Auger Separator

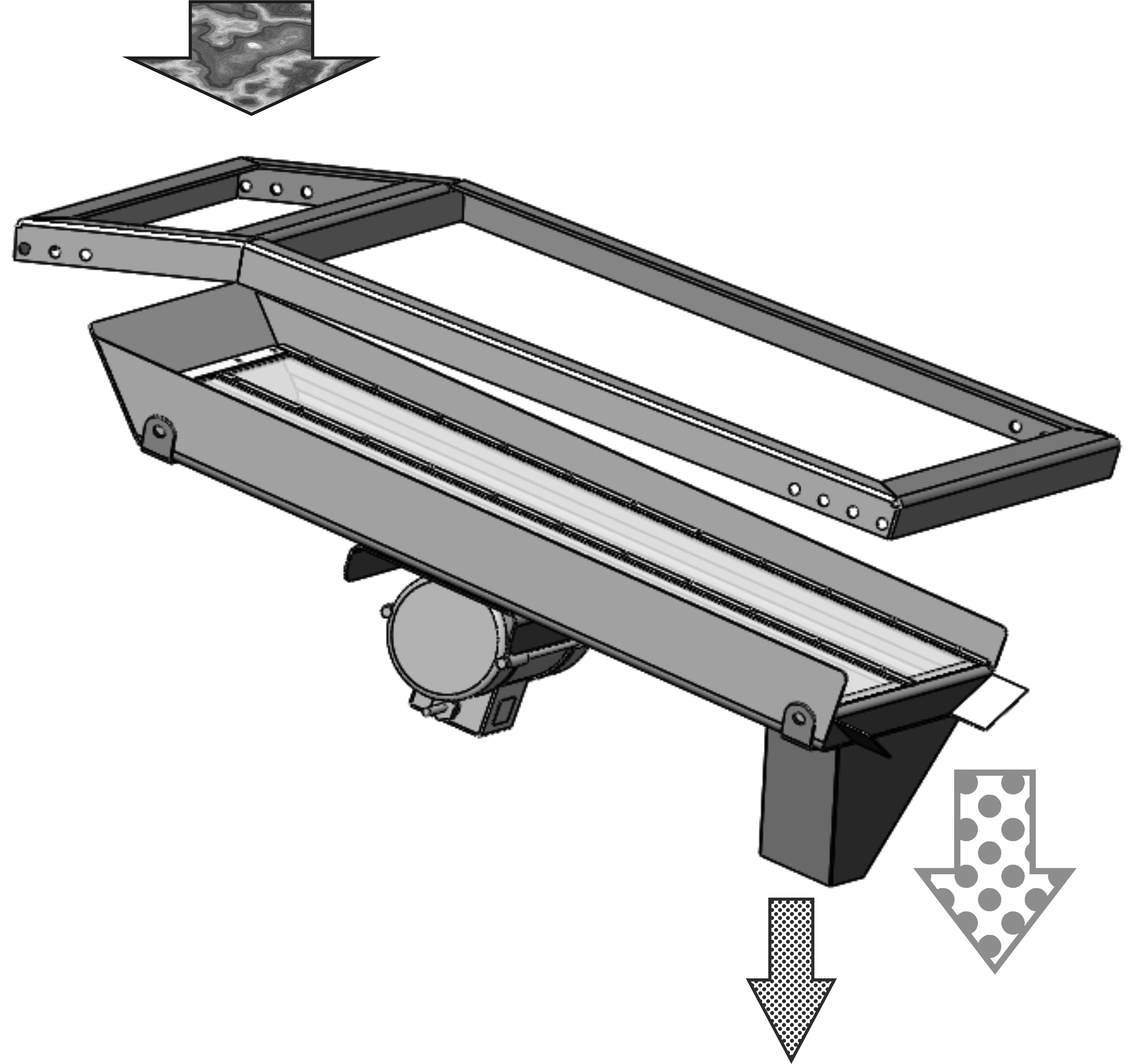

Often the initial biomass arrives in a semi-liquid or pasty state. Sticky manure from cage contents is removed by belt conveyors equipped with a cleaning scraper at the discharge side. During the washing of the manure, the flow formed has a dry matter content of only 3-5%. Brewery spent grain goes through a pressing stage at the plant, but after transportation, the liquid content increases again due to ongoing fermentation. In this form, the material can also be dried by spraying it in drying columns against the ascending flow of warm air, but the heat costs become tremendous. There is a separate issue with liquid leakage during the transportation of raw materials, as well as sticking in different equipment. Thus, before drying, the aim is to dehydrate the mass as much as possible, and the simplest and most cost-effective method is mechanical pressing.

