For lubrication of bearings in rollers, consistent grease with continuous consumption and extrusion of excess into the raw material is predominantly used. This necessitates the use of medical petroleum jelly-based compositions for animal feed production. For biofuel, the goal is to select the cheapest lubricant that maximally protects against scoring. Due to constant evaporation and leakage of the lubricant, powder additives are highly undesirable as particles accumulate inside the roller, quickly changing the properties of the lubricant and leading to rapid wear. Experiments with adding graphite, molybdenum sulfide, and various types of clay may initially show reduced roller temperatures for the first few hours and days, but later result in costly repairs. The champion in reducing friction and protecting bearings from hydrogen erosion is polytetrafluoroethylene, or simply Teflon. Lubricants based on Teflon show phenomenal results, but they cannot be used for biofuels. Even a small amount of fluoro- or chloro-organic compounds in the fuel leads to the release of highly toxic dioxins during combustion, negating the entire idea of biofuel as an environmentally clean energy source.

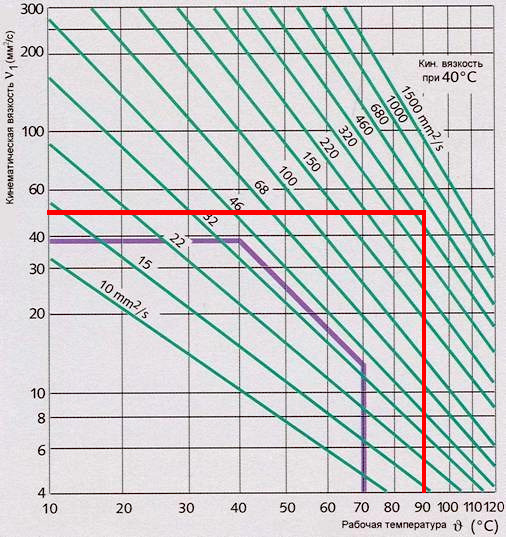

Although consistent grease appears thicker, from a technological standpoint, its lubricating properties are mainly determined by the base oil. The linear speed of rolling bodies, operating temperature, and bearing load are primarily determined. For a relatively low speed in rollers and load close to maximum, an oil viscosity of no less than 50 cSt at an operating temperature of 90°C (194°F) is required. According to the diagram, the base oil viscosity should be 460 or 680 cSt. If the grease specification indicates lower values, despite all the marketing on labels and advertisements, the grease will not perform effectively.

Although consistent grease appears thicker, from a technological standpoint, its lubricating properties are mainly determined by the base oil. The linear speed of rolling bodies, operating temperature, and bearing load are primarily determined. For a relatively low speed in rollers and load close to maximum, an oil viscosity of no less than 50 cSt at an operating temperature of 90°C (194°F) is required. According to the diagram, the base oil viscosity should be 460 or 680 cSt. If the grease specification indicates lower values, despite all the marketing on labels and advertisements, the grease will not perform effectively.

Often, the dropping point temperature is cited as one of the major technological properties of a lubricant. It is considered the maximum temperature at which the lubricant retains tackiness and thus prevents wear. This is partly true mainly for high rotation speeds under medium or low loads. Thickeners and various additives do stabilize the lubricant layer on surfaces and distribute it evenly during rotation. However, under critical loads, the size of the lubricant molecules and their ability to form an unbroken film in the contact spot play a major role. Here, the most correlating indicator is indeed the viscosity of the base oil.

Mineral oil contains relatively large and often branched molecules that prevent surface contact. The result of this structure is the main drawback, which is excessive changes in viscosity depending on temperature. The larger the molecules and the higher the base viscosity, the stronger this dependency is, as seen by the varying slopes on a diagram corresponding to different indicators. The desire to get the best for a low cost often leads to experiments with lubricants based on synthetic oils, but their properties are starkly different. The viscosity of synthetic oils is primarily determined by the length of the chains in the molecules, which are almost unbranched and therefore have very small thickness. This means that despite having the same and even superior properties such as base viscosity, dropping point temperature, resistance to washing out and oxidation, synthetic oil is completely unsuitable for use in rolls. An attempt to use such oil under critical loads results in a wear pattern that resembles water being used instead of lubrication. Of course, there are artificially created oils with large branched molecules, but their production is even more expensive than regular polyester or polyglycol-based lubricants.

There are many ways of conditionally "falsifying" lubricant, which are generally used by many manufacturers on a regular basis. The base oil may be too thick, and it is diluted with light fractions. The mixture stops working properly, as the break in the film at the contact spot shifts sharply to the properties of the diluent. In principle, the lubricant may even work normally for some time due to the addition of emulsifiers and stabilizers, but even a slight change in composition due to the accumulation of wear particles drastically alters tribological properties. Adding aerosil to increase the dropping point temperature is also popular. This additive indeed drastically reduces wear on a four-ball machine and positively impacts the seizure index. In fact, it is very fine sand, which after short work starts to clump into larger particles, causing avalanche-like wear.

