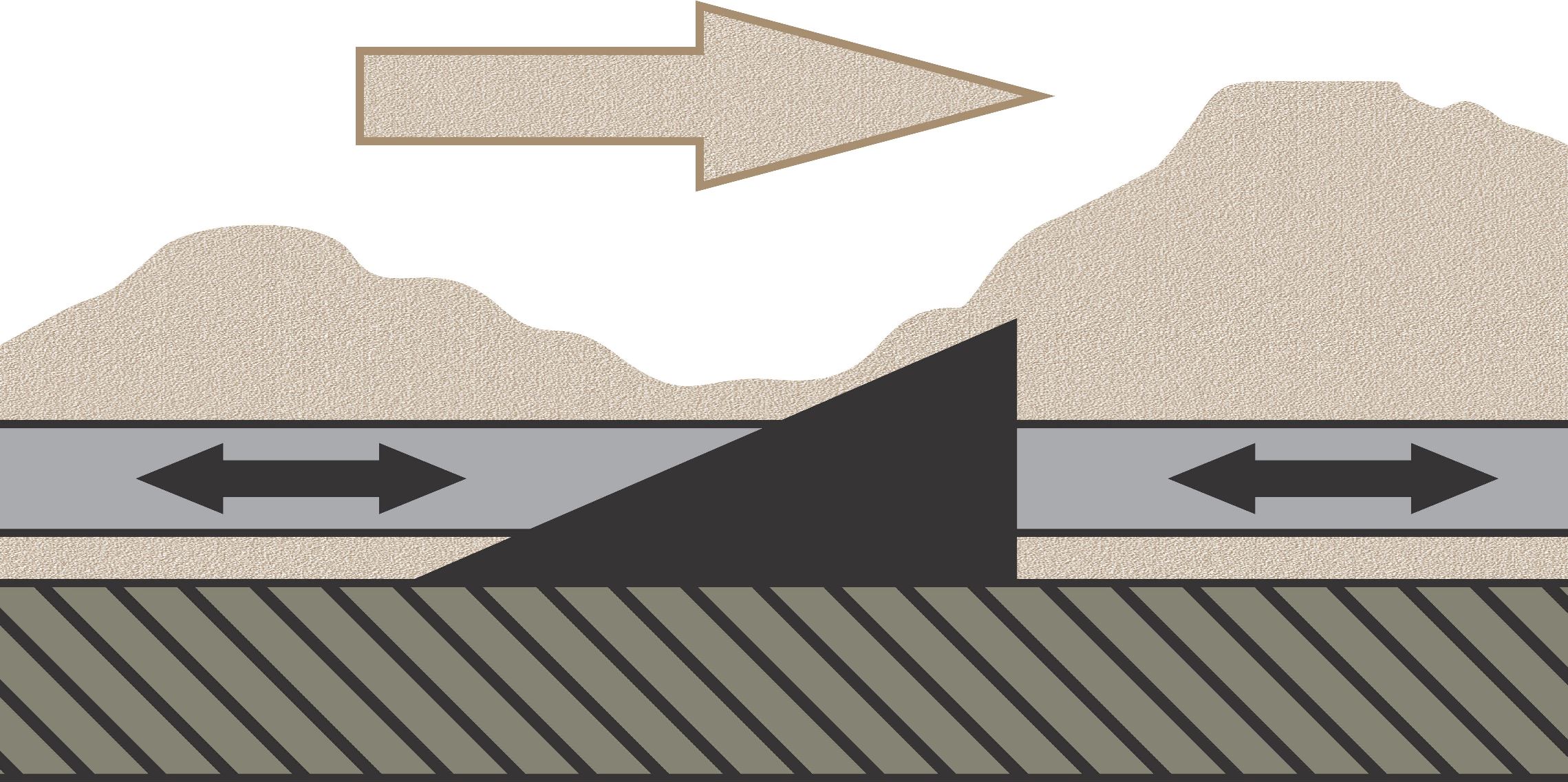

The startup usually begins with the heat generator, which is pre-fired with small portions of fuel to carefully dry and temper the lining. Before lighting up, ensure that all drives are functioning properly, all dampers are adjusted to the desired positions, and all sensors are showing readiness brightly. After lighting up, pay attention to the draft sensor in the burner, which shows the ability to create a draft through the firing tube. If the draft is less than 50 Pa, the chimney may be too short or narrow, which could lead to room smoke and fire during an emergency shutdown of the heat generator. A chimney that is too wide could also reduce draft, as the slow movement of flue gases leads to rapid cooling. The optimal flue gas velocity in the chimney is 1.5-2.5 m/s (5-8 ft/s), which should be considered when designing chimneys.

All machines in the production chain up to the feed bin of the heat generator and the raw material storage for the dryer can typically be stopped at any time. They are the most hazardous, as logs may fall from conveyors in the raw material preparation area, ice can form on platforms and stairs, and the equipment supplying raw materials has blind spots. Therefore, before starting, ensure the functionality and sufficiency of emergency stop buttons. It is better to stop the chipper one extra time than be afraid to check it out later.

Monitoring the rotation of the drying drum or rotor, as well as the transporter with a hopper feeding the dryer, should be clearly visualized using flags or lights so that an unexpected stop is visible from any point in the workshop. If the dryer stops, all possible measures should be taken to lower the temperature at the drum entrance: open the hatch in front of the drum to allow cold air in, turn off the blower, and switch the heat generator to the firing mode. The actions' composition and sequence should be practiced in advance, or else in a critical situation, faced with the threat of fire, the staff may become confused.