The design of the separator is very similar to a typical auger juicer. Inside the auger casing, there is a screen through which the liquid part drains, and at the outlet, there is a device to regulate the pressing pressure. The pressure is adjusted by blocking the outlet, retaining the raw material inside to create more friction and pressing force. The blockage is seldom set for rigid adjustment since the self-compaction of the biomass leads to frequent clogging of the auger, which requires labor-intensive cleaning. For brewery spent grain or similar raw materials with relatively stable fractions, the blockage occurs using a simple spring-loaded plate, where the spring is placed on a stud coaxially with the auger or directly on the auger shaft, and its pre-tension is adjusted with a nut. For manure, which contains lumps of varying fractions and moisture, it is preferable to block the outlet with dampers, the closing force of which is regulated by a special lever with weights. This device can open widely when a large amount of thick material is suddenly fed, keeping the load on the auger drive within reasonable limits.

The design of the separator is very similar to a typical auger juicer. Inside the auger casing, there is a screen through which the liquid part drains, and at the outlet, there is a device to regulate the pressing pressure. The pressure is adjusted by blocking the outlet, retaining the raw material inside to create more friction and pressing force. The blockage is seldom set for rigid adjustment since the self-compaction of the biomass leads to frequent clogging of the auger, which requires labor-intensive cleaning. For brewery spent grain or similar raw materials with relatively stable fractions, the blockage occurs using a simple spring-loaded plate, where the spring is placed on a stud coaxially with the auger or directly on the auger shaft, and its pre-tension is adjusted with a nut. For manure, which contains lumps of varying fractions and moisture, it is preferable to block the outlet with dampers, the closing force of which is regulated by a special lever with weights. This device can open widely when a large amount of thick material is suddenly fed, keeping the load on the auger drive within reasonable limits.