A similar scenario occurs with synthetic base oils, where all indicators are better compared to mineral oils, but their best qualities emerge under short-term high loads or prolonged low loads, allowing them to handle peak moments well. However, if the constant load on a bearing exceeds 15-20 percent, mineral oil becomes indispensable, as the break load of its film at the contact spot is usually 3-5 times greater than that of polyglycol oils with similar characteristics.

The bearings of hammer mills operate at 1500 or 3000 revolutions per minute, experience shock loads, and their settled temperature reaches 70-80°C (158-176°F). A common mistake is attempting to lubricate with the same composition as used for pellet mill rollers. High viscosity effectively prevents seizures, but due to high RPMs, the lubricant overheats within a few minutes up to ignition. Therefore, even at a load of 30 percent of the nominal for these bearings at high rotation speed, a viscosity of 15-20 cSt is sufficient, which corresponds to a base oil viscosity of 100 cSt according to the diagram.

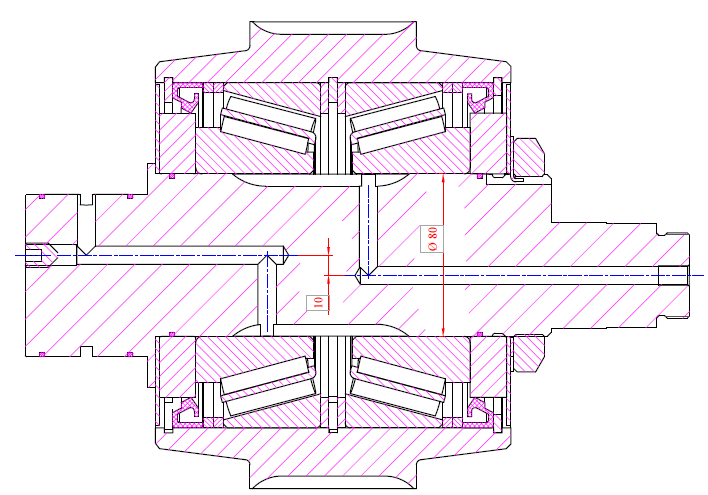

The movable seal in the rolls for applying grease comes in two types: a fluororubber seal with a spring or a labyrinth seal with a PTFE or bronze ring. Sometimes these types are combined. The seals must be resistant to high temperatures. Considering that in most pellet mills during wood processing, heating up to 120-130°C (248-266°F) is common, fluororubber is the only option for seal material. When pelleting animal feed, it may be justifiable to save costs by using ordinary Nitrile Butadiene Rubber (NBR), which becomes brittle and loses sealing properties at 120°C (248°F). The temptation to install polyurethane seals meets the impossibility of use in the presence of acids, which are released in significant quantities during wood pelleting. If the roll shaft lacks a special channel to remove excess grease, and it gets pushed out through the seal, it may be justified to install the seal with the spring facing outwards. This prevents the seal lip from turning inside out or tearing due to excess pressure in the bearing cavity. Such installation is only possible with a spring made of stainless steel, which, as it turns out, is not unusual.

A labyrinth seal without a fluororubber seal can lead to excessive grease consumption, especially when the pump is activated automatically by exceeding the temperature of the pellet mill rollers. The operator, instead of adjusting the bearings, simply refills the lubrication station more frequently. The simplest construction involves using a cap with a groove, where a PTFE or bronze ring with a slit is installed. The ring fits tightly into the edge of the shell, ensuring its fixation and rotation in the cap groove. Rings often used are standard ones from piston oil-free compressors. This type of seal primarily prevents raw material from entering the bearings but barely retains the grease flung out by centrifugal forces.

For pelleting wood flour, graphite, and other fine-particle raw materials, sealing methods are combined, making the labyrinth multi-stage. Sometimes a space remains between the roller cap and the seal, where a soft felt washer is placed. It prevents free movement of excess grease and dust, providing additional protection for the seal.

Lubrication with circulating liquid oil through the rolls, with cleaning and cooling, is the most complex method, given its clear advantages, especially in large pellet mills with a power of 250 kW (335 HP) and above. This type of system creates the best working conditions for bearings, maximizing their service life and allowing for increased productivity. The fact is that the heating of raw material during compression by the shell teeth is often excessive, and overheating limits the maximum speed of the die. If some of the heat is removed by washing inside the rolls with cooled and filtered oil, it allows production to increase by 15-20% just by increasing the rotation speed. Meanwhile, the specific energy consumption per ton of product increases insignificantly, as the increase in energy consumption by the pellet mill is offset by reduced specific costs on most other units of the pelleting line.

A somewhat exotic but quite effective method is liquid lubrication of the rolls by head pressure from a tank. Seals are installed, and liquid oil is introduced directly into the channels of the eccentric shafts with minimal pressure. The oil tank is located about 1 meter (3 feet) above the pressing unit, and a drip chamber is integrated into the tube for flow control. As the flow increases, the operator checks the condition of the bearings and seals. This system allows the use of fairly cheap mineral oil and even purified waste oil under low loads.