Adjusting the moisture level of raw material can be achieved in various ways depending on the peripheral equipment, adjustment capabilities, and characteristics of the material. Ideally, the moisture content of the raw material is adjusted in the dryer, and its fluctuations are within 1%. However, on basic dryers, it is often simpler to over-dry the material and then add water due to uneven initial moisture. Water flow regulation is carried out either by a needle valve with visual monitoring through a rotameter or by stepwise activation of multiple nozzles.

Adjusting the moisture level of raw material can be achieved in various ways depending on the peripheral equipment, adjustment capabilities, and characteristics of the material. Ideally, the moisture content of the raw material is adjusted in the dryer, and its fluctuations are within 1%. However, on basic dryers, it is often simpler to over-dry the material and then add water due to uneven initial moisture. Water flow regulation is carried out either by a needle valve with visual monitoring through a rotameter or by stepwise activation of multiple nozzles.

Using a rotameter in both cases makes it quite easy to calculate the water usage per ton of product and to understand how much additional moisture is needed. For example, if at a production rate of 1 ton per hour, a reasonably quality pellet is adjusted with a water supply of 50 liters per hour (13.2 gallons per hour), a rough estimate indicates a shortage of 5% moisture, which is quite significant and likely results in a less attractive pellet. You should dry to a higher moisture level to reduce water supply to 20-30 liters per hour (5.3-7.9 gallons per hour) while simultaneously increasing the dryer’s productivity, as more under-dried material will result from increased feed rate into the dryer. Raising moisture from 5% to 10% solely by increasing the feed rate into the dryer can yield a 10-15% productivity gain, which is already quite significant over monthly or yearly production scales. Utilizing a rotameter also provides clear instructions for operators during equipment adjustment training: each parameter can be described in numerical terms, making the repeatability of the result understandable even for beginners.