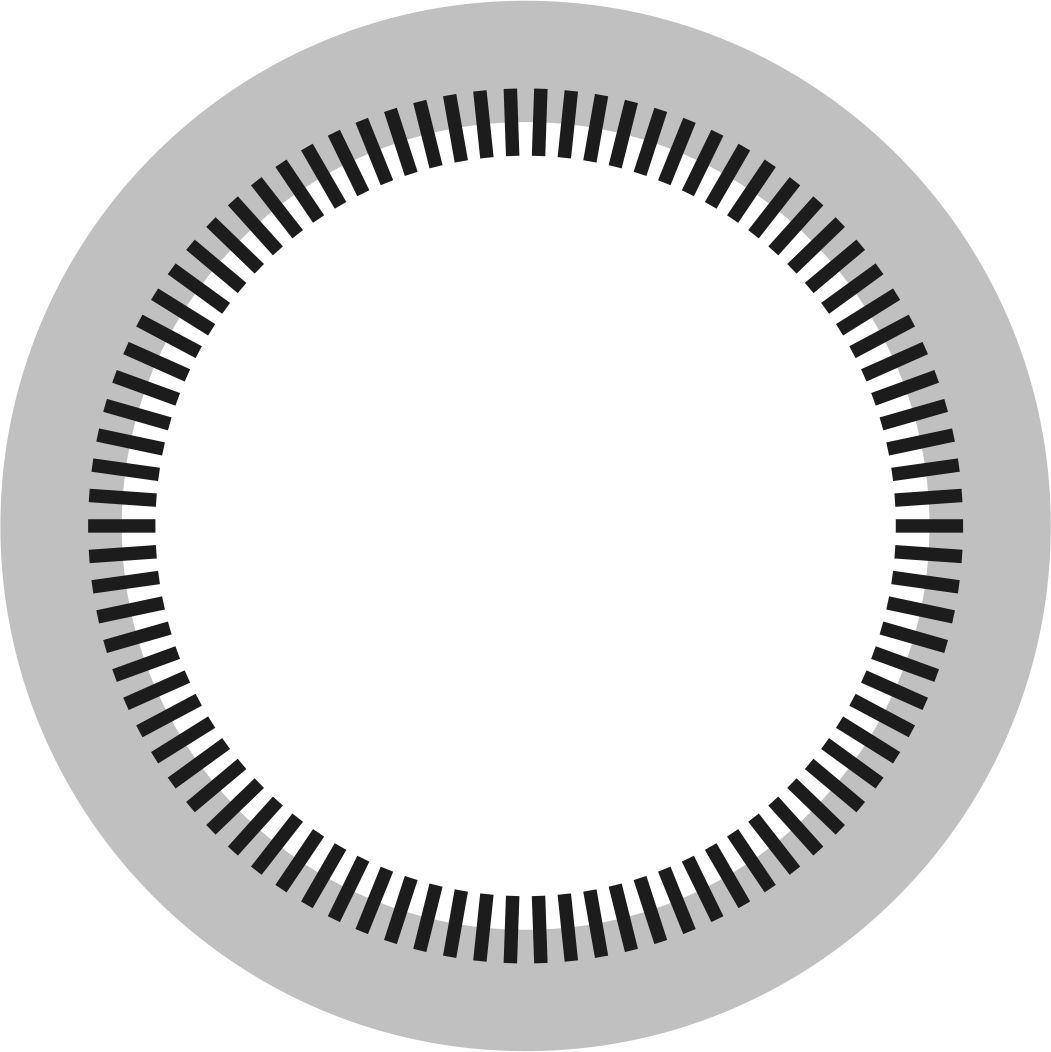

The replaceable screen is made of stainless steel and has its own features. Besides retaining particles, it must provide minimal rotation of the compressed mass and facilitate its advancement to the exit. A simple perforated screen is not suitable for such purposes, and special sieves are made of longitudinal rods surrounded by external stiffening ribs. Sliding along the rods, the mass is compressed very smoothly, and the fibers held by the screen temporarily act as a filtration material. Since filtration through the pores between particles sharply increases resistance, this acts as a limiting factor on the speed of the auger and its productivity. Too rapid pressing leads to insufficient dehydration, which cannot be overcome by blocking the outlet of the solid phase.

The replaceable screen is made of stainless steel and has its own features. Besides retaining particles, it must provide minimal rotation of the compressed mass and facilitate its advancement to the exit. A simple perforated screen is not suitable for such purposes, and special sieves are made of longitudinal rods surrounded by external stiffening ribs. Sliding along the rods, the mass is compressed very smoothly, and the fibers held by the screen temporarily act as a filtration material. Since filtration through the pores between particles sharply increases resistance, this acts as a limiting factor on the speed of the auger and its productivity. Too rapid pressing leads to insufficient dehydration, which cannot be overcome by blocking the outlet of the solid phase.

Attempts to use ordinary perforated sheet lead to a significantly larger passage of solid particles into the liquid part and difficulties in setting effective separation without clogging. Moreover, it is difficult to produce a perforated sheet with strength and perforation ratio similar to a grid made of bars. Sometimes, for separation at higher pressure, plates placed edgewise into reinforcing bands are used instead of bars. This results in a perforation ratio of 40-50% with an effective thickness of the grid being 2-3 times greater than the width of the gap between the ribs. The thickness of the banding sheet is 3-4 times larger than that for manufacturing plates, so the banding details are often made from high-strength alloy steel without regard for corrosion. Optimally, two types of grids are used simultaneously, where most of the working length is covered by a relatively weak grid with large gaps between bars, through which the main bulk of the liquid is removed. Just before the outlet, a second grid with minimal gaps between plates and minimal spacing between bands is installed to withstand the pressure of the nearly squeezed material.

Attempts to use ordinary perforated sheet lead to a significantly larger passage of solid particles into the liquid part and difficulties in setting effective separation without clogging. Moreover, it is difficult to produce a perforated sheet with strength and perforation ratio similar to a grid made of bars. Sometimes, for separation at higher pressure, plates placed edgewise into reinforcing bands are used instead of bars. This results in a perforation ratio of 40-50% with an effective thickness of the grid being 2-3 times greater than the width of the gap between the ribs. The thickness of the banding sheet is 3-4 times larger than that for manufacturing plates, so the banding details are often made from high-strength alloy steel without regard for corrosion. Optimally, two types of grids are used simultaneously, where most of the working length is covered by a relatively weak grid with large gaps between bars, through which the main bulk of the liquid is removed. Just before the outlet, a second grid with minimal gaps between plates and minimal spacing between bands is installed to withstand the pressure of the nearly squeezed material.

Reducing moisture from 85% to 65-70% at first glance does not seem very efficient. However, the bulk residue from the manure composts well due to its porous air permeability. If the material from the separator is immediately fed into drying, approximately 2 tons of water need to be evaporated to produce 1 ton of pellets. This is twice as much as drying wood, but for drying the initial paste-like mass, nearly 5 tons of moisture would have to be vaporized with corresponding fuel consumption. Thus, the screw separator with its relative simplicity and minimal electricity consumption drastically increases production efficiency and profitability.

