The material for making dies and shells needs to be both hard enough for wear resistance and have a high elongation before breaking to resist cracking. These two properties are somewhat mutually exclusive in many types of inexpensive steel grades. High-carbon and manganese steels become brittle after hardening, whereas ductile low-alloy grades cannot usually be hardened beyond 40 HRC, even with oil quenching. Additionally, corrosion resistance is important for dies since the pelleting of wood involves initial stages of pyrolysis due to local frictional heating. This process releases formic and acetic acids. Even small amounts of these chemically active emissions in the steamy environment quickly form iron oxides on the die surface, disrupting their gloss and causing difficult start-ups even after stops of just a few hours. The use of a conservation mixture of material with oil helps combat this issue, but doesn't eliminate it completely. High-carbon steels have a notable drawback under these conditions: the coarse carbide grains within the material structure create micropores that allow water and acid vapors to penetrate. This corrosion leads to the flaking off of microparticles, and the die may crack halfway through its service life as the process expands.

After many years of experiments, the most popular steel grades for forgings have been identified as 46Cr13 and 20CrMnTi. The first is easily hardenable throughout most of its volume due to its high chromium and carbon content. High-chromium steels are corrosion-resistant, and these dies are often mistakenly called stainless. In reality, they do rust, but very slowly. Hardening takes place in special vacuum furnaces or in specialized gaseous environments that prevent carbon from burning off the surface layers. The second type of steel is conditionally referred to as black because their hardening process involves immersion in an oil bath. This carbonizes the surface layer to a depth of 3-5 mm (0.12-0.20 inches) achieving maximum hardness in that layer. The remaining body of the die maintains a sufficient hardness of 40-45 HRC, with the introduction of titanium making it quite resistant to cracking. Dies of this steel are 10-30% cheaper, and the lack of corrosion resistance is acceptable for continuous 24/7 operation. The service life of a 46Cr13 die is on average 1.5 times longer, precisely because of the depth of hardening, as the wear track typically requires about a 10 mm (0.4 inches) depth determination.

After many years of experiments, the most popular steel grades for forgings have been identified as 46Cr13 and 20CrMnTi. The first is easily hardenable throughout most of its volume due to its high chromium and carbon content. High-chromium steels are corrosion-resistant, and these dies are often mistakenly called stainless. In reality, they do rust, but very slowly. Hardening takes place in special vacuum furnaces or in specialized gaseous environments that prevent carbon from burning off the surface layers. The second type of steel is conditionally referred to as black because their hardening process involves immersion in an oil bath. This carbonizes the surface layer to a depth of 3-5 mm (0.12-0.20 inches) achieving maximum hardness in that layer. The remaining body of the die maintains a sufficient hardness of 40-45 HRC, with the introduction of titanium making it quite resistant to cracking. Dies of this steel are 10-30% cheaper, and the lack of corrosion resistance is acceptable for continuous 24/7 operation. The service life of a 46Cr13 die is on average 1.5 times longer, precisely because of the depth of hardening, as the wear track typically requires about a 10 mm (0.4 inches) depth determination.

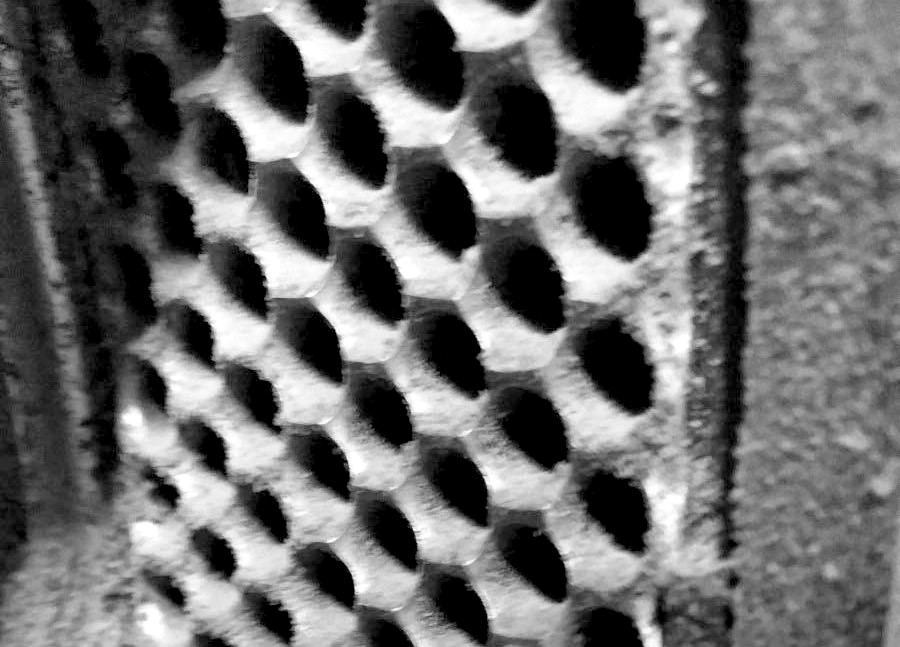

There is a noticeable negative perception of black dies because equipment suppliers, attempting to save costs, ordered dies from China at the lowest possible prices made from 20CrMnTi steel. The issue was not just the material itself but mainly the quality of machining. According to the proper technology, all holes, counterbores, and countersinks should first be drilled on a multi-spindle machine, leaving a small allowance on the working surface of the channels. The second step involves passing all channels with gun drills, which leave minimal burrs with an almost perfect surface. In the third step, the die is installed in a machine similar to a pellet mill, and a polishing mixture of sawdust, oil, and fine abrasive paste is passed through it to achieve a mirror surface. Each stage contributes 15 to 30% to the processing cost. Thus, the cheapest dies resulted from simple drilling, leaving burrs from the drill on the surface that resemble threaded fasteners. To combat this, a polishing mixture is run through the pellet mill, but this usually only helps when working with soft materials. Sawdust clogs such holes, leading to endless emergency shutdowns. The most frustrating part is that even after using the polishing mixture, smooth recesses form where the burrs were, which also hinder stable operation and lead to inconsistent pellet quality. Additionally, feeding the abrasive mixture into the pellet mill results in accelerated wear of the shells and die, as well as the seals and bearings.

There is a noticeable negative perception of black dies because equipment suppliers, attempting to save costs, ordered dies from China at the lowest possible prices made from 20CrMnTi steel. The issue was not just the material itself but mainly the quality of machining. According to the proper technology, all holes, counterbores, and countersinks should first be drilled on a multi-spindle machine, leaving a small allowance on the working surface of the channels. The second step involves passing all channels with gun drills, which leave minimal burrs with an almost perfect surface. In the third step, the die is installed in a machine similar to a pellet mill, and a polishing mixture of sawdust, oil, and fine abrasive paste is passed through it to achieve a mirror surface. Each stage contributes 15 to 30% to the processing cost. Thus, the cheapest dies resulted from simple drilling, leaving burrs from the drill on the surface that resemble threaded fasteners. To combat this, a polishing mixture is run through the pellet mill, but this usually only helps when working with soft materials. Sawdust clogs such holes, leading to endless emergency shutdowns. The most frustrating part is that even after using the polishing mixture, smooth recesses form where the burrs were, which also hinder stable operation and lead to inconsistent pellet quality. Additionally, feeding the abrasive mixture into the pellet mill results in accelerated wear of the shells and die, as well as the seals and bearings.