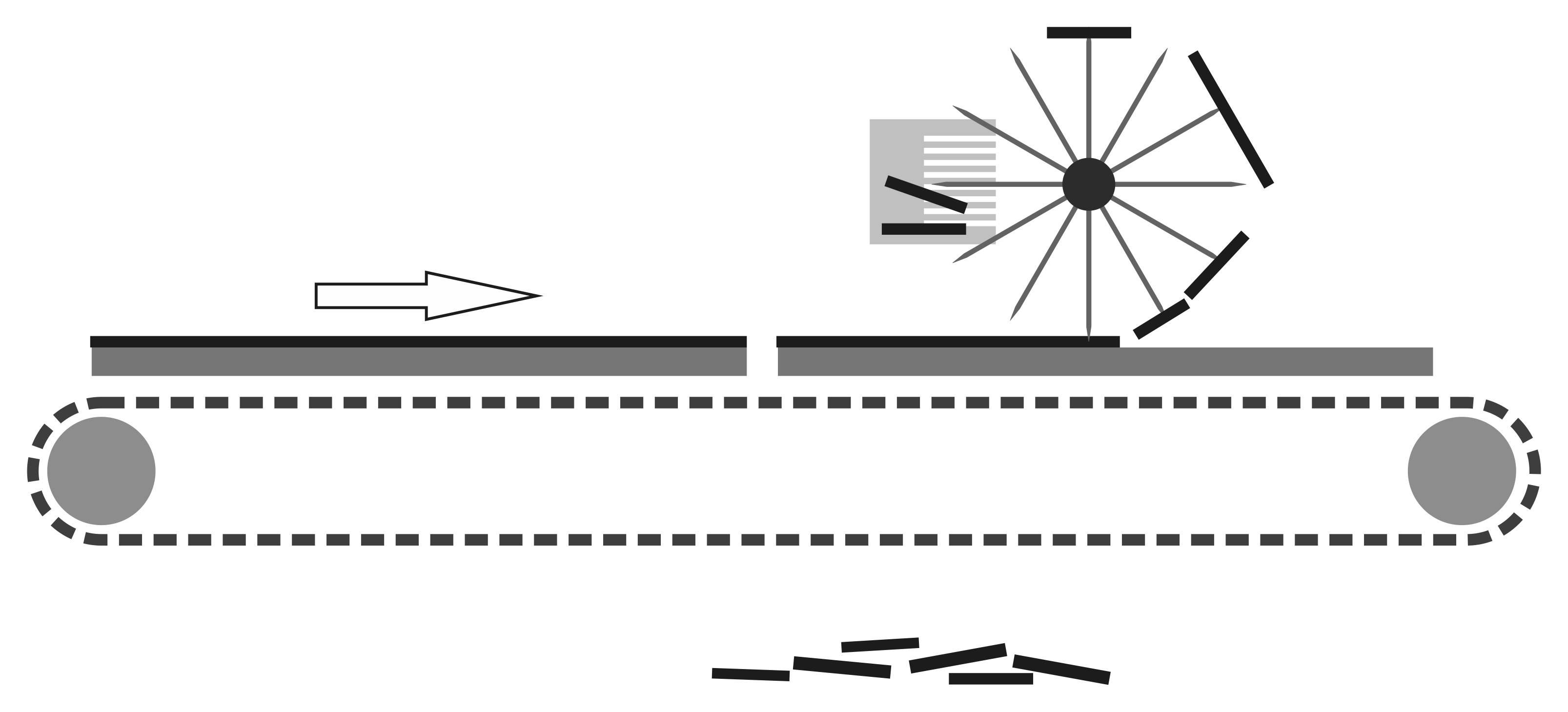

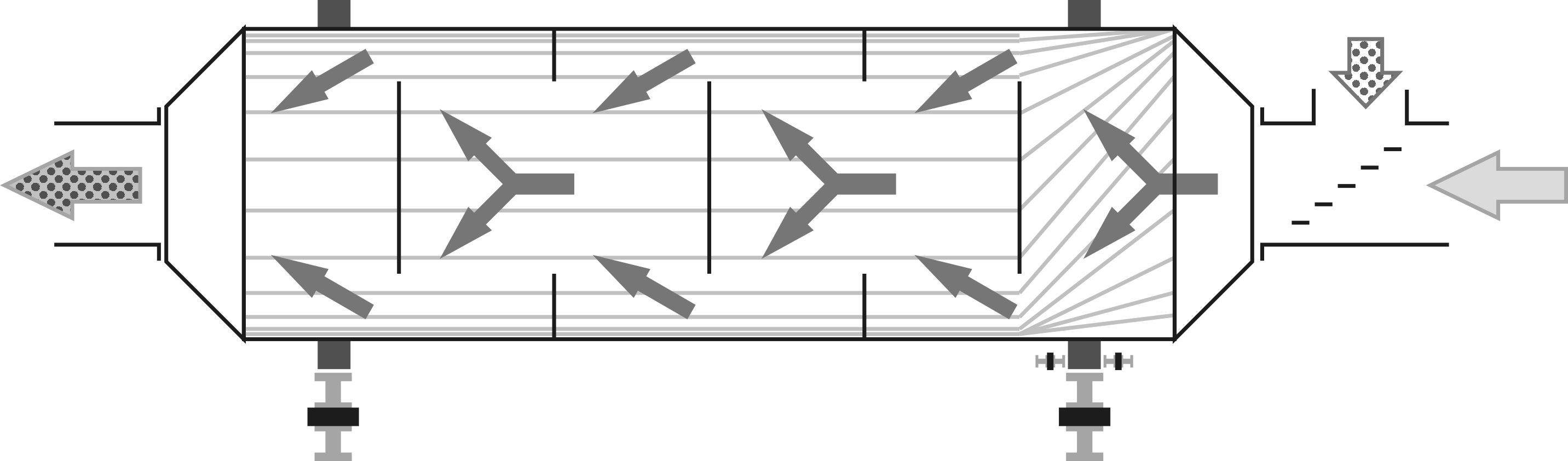

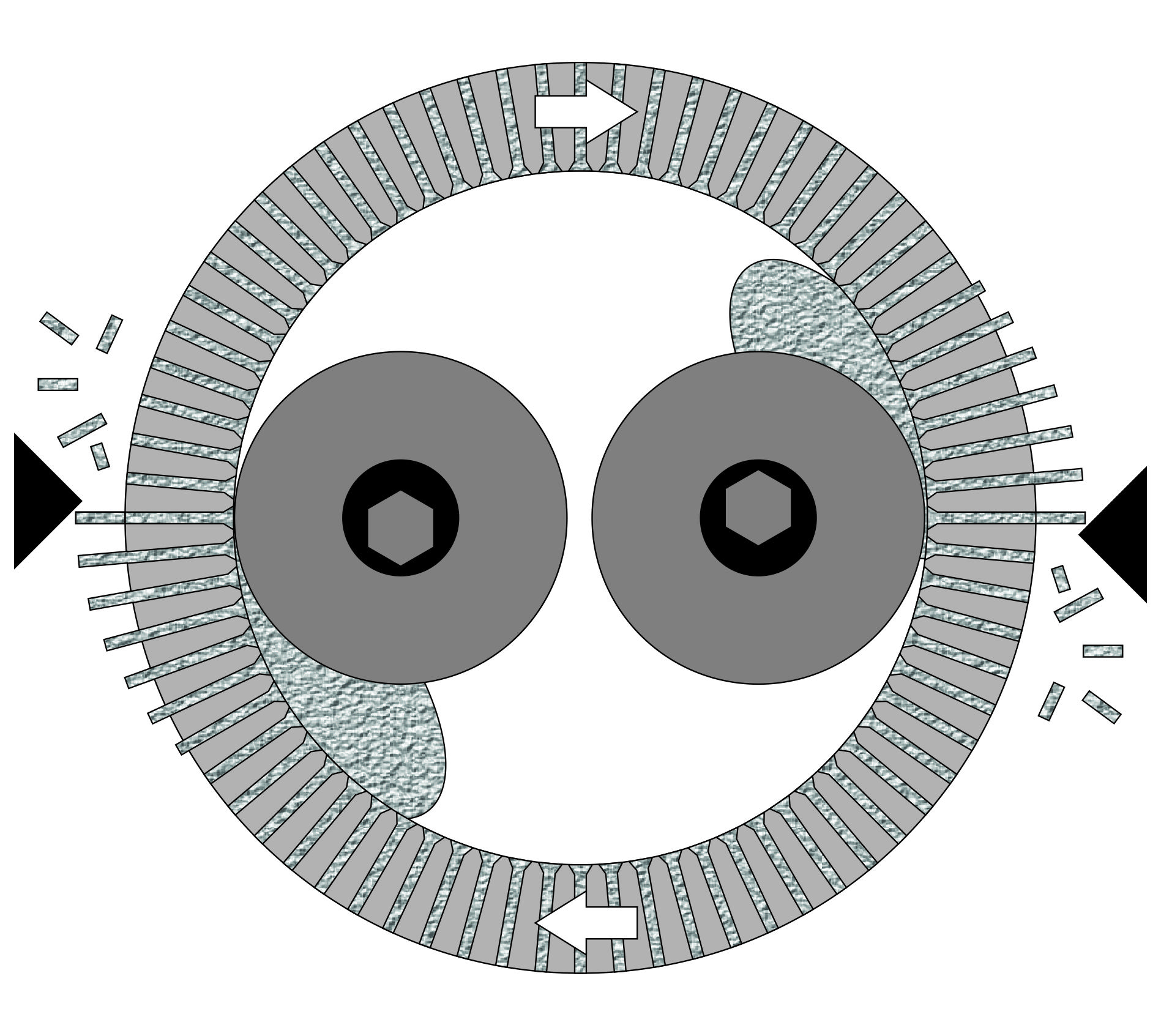

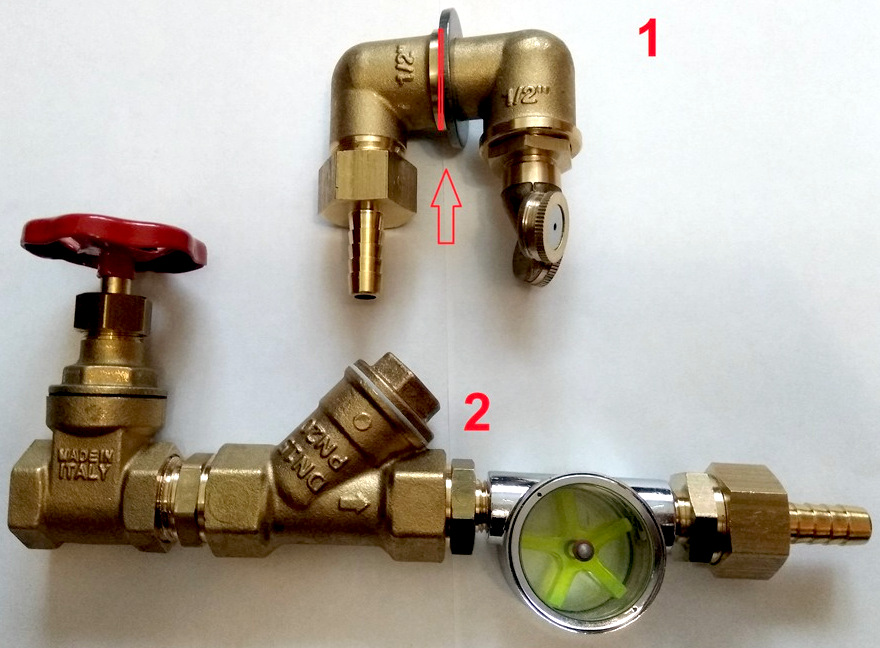

Sometimes, instead of a rotameter, a simple flow visual indicator with a paddle is installed, which allows one to notice flow stoppage when the spray nozzle is clogged and approximately gauge the intensity of moistening by the paddle's rotation frequency. This simplified option is quite sufficient for starting a pelletizing line and bringing the dryer to the desired parameters with subsequent full shutting off of the water supply. In the illustration, part #1 is installed on the mixer-conditioner, and part #2 is placed in direct proximity to the control panel that regulates the raw material supply to the pellet mill. The working position of the nozzle should be such that the holes are facing downwards if possible. This significantly reduces the tendency to clog with material. If a mixer or another moving part is located near the nozzle, the holes should face in the direction of movement.

Sometimes, instead of a rotameter, a simple flow visual indicator with a paddle is installed, which allows one to notice flow stoppage when the spray nozzle is clogged and approximately gauge the intensity of moistening by the paddle's