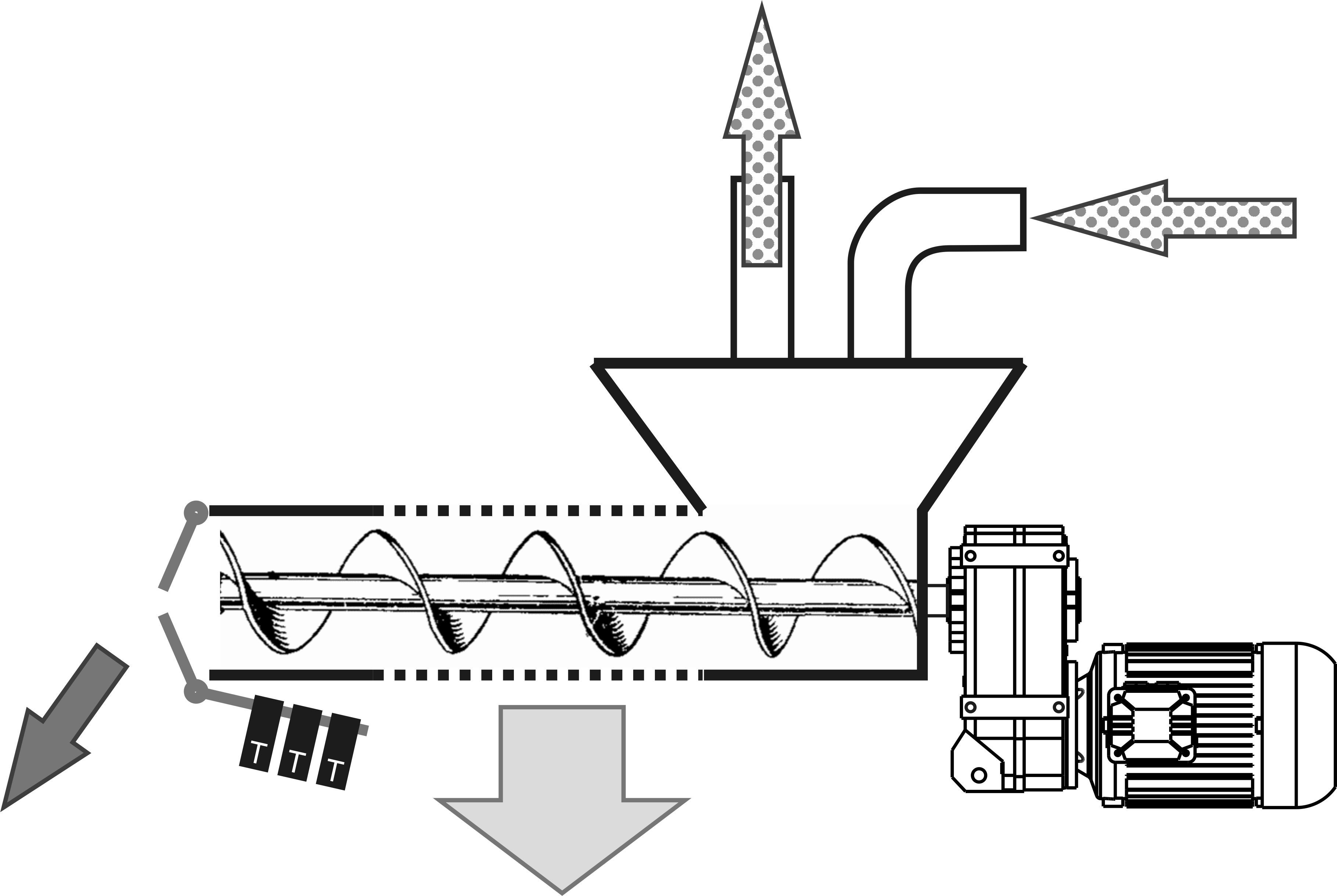

Screw separators are particularly interesting for solving the problem of chicken manure produced in cage housing. The manure is a paste-like mass with an initial moisture content of about 90-95%. The feed is provided to laying hens in finely ground form, so the efficiency of the separator grids approaches zero. With such raw material, the separator does not separate the solid and liquid phases in a full sense but only partially detaches the solid residue. Feeding the paste by normal metering is impossible, so it is diluted and squeezed, which when using external water only increases waste volume. For processing cage manure, it's necessary to organize a mixer where manure and filtrate are fed in order to reintroduce the mixture into the separator. The mixer tank should be equipped with a float switch for the periodic disposal of the liquid phase to prevent overflow.

Thus, the separation section receives manure, and within the section, the liquid portion with 90-93% moisture circulates circularly, resulting in squeezed manure and liquid excess at the output. The practice is that as it passes through the separator, the moisture content of the liquid raw material increases by only 2-3%. The table presents calculations for processing 10 tons of manure per hour.

| Mass, t. | Moisture, % | Dry Residue, tons | Water, tons | |

|---|---|---|---|---|

| At the input of the separator | 65.00 | 90.00 | 6.50 | 58.50 |

| Squeezed manure | 6.52 | 72.00 | 1.83 | 4.69 |

| Liquid part | 58.48 | 92.01 | 4.67 | 53.81 |

| Fresh Litter Feeding | 10.00 | 80.00 | 2.00 | 8.00 |

| Mixing Liquid Part | 55.00 | 92.01 | 4.40 | 50.60 |

| Excess Liquid | 3.48 | 92.01 | 0.28 | 3.20 |

Considering that when working with litter the optimal feed rate to one separator is about 10 cubic meters (2,640 gallons) per hour, it would require installing 7-8 units in a row, not just 1-2 as initially assumed from the characteristics. A significantly larger mixer, pump, and distribution system will be necessary for this setup. Simple calculation shows that the circuit handles 6.5 times the volume of waste compared to the amount of litter coming from the cages. The dry residue results in 1.83 tons (4,040 pounds) in the cake, from which about 2 tons (4,410 pounds) of pellets will eventually be produced.

In realized projects, even such substantially increased operational and investment costs eventually justify the investments, but only after 3-4 years. A separate risk is the presence of gravel in the litter, which leads to rapid wear and damage to the sieve. While the use of composite screws reduces costs and stress on the mesh, it does not completely solve the problem. It is possible to completely prevent large abrasive particles from entering the litter under two conditions: absence of gravel in the bird's diet and exceptionally high-quality concrete floors and structures throughout the technological site, from feed supply to the mixing tank.

One way to increase the efficiency of pressing is by adding medium-ground grass to the diet as a vitamin supplement. Fibers help retain and discharge small particles from the sieve into the solid residue, although coarser feeds may decrease the digestibility of mixed feed, reducing the performance metrics of meat and egg production.

Filter Press

A much more efficient device for separating fine dry residue from diluted litter, sapropel, and similar raw materials is the filter press. This device has undergone a long path of improvements and modifications from manual operation to semi-automatic functionality with filter areas calculated in tens or even hundreds of square meters (or feet).