rotation frequency. This simplified option is quite sufficient for starting a pelletizing line and bringing the dryer to the desired parameters with subsequent full shutting off of the water supply. In the illustration, part #1 is installed on the mixer-conditioner, and part #2 is placed in direct proximity to the control panel that regulates the raw material supply to the pellet mill. The working position of the nozzle should be such that the holes are facing downwards if possible. This significantly reduces the tendency to clog with material. If a mixer or another moving part is located near the nozzle, the holes should face in the direction of movement.

There are electronic rotameters, which essentially consist of a visual indicator with a paddle, on one blade of which a neodymium magnet is embedded. Outside the glass, a sensor reads the rotations, and this analog signal is then sent to the equipment control controller or to a separate calibrated meter displaying the water flow rate in real time.

When using multiple nozzles, stepped switching is enabled, and the humidity of the raw material fed into the pellet mill and pellets is assessed visually. This is more convenient for experienced operators and for remote control. One nozzle sprayer with an orifice diameter of 1 mm and a pressure of 2.5 bar can produce about 50 liters (13 gallons) of water mist per hour. Sprayer plates are available with a variety of orifice diameters, and the water flow through them at the same pressure is roughly proportional to the nozzle diameter. When the orifice is smaller than 0.8 mm, clogging issues are more common because any sawdust entering may not be flushed out by the water pressure. With an orifice diameter greater than 1.2 mm, the spray quality may decrease when set to a low water flow.

When using multiple nozzles, stepped switching is enabled, and the humidity of the raw material fed into the pellet mill and pellets is assessed visually. This is more convenient for experienced operators and for remote control. One nozzle sprayer with an orifice diameter of 1 mm and a pressure of 2.5 bar can produce about 50 liters (13 gallons) of water mist per hour. Sprayer plates are available with a variety of orifice diameters, and the water flow through them at the same pressure is roughly proportional to the nozzle diameter. When the orifice is smaller than 0.8 mm, clogging issues are more common because any sawdust entering may not be flushed out by the water pressure. With an orifice diameter greater than 1.2 mm, the spray quality may decrease when set to a low water flow.