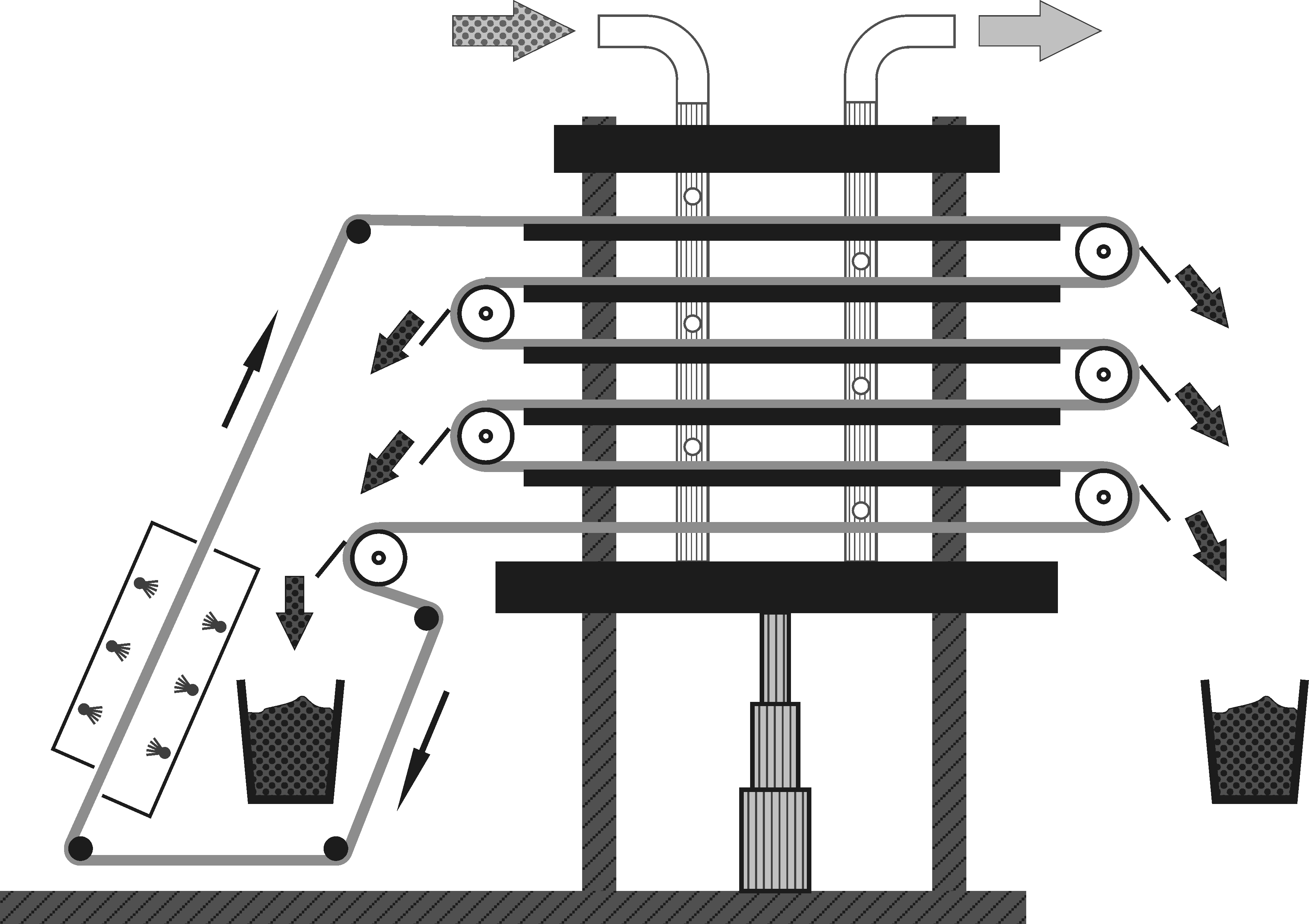

The construction of all filter presses includes two plates and a set of frames moving on guide rods. In the closed state, filtration occurs under high pressure on the cloth filter clamped between the frames. After opening, the layer of particles is scraped off by special blades mounted opposite the fabric-stretching rolls. The supply manifold has holes aligned with the frames when closed. Sometimes diaphragms are used in these setups, where water is pumped under high pressure to literally squeeze out the residue on the filter. The endless loop cloth, passing sequentially through several small frames, enters the regeneration chamber where it is thoroughly cleaned with brushes using a washing solution and dried with compressed air.

The construction of all filter presses includes two plates and a set of frames moving on guide rods. In the closed state, filtration occurs under high pressure on the cloth filter clamped between the frames. After opening, the layer of particles is scraped off by special blades mounted opposite the fabric-stretching rolls. The supply manifold has holes aligned with the frames when closed. Sometimes diaphragms are used in these setups, where water is pumped under high pressure to literally squeeze out the residue on the filter. The endless loop cloth, passing sequentially through several small frames, enters the regeneration chamber where it is thoroughly cleaned with brushes using a washing solution and dried with compressed air.

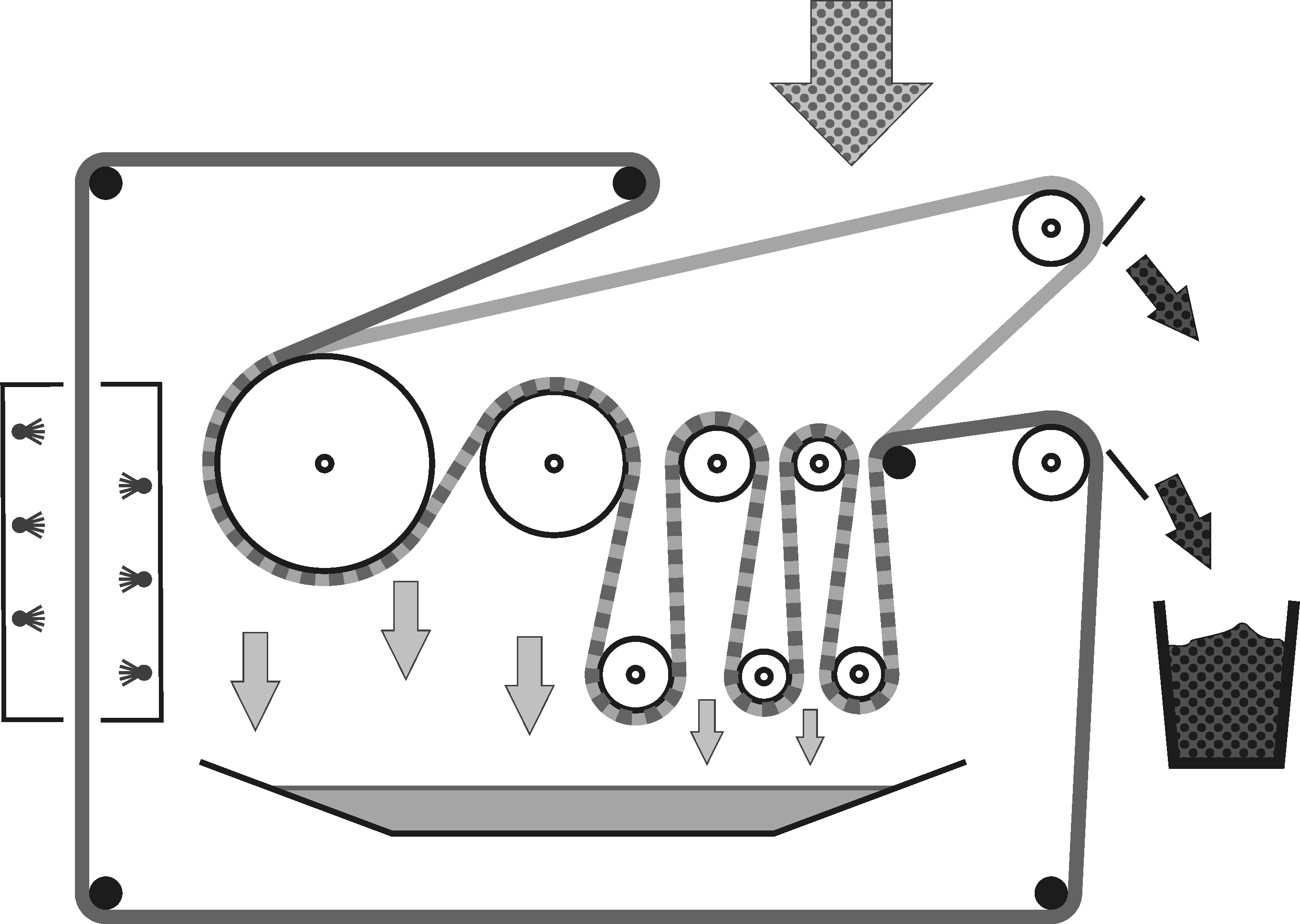

There are continuous filter presses where a paste-like raw material is captured between two cloths and squeezed by wrapping around several rolls in a tensioned state. The first roll is usually the largest in diameter for smooth and gentle squeezing of most of the liquid. The subsequent 2-5 rolls have progressively decreasing diameters, which, with stable cloth tension, increases the specific pressure due to the decrease in impact area. The removal of solid phases from the cloth and regeneration occurs similarly to a plate filter press.

There are continuous filter presses where a paste-like raw material is captured between two cloths and squeezed by wrapping around several rolls in a tensioned state. The first roll is usually the largest in diameter for smooth and gentle squeezing of most of the liquid. The subsequent 2-5 rolls have progressively decreasing diameters, which, with stable cloth tension, increases the specific pressure due to the decrease in impact area. The removal of solid phases from the cloth and regeneration occurs similarly to a plate filter press.

Roll Press

The overall moisture content of wood is divided into bound and capillary moisture. Bound moisture is absorbed into the cell walls and causes the wood to swell. Capillary moisture is contained in living cells and the capillaries that remain from them in a free state, pulling water up the tree crown. The bound moisture content for most types of wood is usually around 30%, and the rest can theoretically be squeezed out like a sponge by creating sufficient pressure. This issue is especially relevant when processing waste from productions where the technological process includes steaming wood or storing logs under water sprayers. For example, in veneer production, waste moisture content can reach 70-80%, meaning the wood is literally saturated like a sponge.

The overall moisture content of wood is divided into bound and capillary moisture. Bound moisture is absorbed into the cell walls and causes the wood to swell. Capillary moisture is contained in living cells and the capillaries that remain from them in a free state, pulling water up the tree crown. The bound moisture content for most types of wood is usually around 30%, and the rest can theoretically be squeezed out like a sponge by creating sufficient pressure. This issue is especially relevant when processing waste from productions where the technological process includes steaming wood or storing logs under water sprayers. For example, in veneer production, waste moisture content can reach 70-80%, meaning the wood is literally saturated like a sponge.