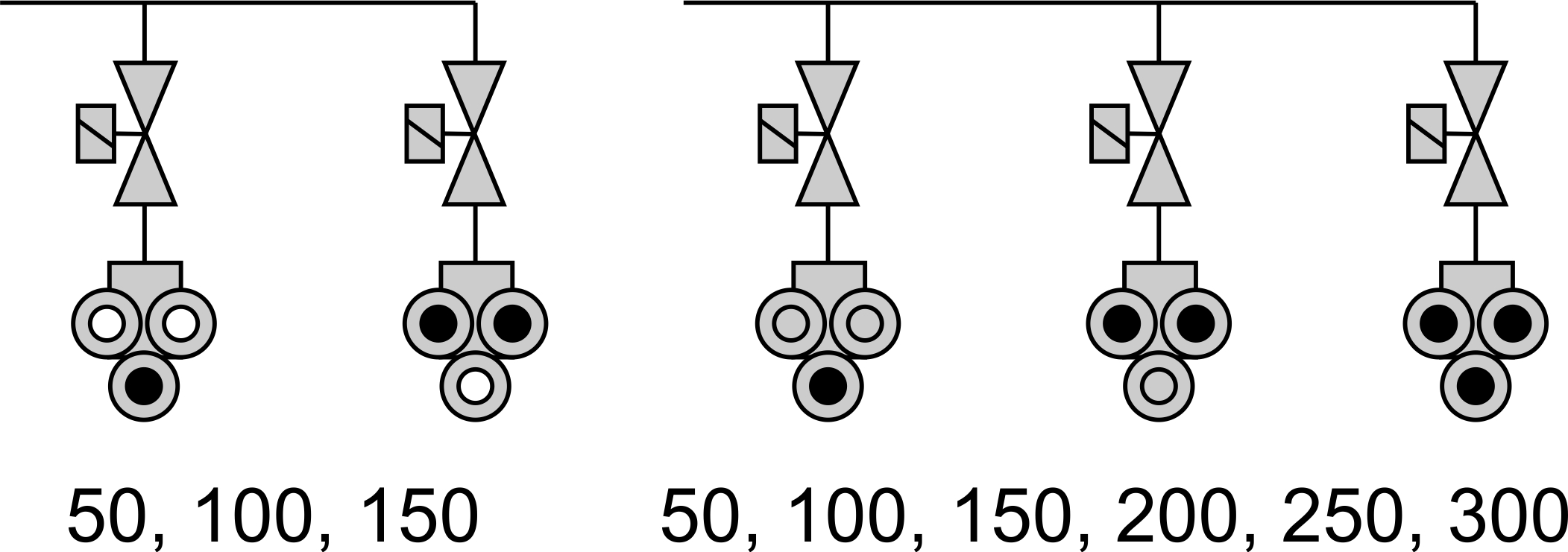

If you install two different nozzles, where one has one sprayer and the other has two, it is possible to stepwise adjust the water flow to 50, 100, or 150 liters (13, 26, or 40 gallons) per hour using two control buttons. To avoid complicating inventory, it is better to purchase nozzles with three sprayers and block any unused ones with regular tape. Using three nozzles with three solenoid valves allows a six-step flow regulation.

If the valves are controlled by a programmable controller rather than buttons, two additional interesting options become available. First, intermittent water delivery through a nozzle with one sprayer at intervals of 10-20 seconds allows finer step division and more precise dosing. This interval will have little impact on the pelleting process because the fluctuations in moisture delivery will smooth out as the material passes through the mixer-conditioner, and layers with slightly different moistures will lay thinly on the die. Second, you can program idle nozzles to activate for 1 second every 3-5 minutes, preventing sawdust clogs. Adding in-line moisture meters to such a system allows fully automatic operator workflows.

If the valves are controlled by a programmable controller rather than buttons, two additional interesting options become available. First, intermittent water delivery through a nozzle with one sprayer at intervals of 10-20 seconds allows finer step division and more precise dosing. This interval will have little impact on the pelleting process because the fluctuations in moisture delivery will smooth out as the material passes through the mixer-conditioner, and layers with slightly different moistures will lay thinly on the die. Second, you can program idle nozzles to activate for 1 second every 3-5 minutes, preventing sawdust clogs. Adding in-line moisture meters to such a system allows fully automatic operator workflows.

It is important that the water pressure remains stable. A fluctuation of more than 7.25 psi can cause significant changes in the material's moisture content, resulting in either poor pellet quality or periodic emergency shutdowns due to die coking. Therefore, when supplying water from a small home pumping station, it should be equipped with a larger receiver tank and a sensitive pressure sensor. In field conditions, the simplest way to achieve stable pressure is to have the station circulate water through a half-closed ball valve. Adjust the valve handle so that the station runs continuously without turning off. This will reduce the station's lifespan but will allow operation without a pressure sensor.