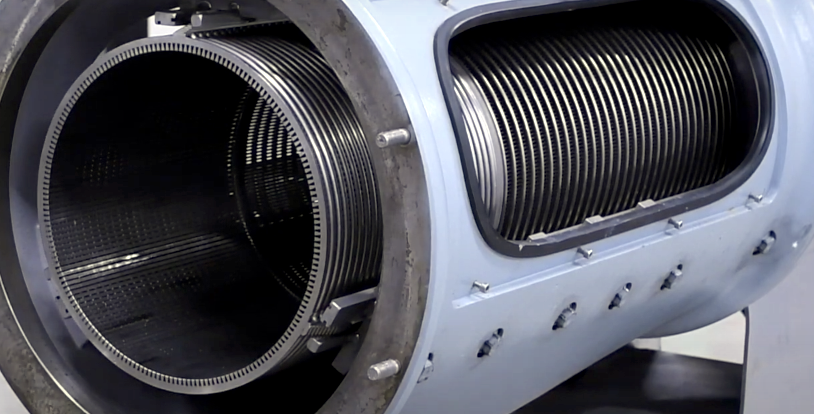

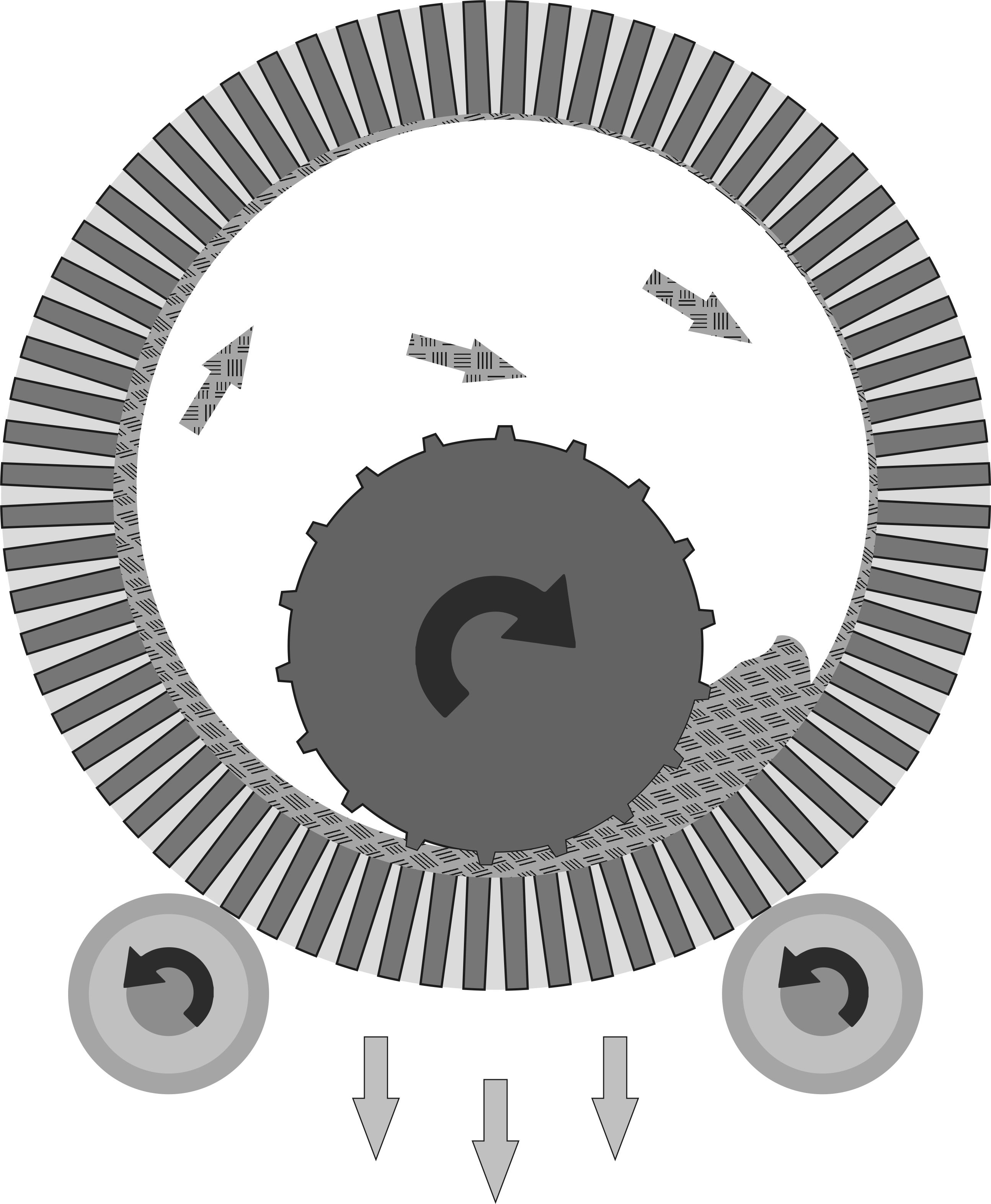

A roll press is used for squeezing fresh "green" wood. The main working parts are a cylindrical thick-walled sieve and a shaft with serrations, set at an angle of 10-15° to the horizon. The angle is chosen so that as the chips descend, they undergo compression 8-10 times. The sieve is made of several rings connected at the ends. The holes are usually conical to prevent clogging with fibers. The shaft has serrations in the form of fairly rare teeth, which ensure metered raw material capture and even layer distribution. The mat of crushed chips itself acts as a filtering material, so losses from washing away the sawdust are minimal. The liquid squeezed out after filtering is usually reused in cooking baths or for spraying on the raw material exchange.

Squeezing can reduce moisture content to 40-45%, and each ton of squeezed liquid consumes only about 40 kWh of electricity, approximately 15 times less than the heat required for evaporation. Such devices not only significantly increase drying productivity with reduced energy consumption but are also frequently used in preparing chips for biofuel power plants.